IM-LYOQUEST-EN-2101 14 / 58

8.2.2. In chamber

The product may be freeze-dried inside the condenser or in the chamber:

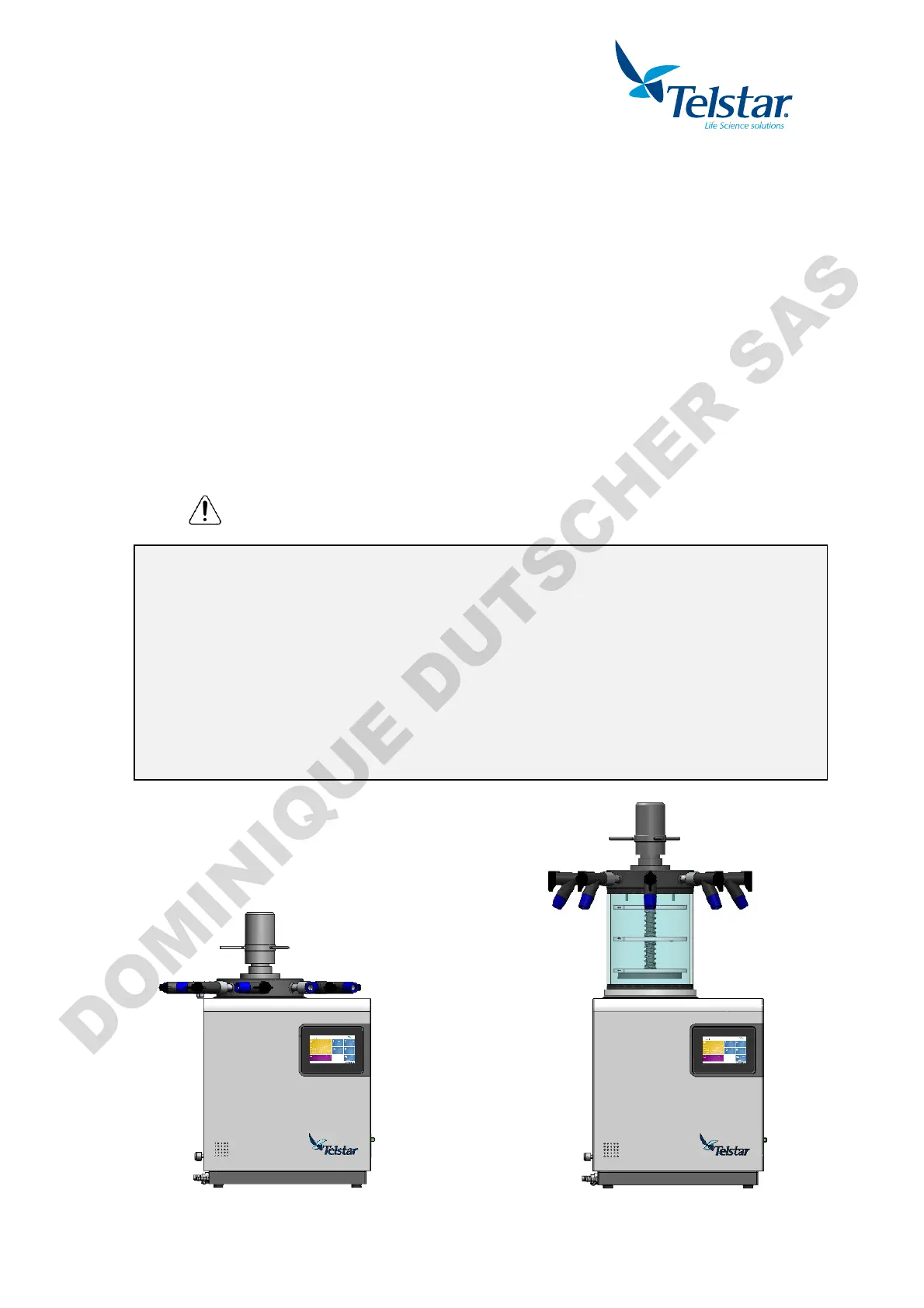

Inside the condenser (see Fig. A): It is advisable to load the product only on the

lower and middle plates. The higher plates do not receive cold as do the other plates

because the vacuum supply is placed at top of the condenser. The equipment allows

you to program recipes (see chapter 10.6) to run a complete cycle without making

any manual actions.

