5

5-18

SAFETY CIRCUIT 5.10

General Information

The loader is equipped with 3 inter - connected safety

switches. These switches operate 2 electric solenoid con-

trolled lock devices and a starter interlock system. One

(1) pair of solenoid coils on the hydraulic control valve .

The operation of the solenoid coils and loader functions

will be prevented if one of these safety switches are

open. For proper operation of the solenoid coils and

loader functions, all 3 must be hooked up, functioning

and, if applicable, adjusted correctly. There is also a

switch that controls the dash panel brake warning light.

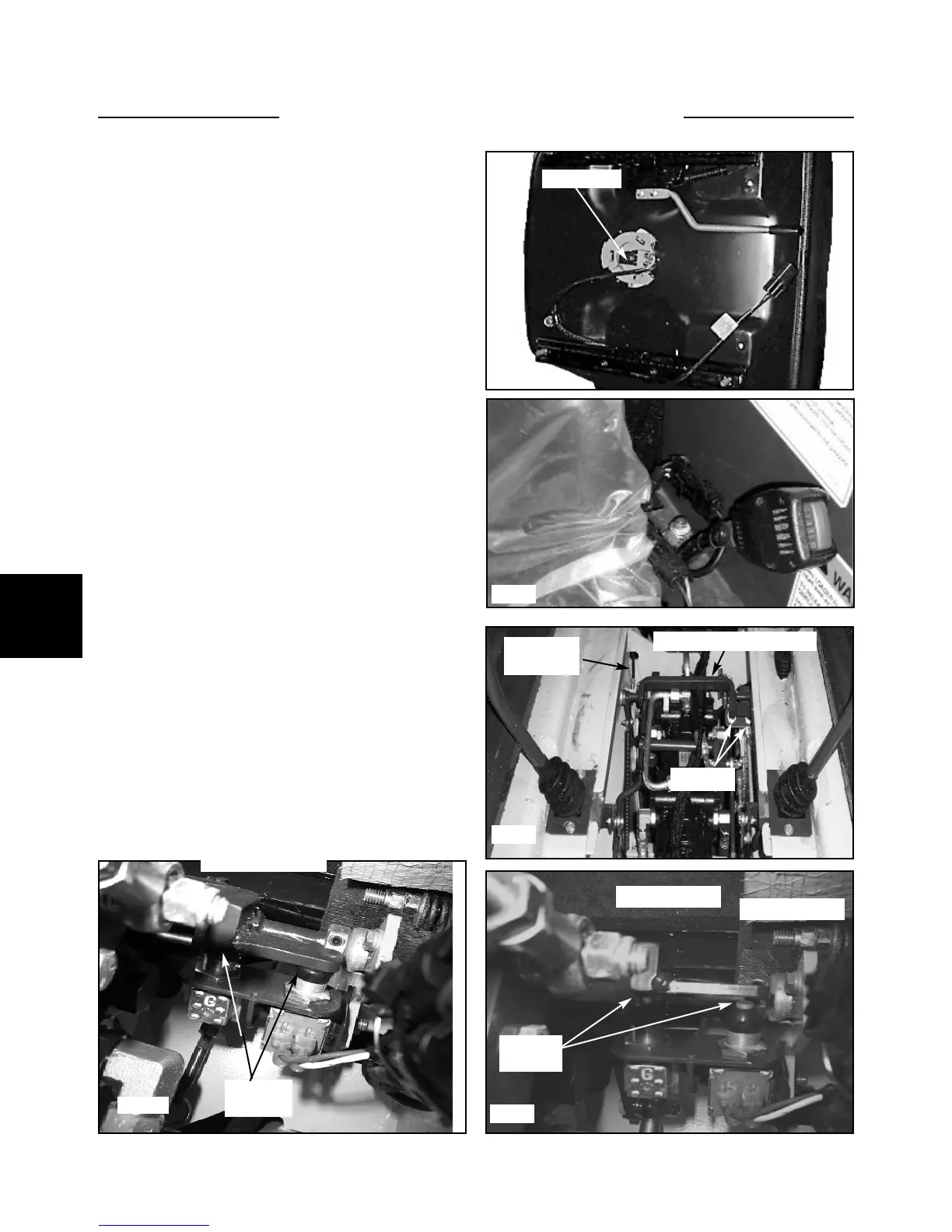

The bottom of the operators seat is equipped with a pres-

sure sensitive switch.(fig. C807) The operator must be in

the seat to close the switch and release the parking brake

and unlock the control valve functions. No adjustments

required. When removing and replacing the seat, be sure

not to pinch the wires under the seat plate.

The seat belt assembly is equipped with a safety switch.

