I

CAMSHAFT

MECHANICAL

B:

INSTALLATION

1)

Camshaft installation:

Apply engine oil to the cylinder head at camshaft

bearing location before installing the camshaft. In-

stall the camshaft

so that each valves is close to or

in contact with “base circle” of cam lobe.

CAUTION:

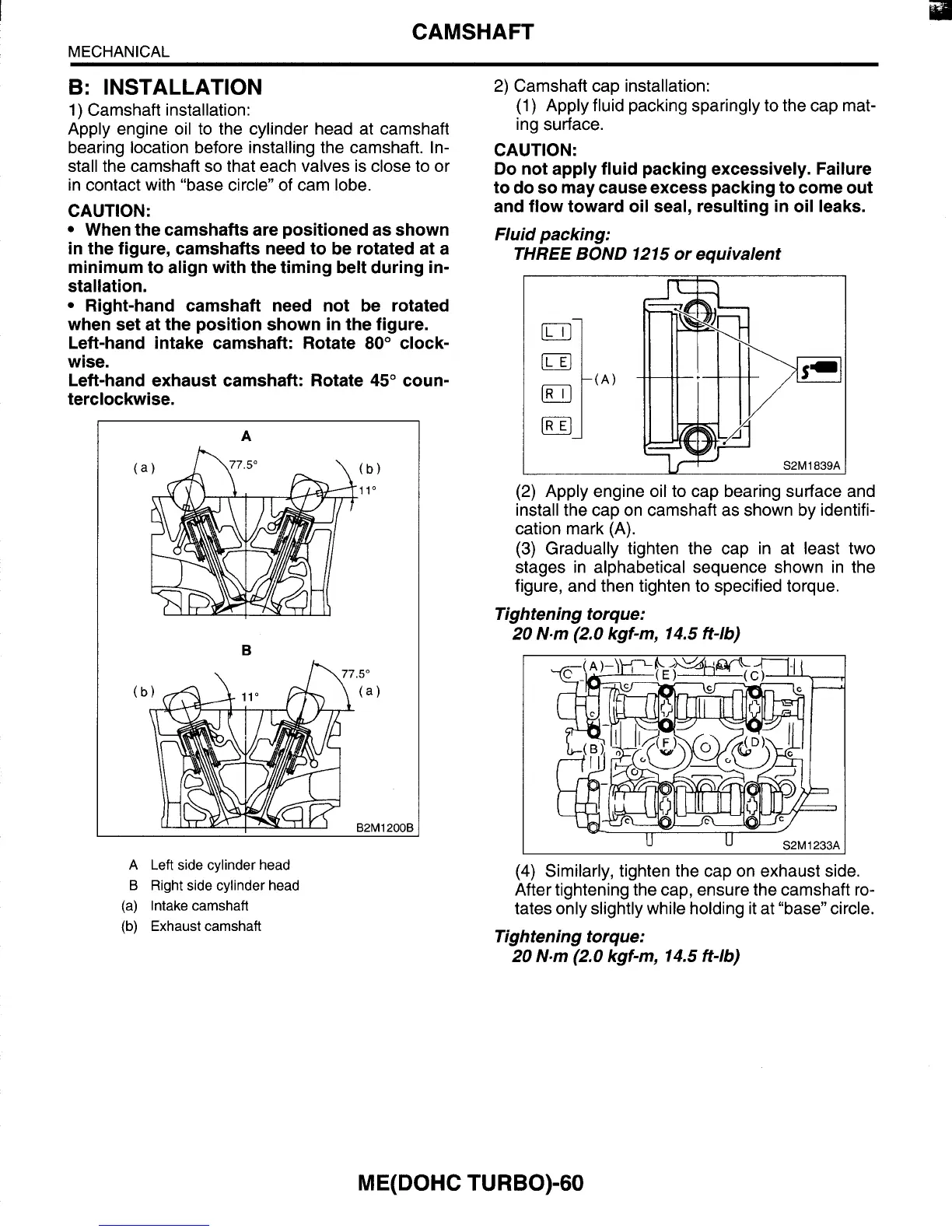

When the camshafts are positioned as shown

in the figure, camshafts need to be rotated at a

minimum to align with the timing belt during in-

stallation.

Right-hand camshaft need not be rotated

when set at the position shown

in

the figure.

Left-hand intake camshaft: Rotate

80”

clock-

wise.

Left-hand exhaust camshaft: Rotate

45”

coun-

terclockwise.

A

h

2)

Camshaft cap installation:

(1)

Apply fluid packing sparingly to the cap mat-

ing surface.

CAUTION:

Do

not apply fluid packing excessively. Failure

to do

so

may cause excess packing to come out

and flow toward oil seal, resulting

in

oil leaks.