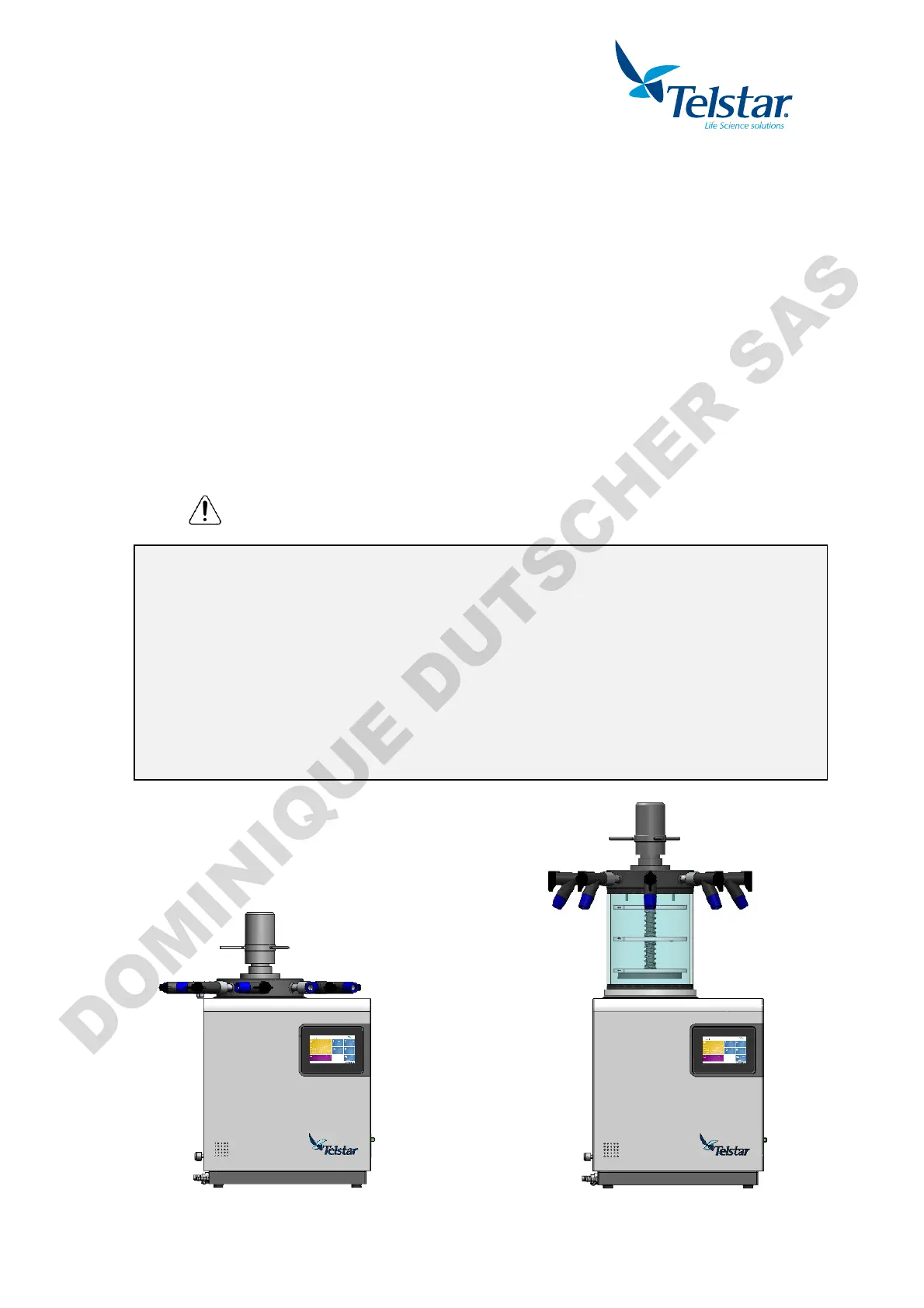

Outside the condenser: This is recommended when the quantity of product allows

you to load the three plates. It is advisable to freeze the product inside the

condenser because the heated plates will be cold and heating rates from negative

temperatures may be reached. Once the product is frozen, remove the plates of the

condenser and place them in the chamber (see Fig. B). Also, it is possible to load a

product that has been frozen in other equipment. The equipment allows you to

program recipes (see chapter 10.6) to run a complete cycle without making any

manual actions once the product is frozen and the chamber has been placed.

NOTE

Fig. A Fig. B

of the freeze-drying process depends for an important part from this height. It is very

advisable to load the freeze-dryer uniformly and that the height of product is the same in

all zones.

The time of the process also depends on:

-The heat provided to product (external if the manifold is used or by means of an

electrical resistor placed inside the plates).

-The maximum temperature accepted by the product.

-The final degree of humidity desired.

-The percentage of solid material in the product.

-The vacuum degree obtained.

-The total amount of product to be dried each time.

-The temperature of the condenser.

Loading...

Loading...