conducted as chapter entitled “Tension

measurement

●

The fixed lower part of the auto tensioner

has a minimum/maximum indicator.

●

If the indicator is found to be beyond the

minimum/maximum range upon visual in-

spection, the belt layout components must

be checked.

Tension measurement

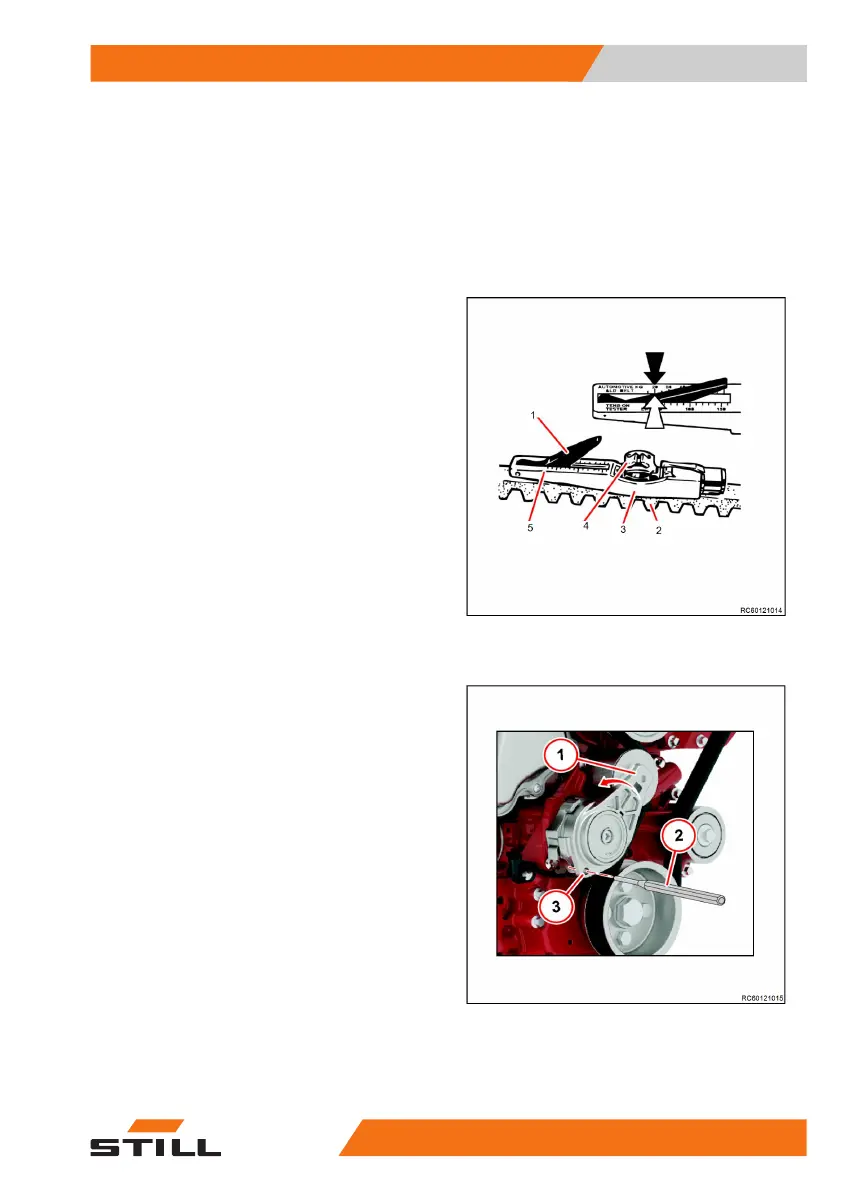

– Lower indicator arm (1) into the measuring

device.

– Place guide (3) between two belt pulleys on

the V-belt (2). The stop must be at the side.

– Press the button (4) at right angles to the V-

belt (2) evenly until you hear or feel the

spring snap in.

– Lift the measuring device carefully without

altering the position of the indicator arm (1).

– Read the measured value at the point of in-

tersection (arrow), scale (5)and indicator

arm (1).

