5

5-9

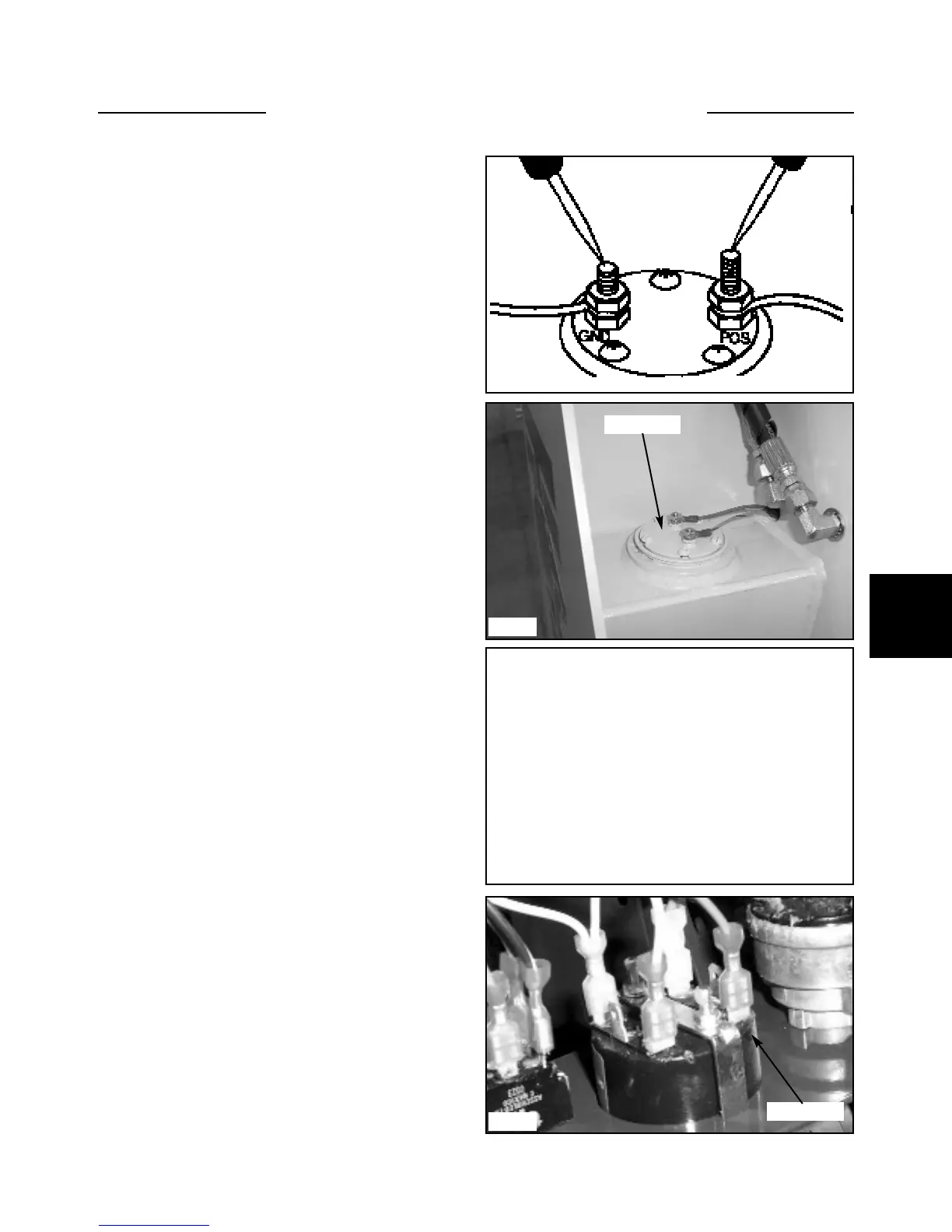

1 With the ignition switch off, connect an ohmmeter

between the positive and negative terminals of the fuel

sending unit. (fig. C306)

2 An ohmmeter reading of 50 to 500 is normal. A read-

ing higher or lower means a faulty sender and will need

replaced.

Testing the Fuel Sender

Replacement

1 Remove any attachment, raise the boom arms and

engage the boom support pins. Shut off the engine and

engage the parking brake.

