ATTACHMENTS

12E-14

REEL REPAIR AND GRINDING

Reel blades and bedknife that are slightly dull or have

minor nicks or high spots can be reconditioned quickly

and easily by lapping. Grinding is required when more

severe wear or damage exists. If a wave has devel-

oped in the bedknife, lapping will not solve the problem

and the mower reel and bedknife must be ground or

replaced.

NOTE:

A reel worn or one incorrectly ground to a conical

shape instead of a cylindrical shape will cause a

wavy bedknife.

Prior to grinding the reel, clean, inspect, and repair the

reel as follows:

• Steam clean or wash the reel.

• Clean the reel thoroughly by scraping off all dried

material from the blades.

• Inspect the back of each reel blade for irregular

surface which could cause the guide finger to hang

while grinding. Remove any irregularities.

• Inspect the welds at the spiders. If any have cracked

or broken loose, reweld using a #7018 low hydrogen

welding rod.

• Straighten any bent reel blades by hammering into

shape with a block of steel and a hammer.

The method of grinding will depend upon the grinding

equipment being used (Figure 12E-5). Set up and

operate the grinding machine in accordance with the

manufacturer’s instructions.

Figure 12E-5. Reel Grinding Procedure

1. Before mounting the bedknife on the grinding

machine, thoroughly remove all dried material,

rust, and scale from the bedknife.

2. Hand held grinders can be used to grind the bed-

knife while it is installed in the mower unit. Other

grinding machines require the removal of the bed-

knife from the mower. Refer to the grinding

machine manufacturer’s instructions for mounting

the bedknife and operating the grinder.

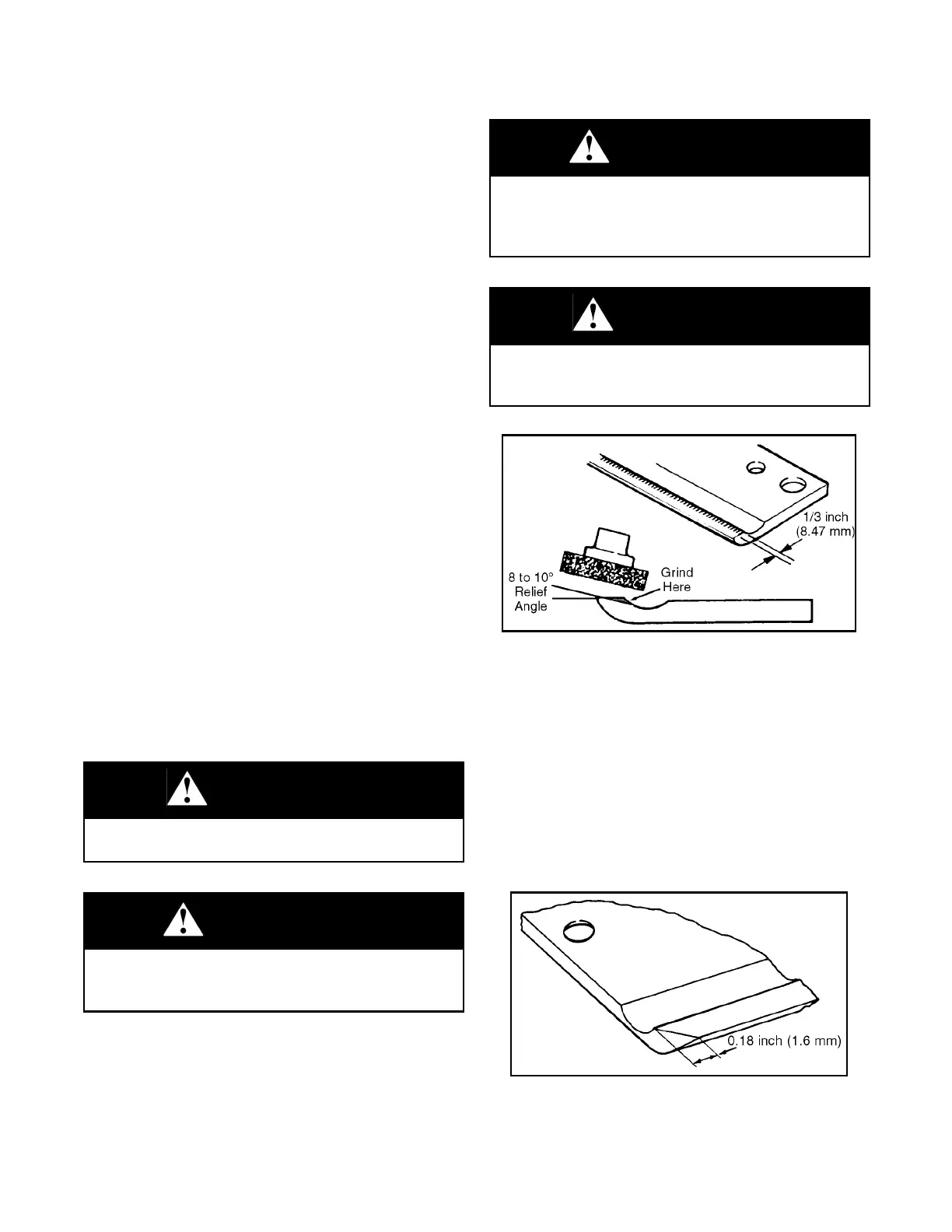

3. Tilt the grinding head so the stone contacts the

bedknife at the rear one third of the top surface.

This will give proper set up to grind the bedknife

correctly (Figure 12E-6).

Figure 12E-6. Bedknife Grinding Angle

DANGER

Always wear eye protection when operating a grind-

ing machine.

CAUTION

Handle and store grinding wheels carefully. Discard

grinding wheels that are cracked, badly chipped, or

have been dropped.

CAUTION

Always install blotter washers between the grinding

wheel and the flanges. Do not overtighten the flange

nut on the grinding wheel. Do not run a grinding

wheel faster than specified on the wheel blotters.

DANGER

Do not stand in line with a grinding wheel the first

three minutes it is run. Never jam a grinding wheel

into the work piece.

Loading...

Loading...