– Retighten and repeat the measurement if

necessary.

Replacing the V-belt

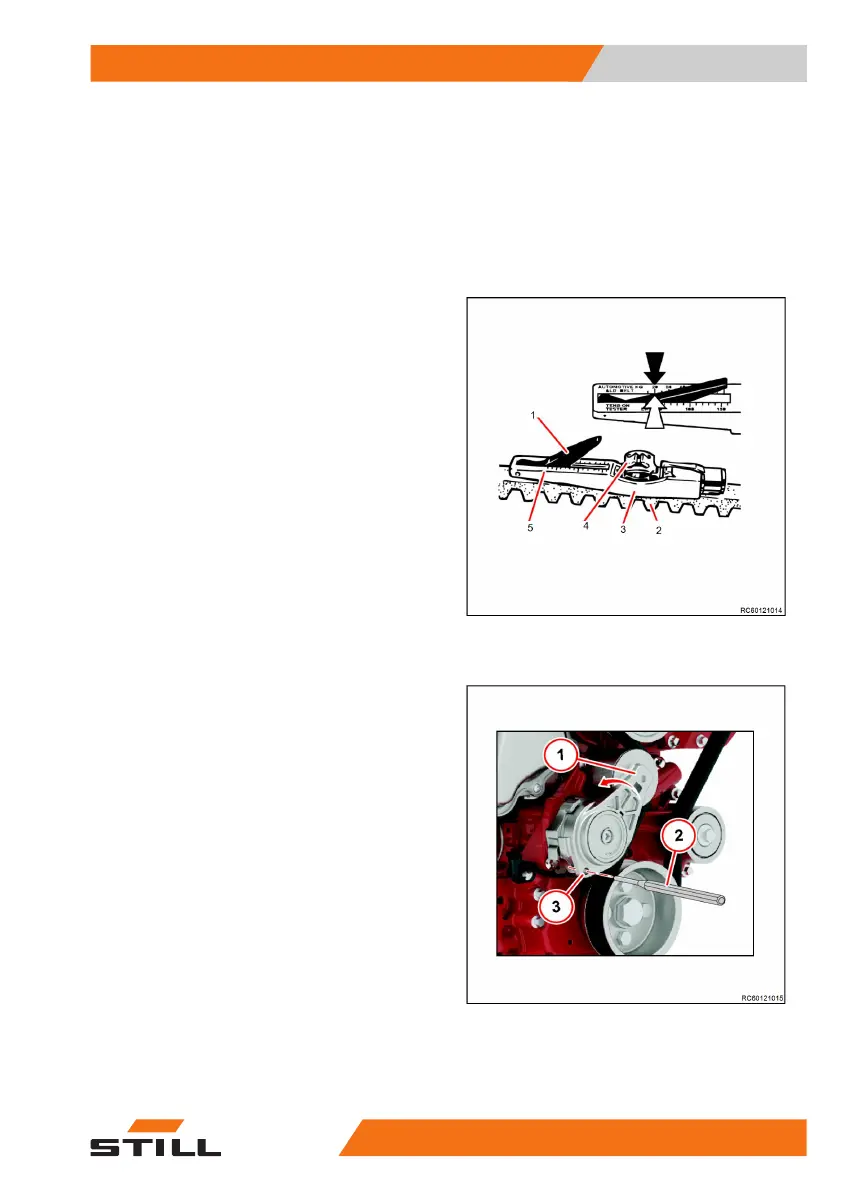

– Press tensioning roller with socket wrench

in the direction of the arrow until a retaining

pin can be fixed in the assembly bore. The

V-ribbed belt is now tension free

– First pull the V-ribbed belt off the smallest

roller or off the tensioning roller.

– Mount new V-ribbed belt.

– Retain tensioning pulley (1) using the pin

wrench and remove the holding pin.

– Tension V-ribbed belt using the tensioning

roller and socket wrench. Check whether

the V-ribbed belt is correctly in its guide.

Tension pulley

Retaining pin

Assembly bore

1

2

3

Maintenance

5

Maintenance service

12960128011601 EN - 03/2020

Loading...

Loading...