STEERING

6C-6

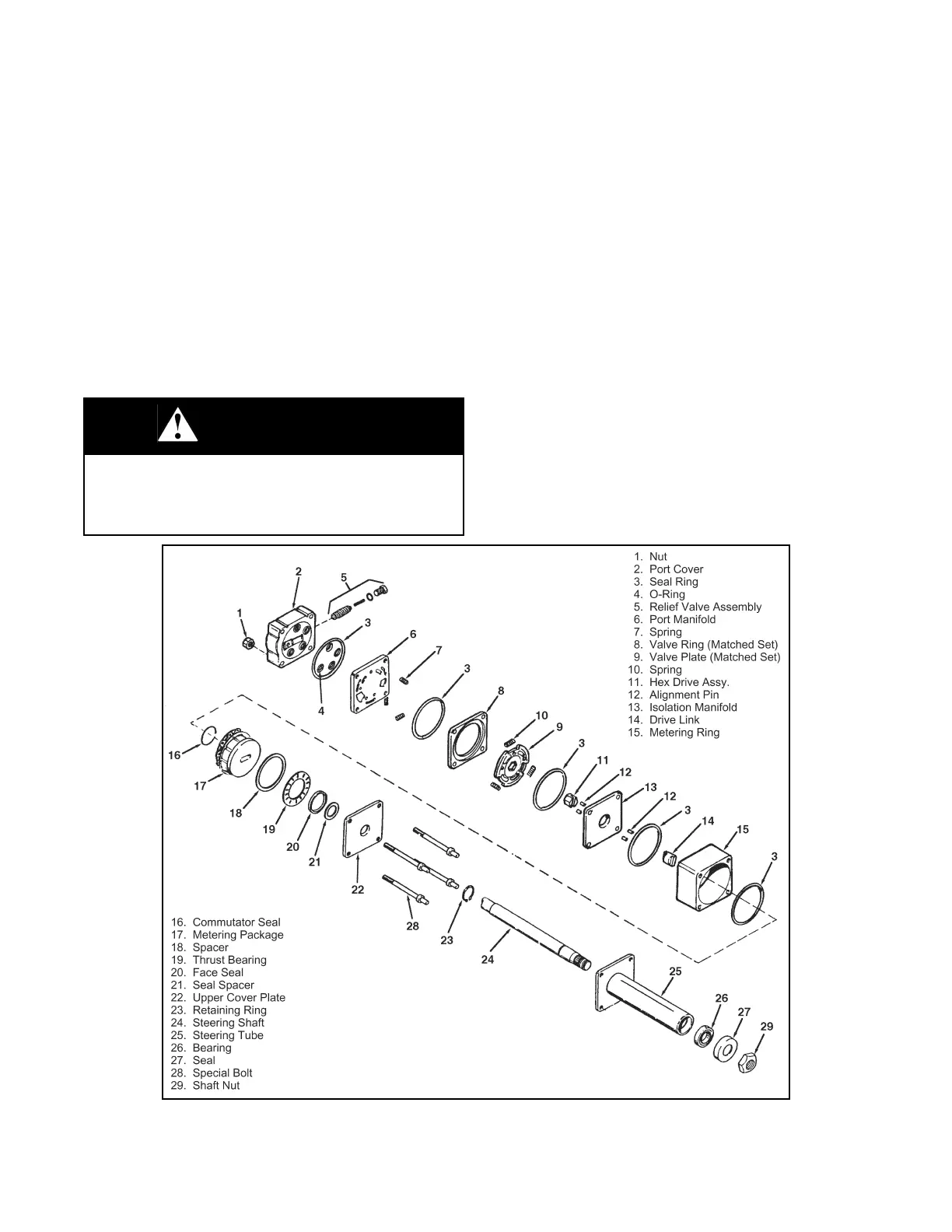

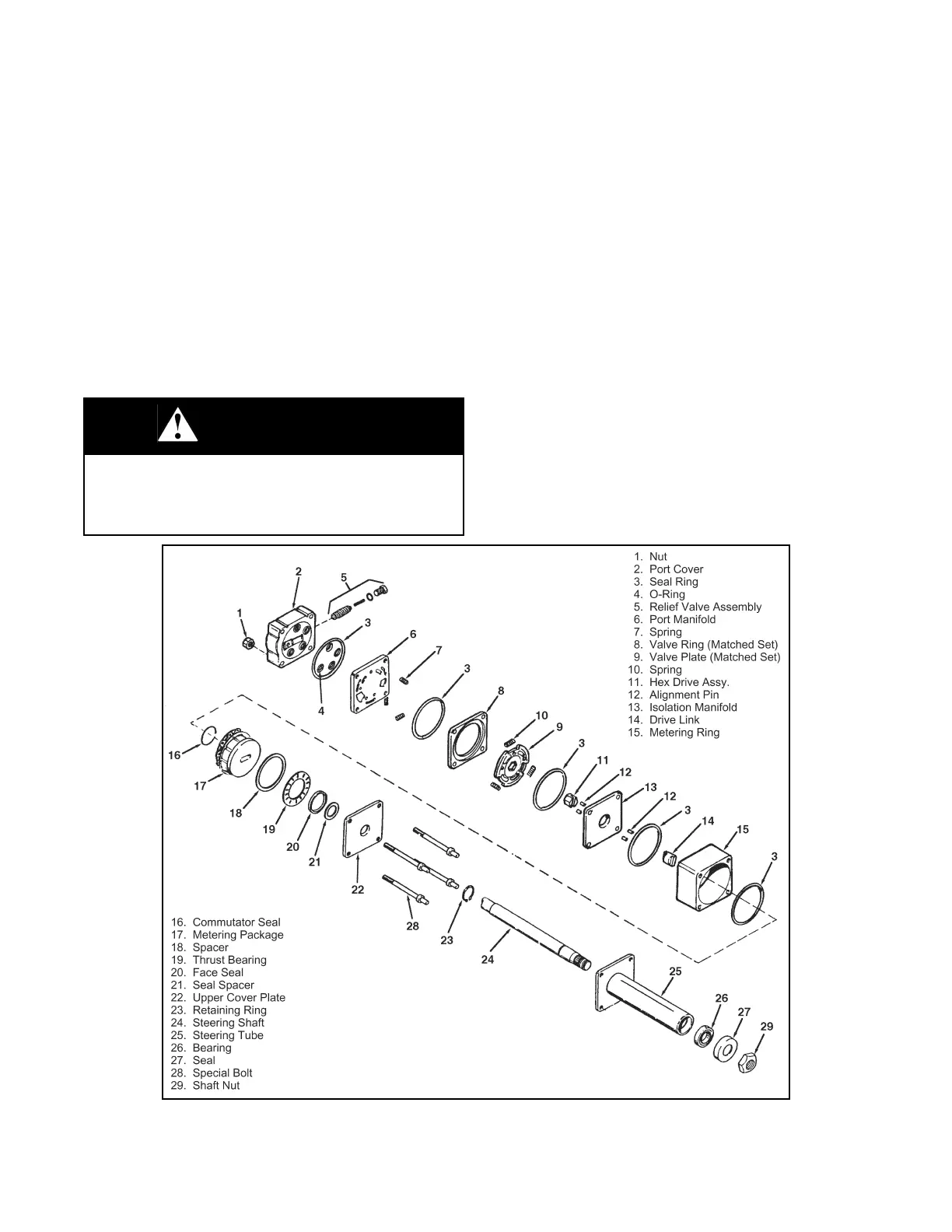

STEERING VALVE DISASSEMBLY

NOTE:

Before attempting repairs or disassembly of any

hydraulic components, thoroughly clean the com-

ponents and work area. A clean work area is

essential to satisfactory operation of repaired

hydraulic components.

NOTE:

Scribe a line from the top to the bottom of the

steering valve assembly not including the steering

tube. A scribed line can be used for reference dur-

ing assembly for proper assembly of valve sec-

tions.

1. Place the power steering service fixture

(Figure 6A-1) securely in a vise.

2. Remove the nuts (1) and cover (2), see

Figure 6C-2.

3. Remove the nine needle rollers (5), see

Figure 6C-2.

4. Carefully remove the port manifold (6). Be pre-

pared to catch the three springs (7). Remove the

springs (Figure 6C-2.).

5. Remove the valve ring (8), valve plate springs

(10), and valve plate (9), see Figure 6C-2.

6. Remove the hex drive (11) and isolation manifold

(13), see Figure 6C-2.

NOTE:

Secure the alignments pins (12) to prevent loss,

see Figure 6C-2.

7. Remove the drive link (14) and metering ring (15),

see Figure 6C-2.

8. Remove the metering package (17) and commu-

tator seal (16), see Figure 6C-2. The metering

package is serviced as an assembly kit. Refer to

the parts manual.

Figure 6C-2. Steering Unit Exploded View

WARNING

Wear eye protection when assembling and disas-

sembling the steering valve. Springs and other

objects may be propelled into the air causing eye

injury.

Loading...

Loading...