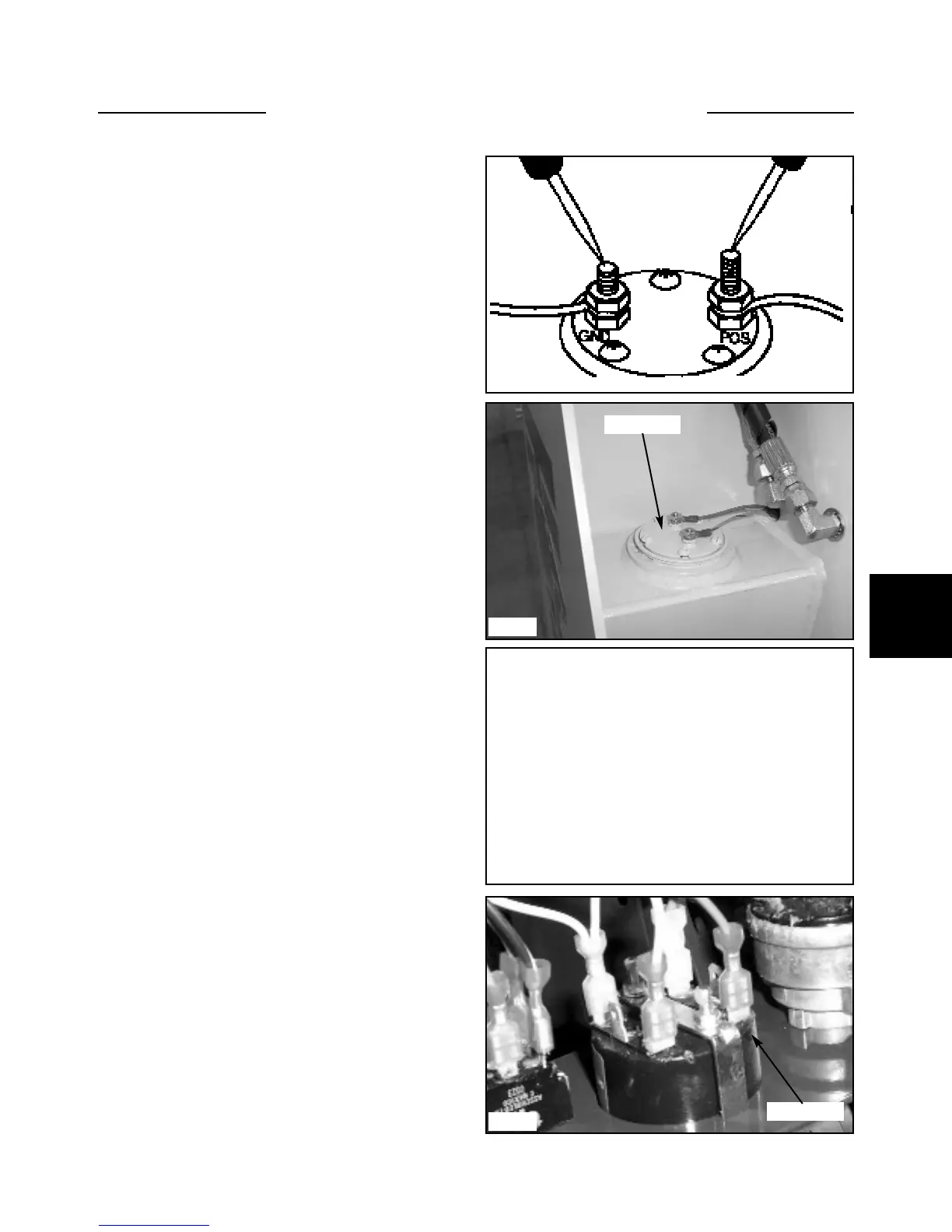

2 Remove the 2 wires connected to the fuel sending

unit. The fuel sender is located just below the lift cylin-

der, right hand side, on the fuel tank. (fig. C5089)

3 Remove the 5 screws retaining the sender to the fuel

tank.

4 Remove the sending unit and discard the gasket.

5 Install a new sending unit and gasket. Use gasket

sealant on both sides of the gasket.

6 Use thread sealant on the screws and torque the

screws to 20 inch lbs.

7 Connect the sender wires taking care not to over

tighten the nuts and stripping the studs. Green wire is

ground.

Testing the Fuel

Sender/Hour Meter

LB002500 Onward

The hour meter records the number of engine operating

hours.

LB002500 Onward

1 To check the fuel sender, remove the dash panel.

2 Withe the ignition switch off, connect an ohmmeter

between the #1 and the #3 terminals.

3 An ohmmeter reading of 150 to 200ohms is normal.

A higher or lower reading means the gauge is faulty and

needs to be replaced.

NOTE: If the fuel gauge test results were good and the

gauge still fails to function, do the following test.

1 With the ignition switch off, connect an ohmmeter

between the #1 terminal and the other end to ground.

2 An ohmmeter reading of 50 to 500 ohms is normal.

A higher or lower reading means the wire going to the #1

terminal is faulty.

NOTE: If test is good, check the fuel level sender.

INSTRUMENTATION 5.3

C5089

C5091

C5090

Sender unit

C306

Hour meter

Loading...

Loading...