The operator must have the seat belt fastened around

them in order to close the switch and allow the parking

brake to release and the control valve to function. (fig.

C5020) No adjustments required.

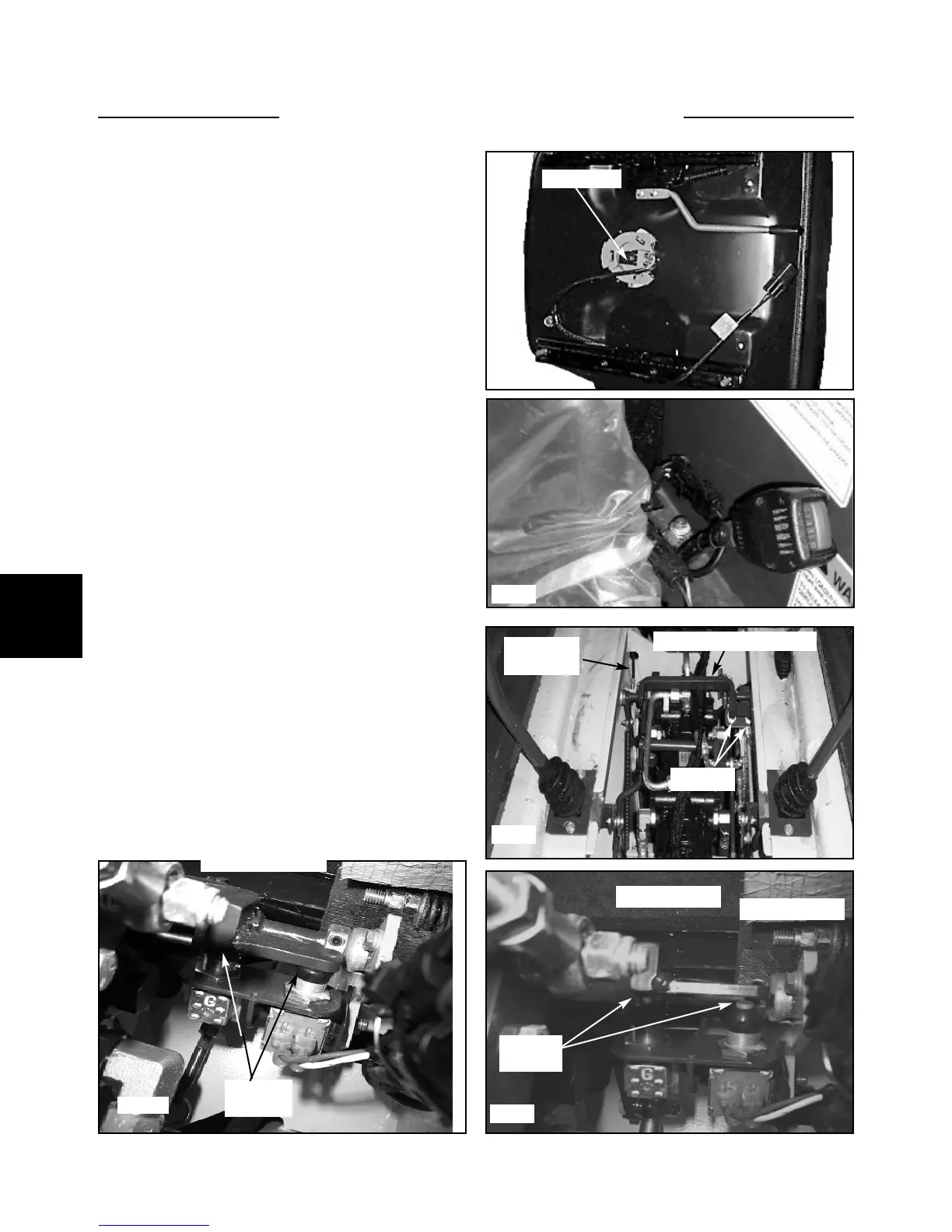

The restraint bar controls two safety switches (fig.

C5628) located under the operators seat assembly. With

the restraint bar in the raised position, the parking brake

is activated, the control valve functions are locked and the

activation indicator lights are illuminated on the dash

panel. (fig C5629)

Lowering the restraint bar releases the parking brake,

turns off the indicator lights in the dash panel and releas-

es the locks in the control valve. (fig. C5630)

The restraint bar must be in the lowered position for the

control functions to operate.

C5020

C807

Seat switch

C5629

C5628

Brake pull off assembly

Restraint

bar cable

Safety switches

C5630

Restraint bar up

Switches

open

Restraint bar down

Switches

closed

Switches

Loading...

Loading...