HYDRAULICS

8C-6

37° FLARE FITTINGS

Torque Recommendations

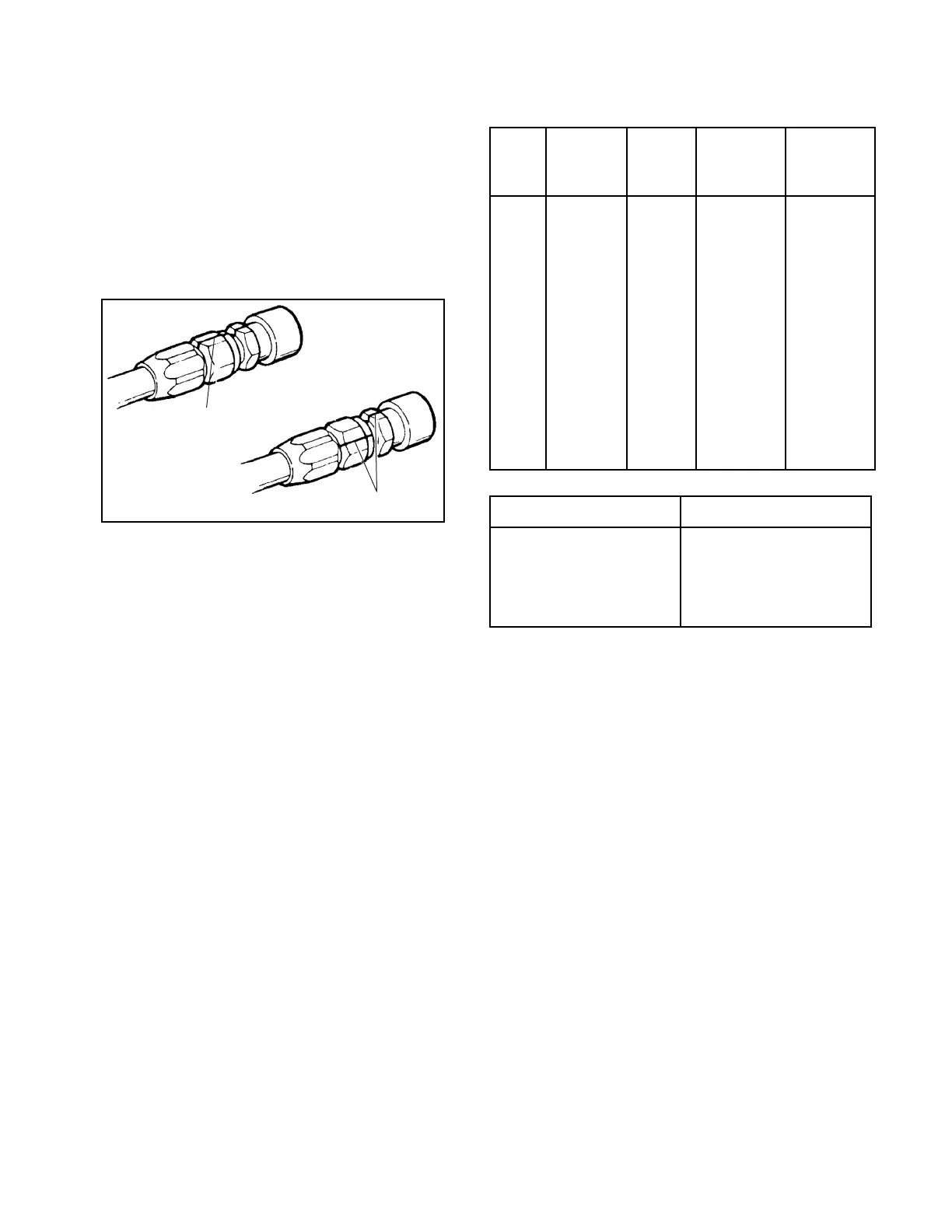

1. Assemble tube nut adapter to fitting with a mini-

mum torque (finger tight) until the flare contact the

seat on the fitting body.

2. For tightening reference mark a line lengthwise on

the flats of both the nut and adapter fitting with a

marker shown in Figure 8C-1.

Figure 8C-1. Reference Marking

3. Using a wrench, tighten the nut the amount shown

in the table below. The line will show which fittings

have been tightened correctly and also indicates if

a fitting is becoming loose.

