Simrad GC80/85 Double System Controller

988-12721-001

23

Do not use a megger etc., for insulation test of the system. Using a megger

can break internal electric parts.

Always disconnect wirings connected to the system before testing related

power distribution lines with a megger.

5.3 Cleaning the operator panels and the cabinet surface

The surface of the display is likely to keep foreign materials due to

electrification.

Use a vacuum cleaner with a soft brush to avoid damaging the buttons

and the panel. If required, clean the buttons and panel with a non-abrasive

cloth moistened with mild soap solution.

5.4 Check warning label

Check and clean warning labels to read legibly.

5.5 Checking the connectors

The connectors should be checked by visual inspection only. Push the

connector plugs into the connector. If the connector plugs are equipped

with a lock, ensure that this is in the correct position.

5.6 Checking mechanical installation

Vibration and shock may cause mechanical parts to loosen. All fastening

screws should therefore be checked regularly and eventually tightened.

5.7 Preventive maintenance intervals

Local evaluations should be made to determine site-specific maintenance

intervals.

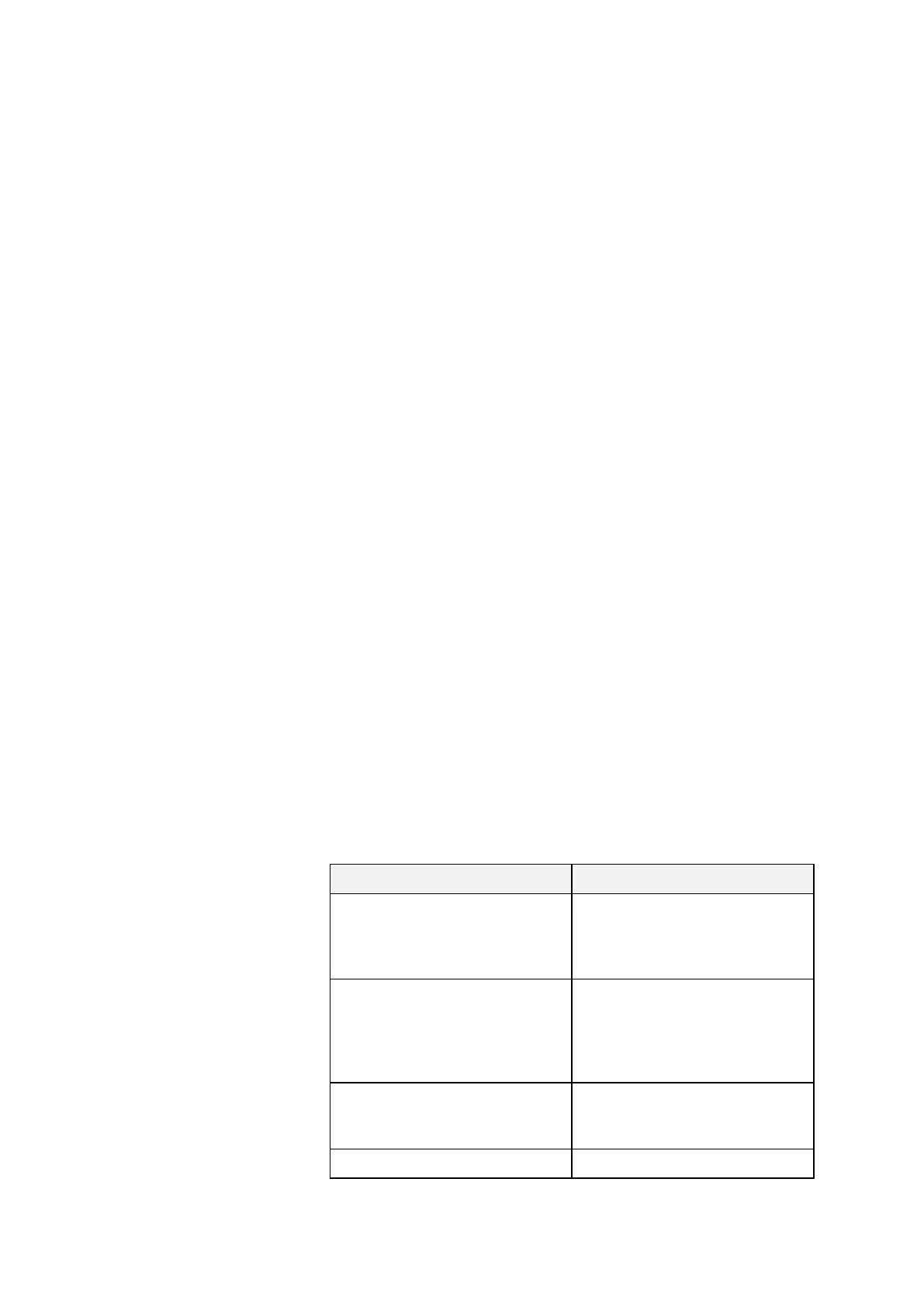

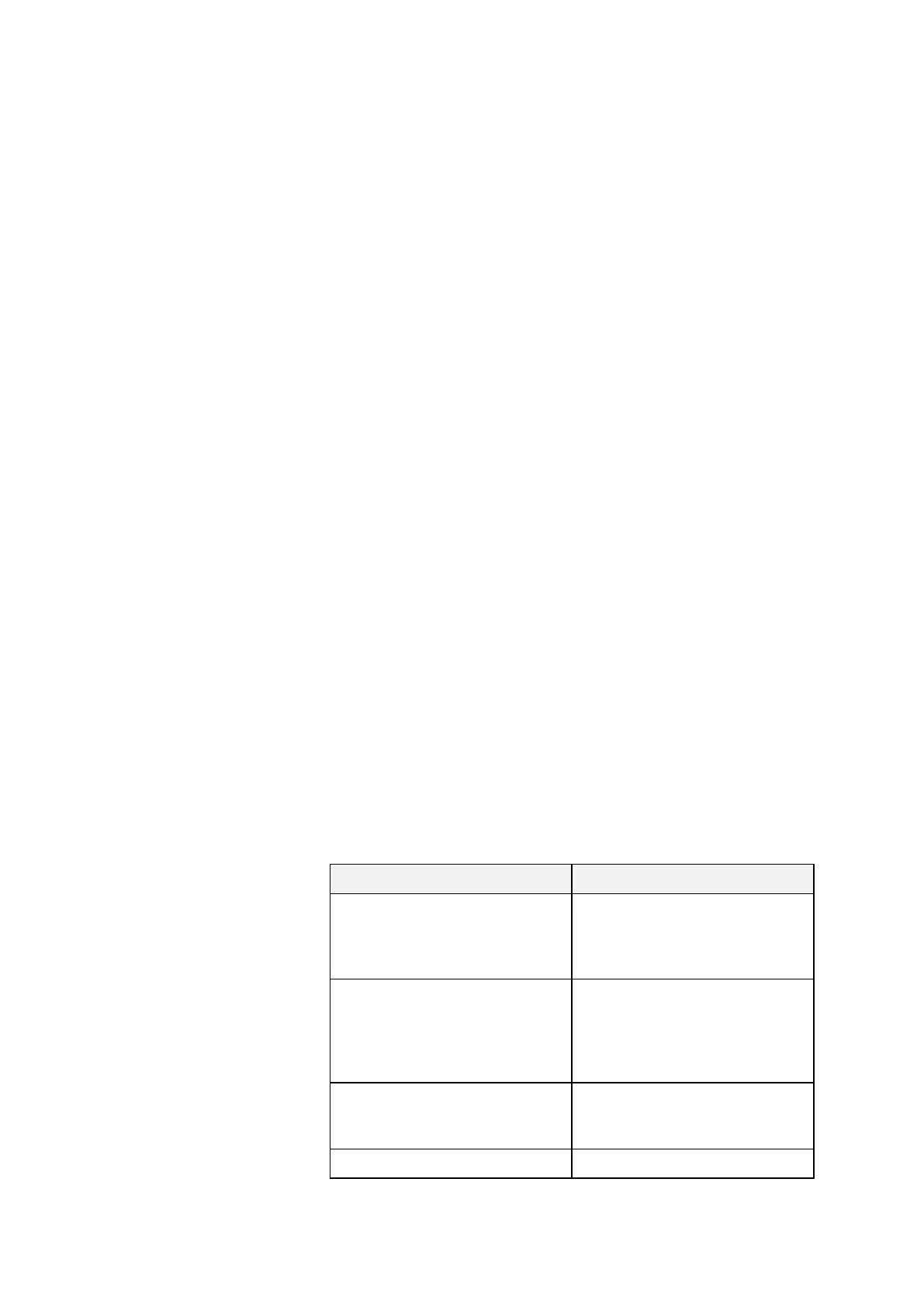

ACTION INTERVAL RECOMMENDED

Confirm that the value of each

repeater synchronizes with the

displayed true bearing on the

operating panel.

Daily

Confirm that the displayed latitude

and speed are according to the

vessel’s actual latitude and speed.

Refer to “Heading sensor parameter

check” on page 23.

Daily

Confirm that the vessel’s power

supply voltage is stable within

specifications.

Daily

Check connectors. Every 6 months

Loading...

Loading...