7-16

7

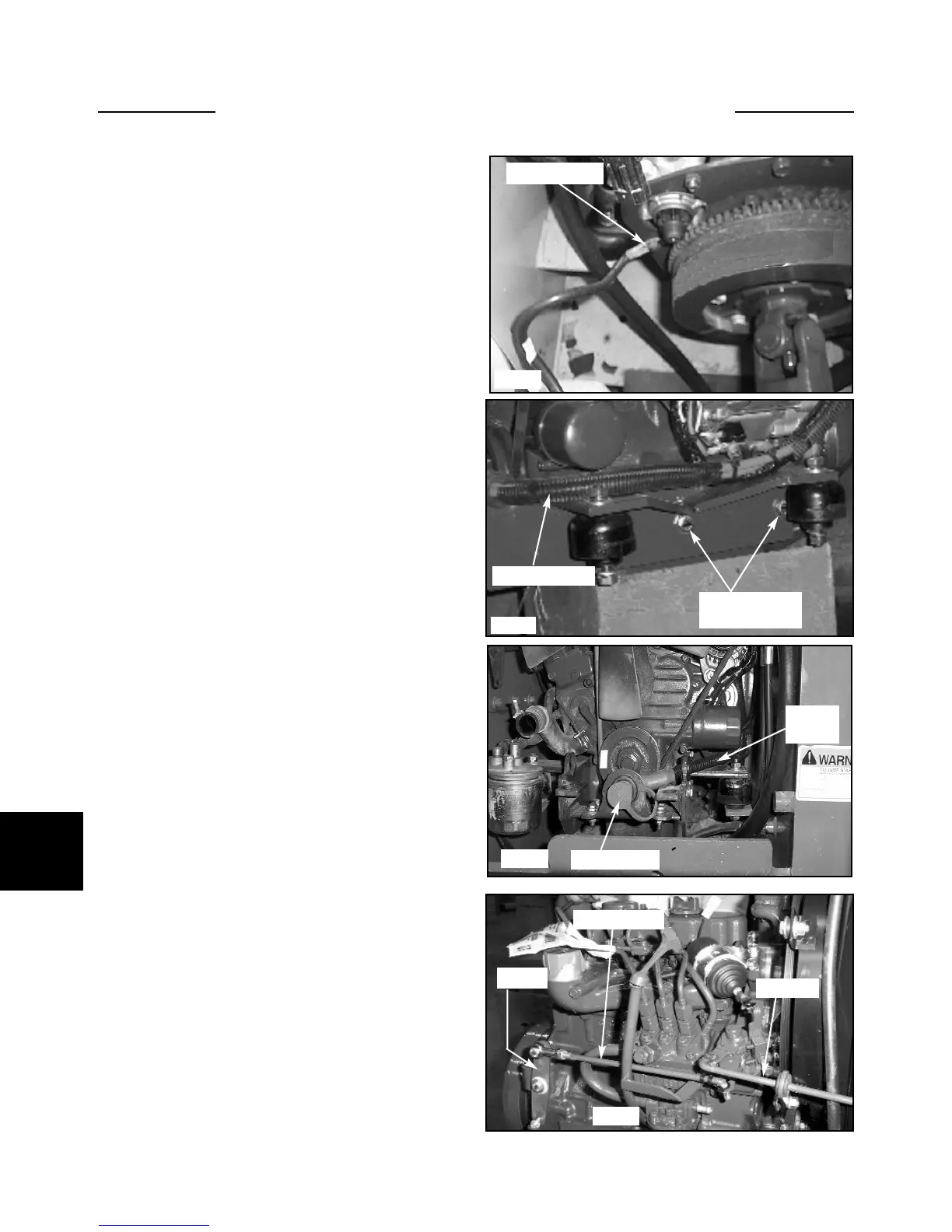

C5162

C5085

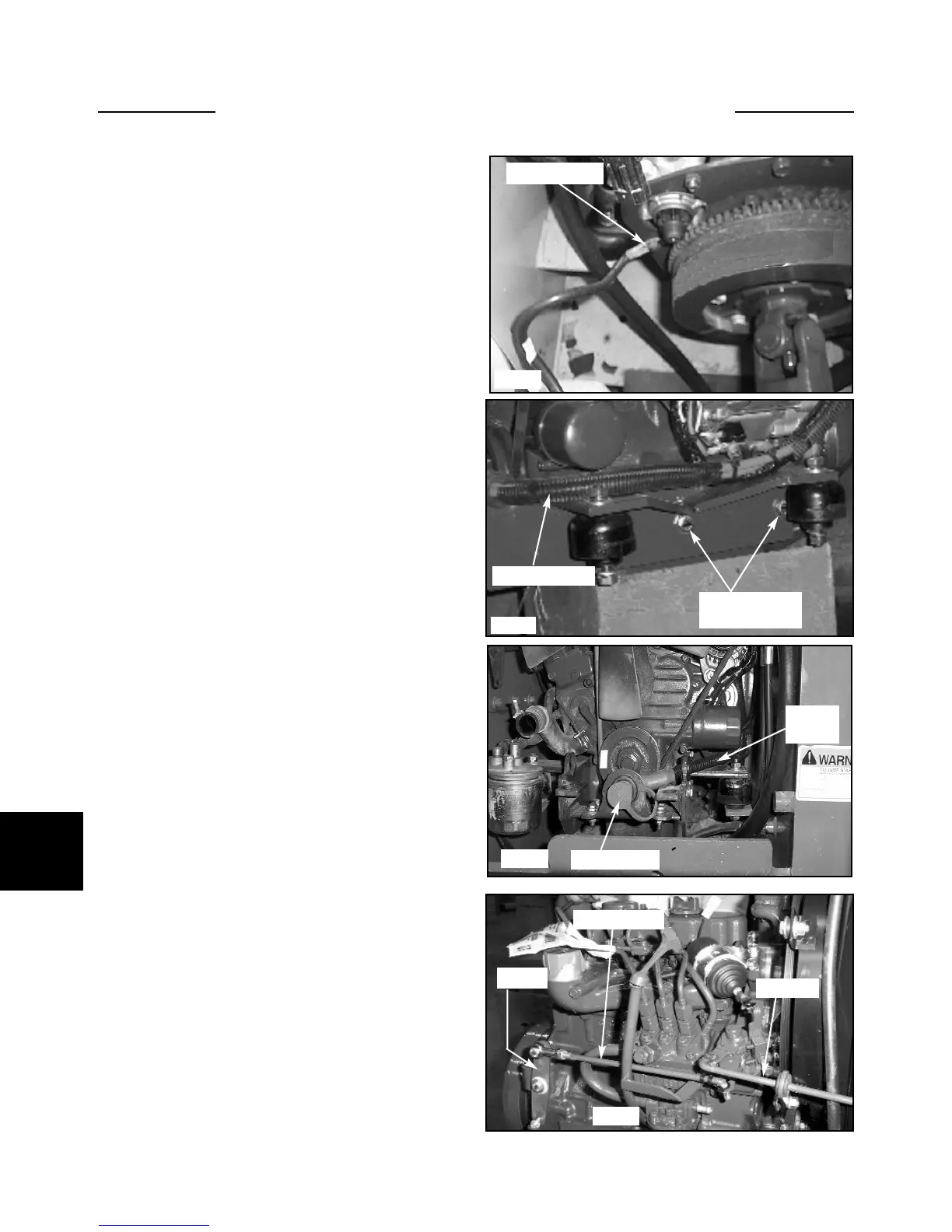

C5655

Installation

If the engine is being replaced with a new assembly, the

engine will require some preparation.

1 Remove the protective rust preventative coating from

the flywheel. Use a solvent to remove. The flywheel must

be clean with no nicks or burrs.

2 Install the engine U- Joint adapter. There are 5 bolts

hodling the adapter to the engine flywheel. Torque the

adapter bolts 20 ft lbs. (27.2 Nm)

3 Paint must be removed from the starter mount plate

where the engine ground strap is attach to the bottom

starter bolt. This will provide proper grounding of the

engine with the loader chassis. (fig. C5655)

4 Install the engine mounts. Apply Loctite 242 (blue)

to the threads of the mounting bolts. Torque the mounting

bolts to 35 ft lbs. (47.5 Nm). (fig. 5121)

5 Install the isolators into the engine mounts. (fig.

5121) Make sure the isolators are not separating or the

rubber is not deteriorated in any way. Replace isolators

as required.

6 Install the boosting lug mount and the boosting lug.

7 Install the engine temperature sender.

8 Install the engine wire harness and the positve battery

cable to the starter motor and the boosting lug.(fig.

C5162, fig. C5121)

9 Install the radiator to the engine mounts and install

the radiator hoses.

10 Install the fan guard to the radiator shroud.

11 Install the upper radiator mounting

bracket.(LB003382 Onward)

12 Add engine oil and coolant.

13 Install the engine throttle rod and the swivel to the

engine. Install the manual stop rod.(fig. C5085)

ENGINE REPLACEMENT 7.3

C5121

Ground cable

Engine mount

bolts

Swivel

Throttle rod

Stop rod

Positive cable

Positive

cable

Boosting lug

Loading...

Loading...