7-17

7

C5642

Installation

14 Using a hoist, set the engine into the loader through

the rear door opening.. (fig. C2214) Have a helper

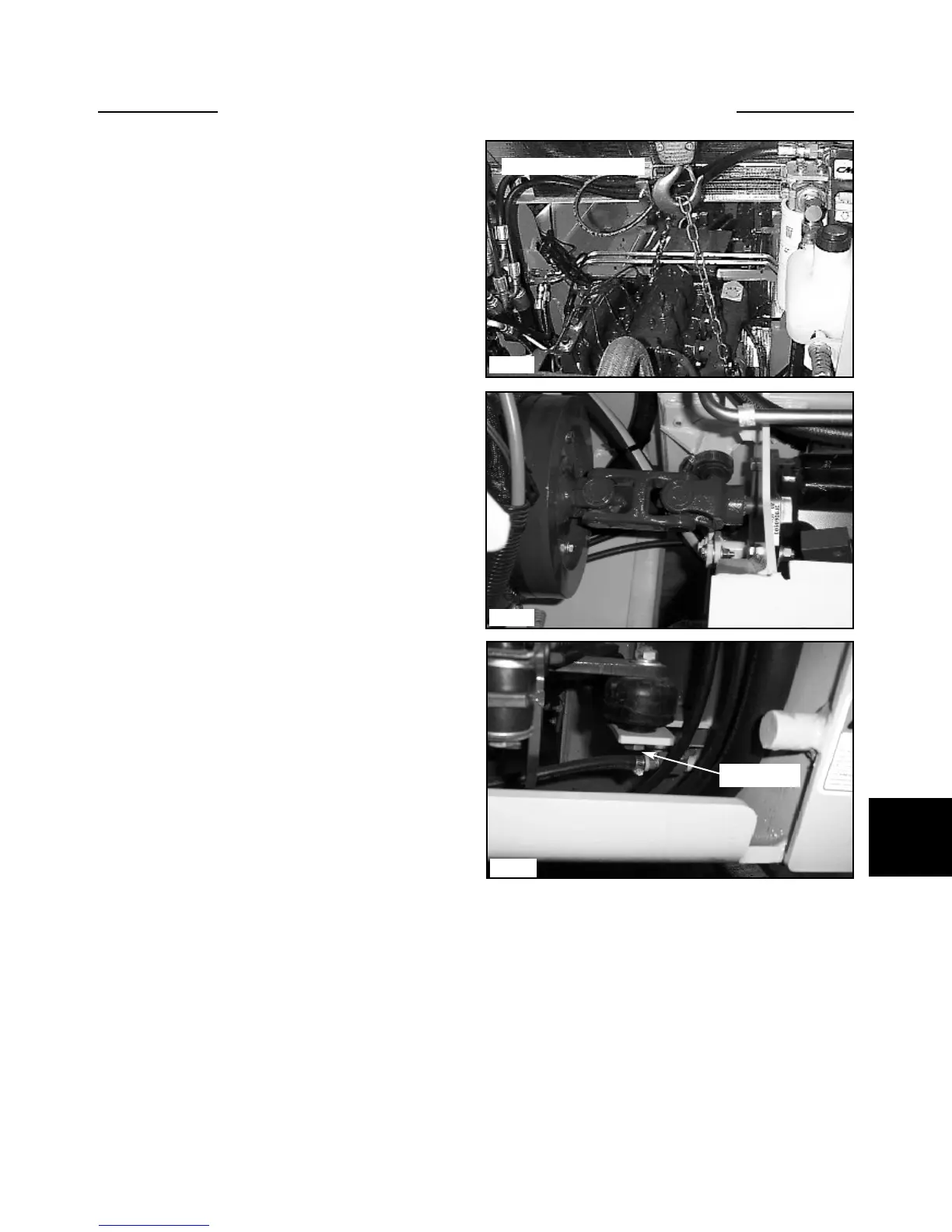

inside the cab to line up the engine U- Joint to the

hydrostatic pump input shaft. (fig. C5211) Align the

engine U-Joint in a straight line with the hydrostatic

pump. Failure to align the U- Joint properly will cause

premature U- Joint failure.

15 Install the bottom nuts to the isolators. Torque the

nuts to 35 ft lbs. (47.5 Nm).(fig. C5642) Recheck the

alignment of the u-joint once the engine is torqued into

place. Re-adjust the engine position if required to main-

tain proper u-joint alignement.

16 Connect the various electrical connections, routing

wires carefully to prevent chaffing. Tie the wires with

zip ties as required. Be sure all ground points are clean.

17 Connect the throttle rod to the throttle swivel.

(Adjustment- Section 4.4)

18 Install the intake and exhaust systems.

18 Bolt the fuel filter to the frame and connect the

fuel hoses.

19 Connect the fuel supply and turn on the fuel tank

petcock.

20 Bleed the air from the fuel lines.(section 7.1)

20 Check the engine oil and coolant level.

21 Check again for any loose wires that may be dan-

gling free.

22 Test fire the engine.

ENGINE REPLACEMENT 7.3

C5211

C2214

Not exactly as shown

Bottom nut

Loading...

Loading...