Fluid packing:

THREE BOND 1215

or

equivalent

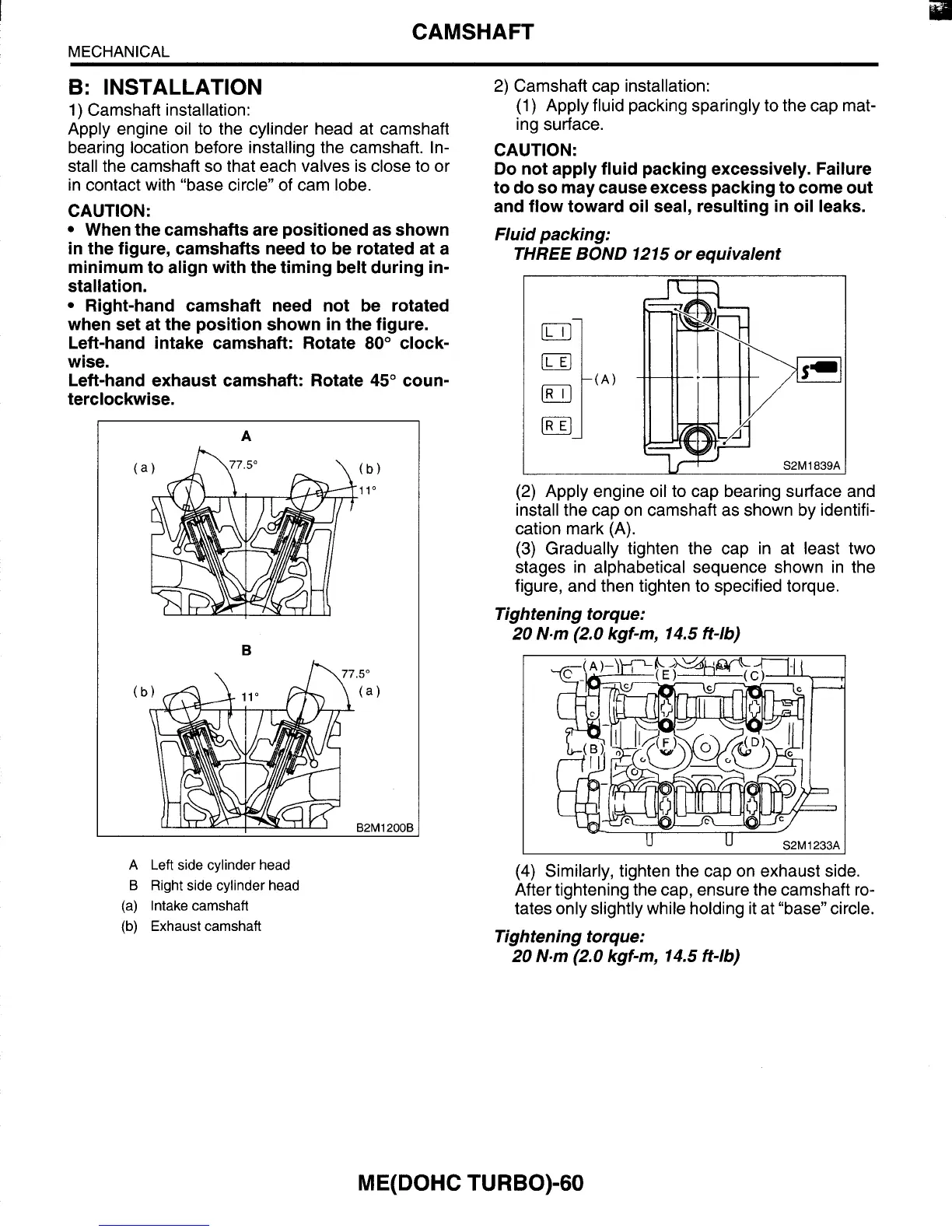

(2)

Apply engine oil to cap bearing surface and

install the cap on camshaft as shown by identifi-

cation mark (A).

(3)

Gradually tighten the cap in at least two

stages in alphabetical sequence shown in the

figure, and then tighten to specified torque.

20 N.m (2.0 kgf-m, 14.5 ft-16)

Tightening torque:

I

U

U

S2M

1233A

A

Left

side

cylinder

head

B

Right

side cylinder

head

(a)

Intake camshaft

(b)

Exhaust

camshaft

(4)

Similarly, tighten the cap on exhaust side.

After tightening the cap, ensure the camshaft ro-

tates only slightly while holding it at “base” circle.

20 Nom (2.0 kgf-m, 14.5 ft-16)

Tightening torque:

ME(D0HC

TURBO)-60

Loading...

Loading...