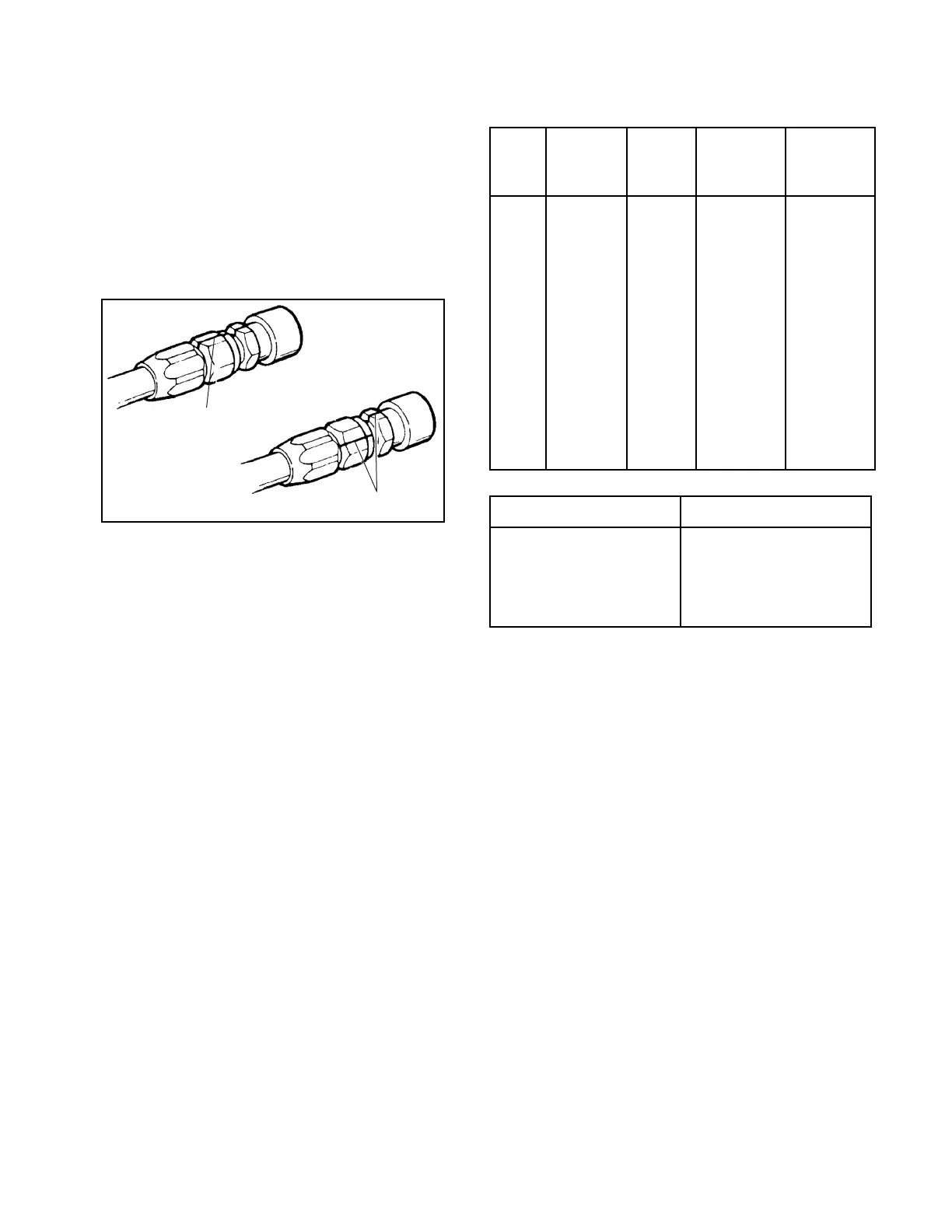

Table 8C-1: 37° Flare Torque Recommendations

HOSE INSTALLATION

INSTRUCTIONS

1. Hold the fixed portion of the hose coupling with

one wrench; use a second wrench to tighten or

loosen the hose nut. This will avoid damaging the

fitting seal. When tightening a hose, do not permit

it to twist; hold it in a normal straight position.

2. When installing mower hoses, place the fittings at

angles to avoid contact with fixed parts when turn-

ing. Make sure hoses are assembled to proper “A”

and “B” ports on components.

Assemble Finger Tight

and Mark as Shown.

Tighten per Chart

SAE

Dash

Size

Thread

Size

Tube

O.D.

Torque In-

lbs

# of Flat

Rotations

3 3/8-24 0.188 95-105 1 1/2:1 3/4

4 7/16-20 0.250 135-145 2 1/4:2 3/4

5 1/2-20 0.312 170-190 3 1/4:3 3/4

6 9/16-18 0.375 215-245 2 1/4:2 3/4

8 3/4-16 0.500 430-470 2 1/4:2 3/4

10 7/8-14 0.625 680-750 2:2 1/2

12 1 1/16-12 0.750 950-1050 2:2 1/2

14 1 3/8-12 0.875 1000-1100 1:1 1/2

16 1 5/16-12 1.000 1300-1360 2 1/4:2 3/4

20 1 5/8-12 1.250 1520-1600 1 1/4:1 3/4

24 1 7/8-12 1.500 1900-2000 3/4:1 1/4

Tube O.D or Hose I.D. Rotate No. of Hex Flats

3/8” 2

1/2” 2

5/8” 1 1/2-2

1” 3/4-1

Loading...

Loading...