ATTACHMENTS

12D-7

SECTION 12D. MOWER AND REEL ADJUSTMENTS

DOWN PRESSURE ADJUSTMENT

Each reel is equipped with a down pressure spring.

Down pressure improves cutting quality by ensuring

good contact between the reel and ground when cut-

ting uneven surfaces. Check and adjust down pressure

any time the cutting height has been changed (see

Figure 12D-1)

1. Lower reels to the ground. Engage the parking

brake, stop engine, and remove the key from the

ignition switch.

NOTE:

Reels must be lowered when measuring down

pressure.

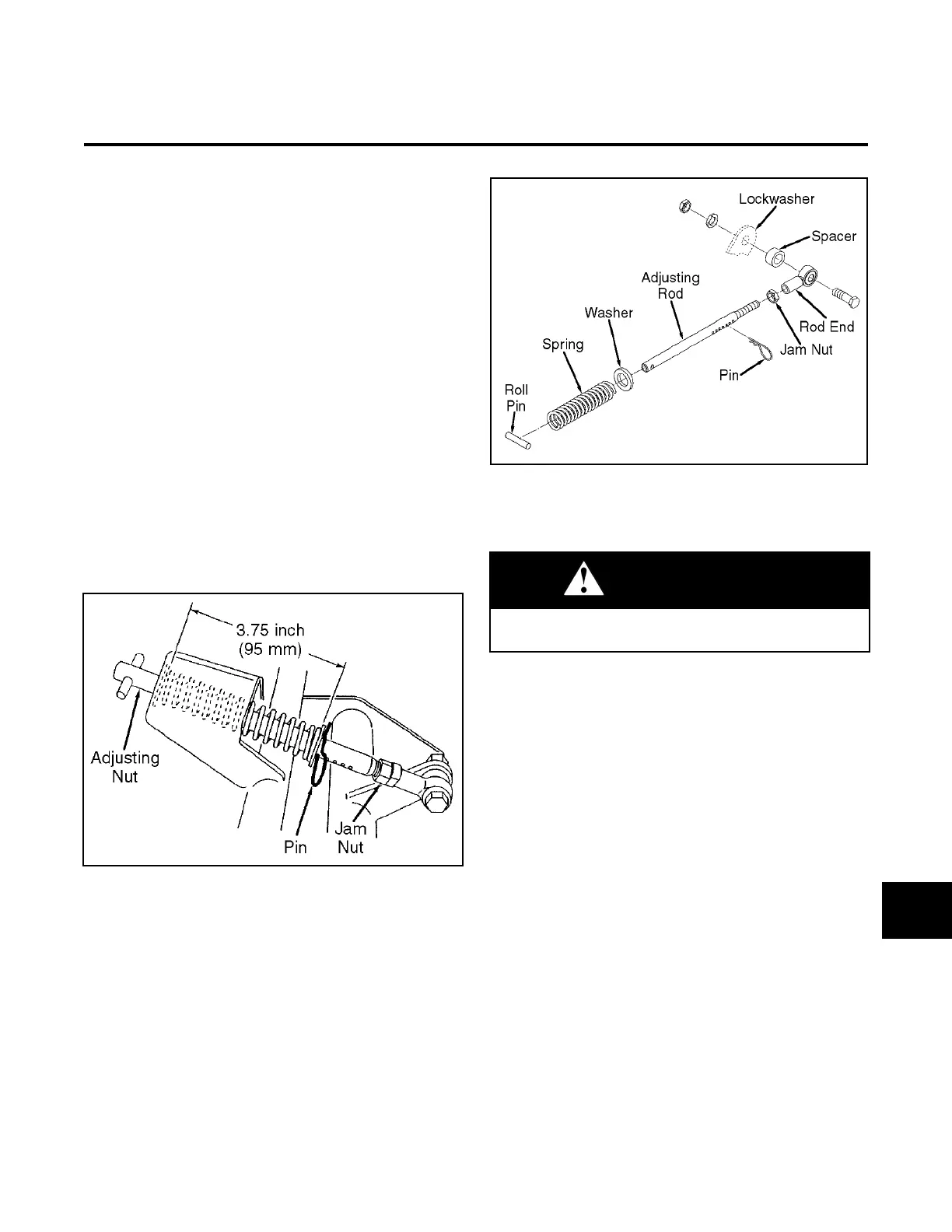

2. Measure the length of the spring as shown. Adjust

the spring to 3.75 ±0.06 in (95 ±1.5 mm).

To make fine adjustments, loosen the jam nut and

turn the adjusting rod in or out of the rod end.

Tighten the jam nut after the adjustment is made.

For adjustments greater than 0.25 in (6 mm), relax

spring tension by first raising the reels, then adjust

the pin.

Figure 12D-1. Down Pressure Adjustment

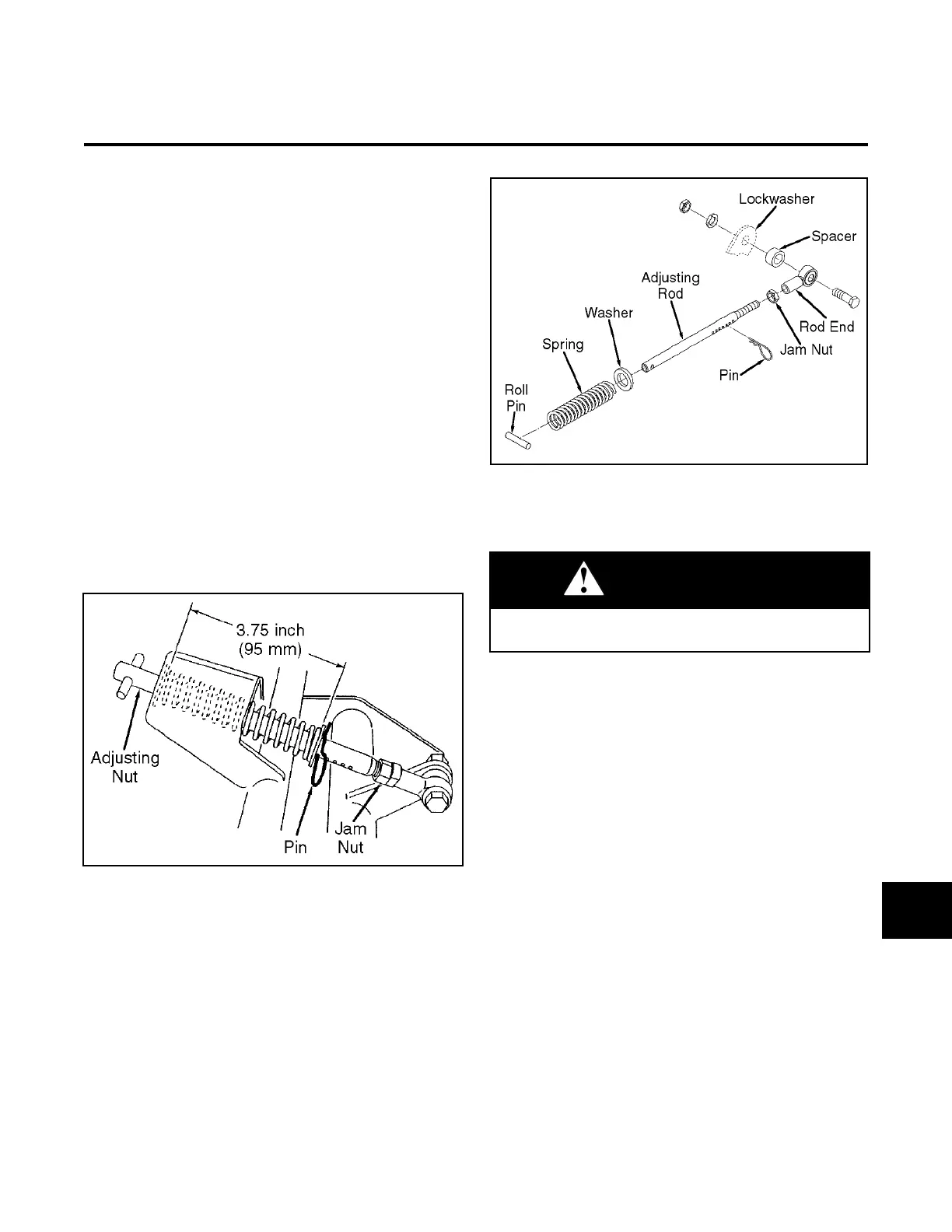

If the down pressure springs require replacement, dis-

assemble as shown in Figure 12D-2. Replace dam-

aged components, reassemble as shown and adjust as

described above.

Figure 12D-2. Down Pressure Springs Repair

BEDKNIFE-TO-REEL ADJUSTMENT

1. Reel bearings are self-adjusting. Check the reel

bearings for end play or radial play which would

indicate worn bearings. Replace bearings as

described in Section 12F.

2. Inspect the reel blades and bedknife to insure

good sharp edges without bends or nicks.

a. The leading edge of the reel blades must be

sharp, free of burrs, and show no signs of

rounding off.

b. The bedknife and bedknife backing must be

securely tightened. The bedknife must be

straight and sharp.

c. For the standard low profile bedknife, a flat sur-

face of at least 0.0625 in (1.5 mm) minimum

must be maintained on the front face of the

bedknife (see Figure 12D-3). Use a small disc

grinder to dress the bedknife.

WARNING

To prevent injury and damage to the cutting edges,

handle the reel with extreme care.

12D

Loading...

Loading...