1

1-24

CONTROL VALVE 1.3

Disassembly / Repair 85 (con’t)

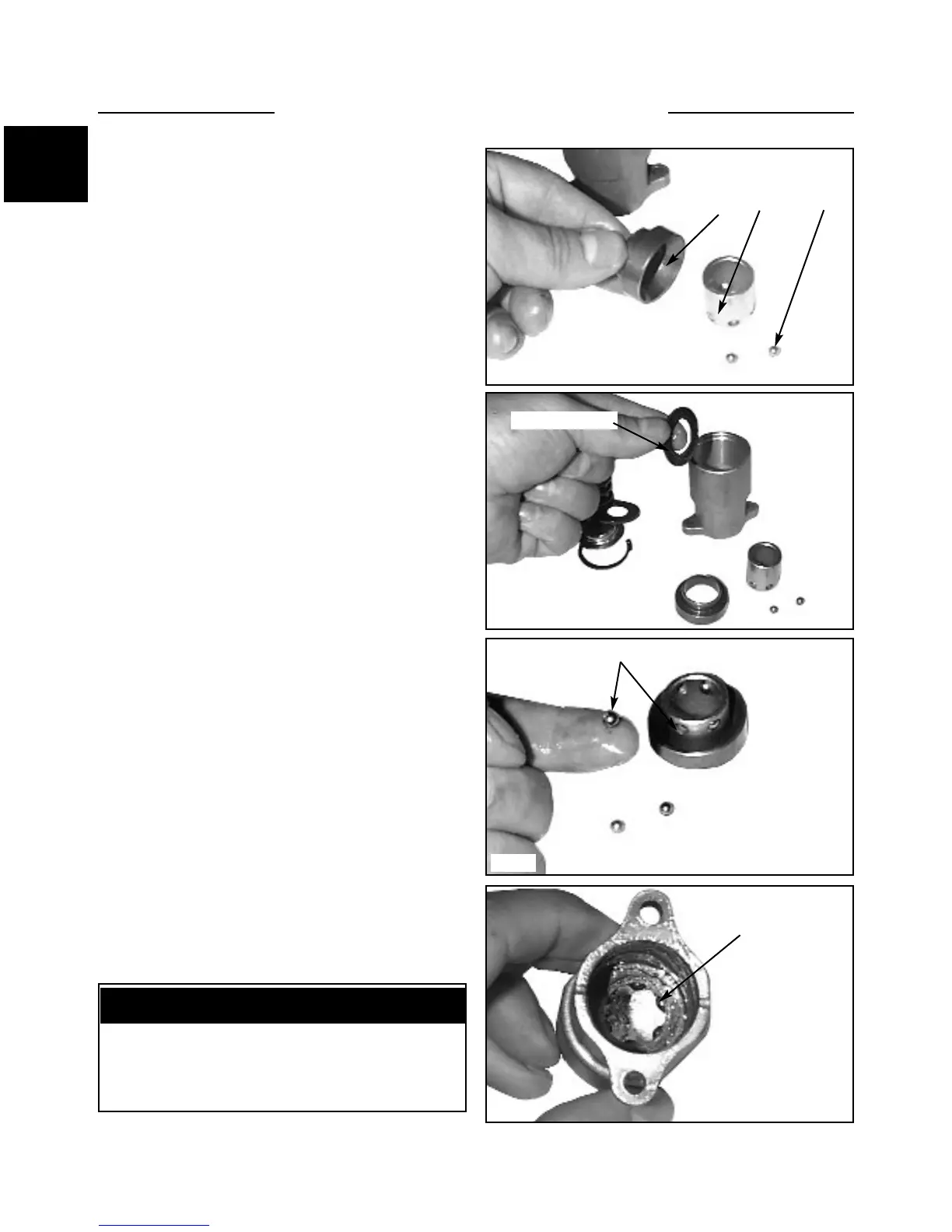

35. Separate the sleeve and cup assembly. (fig. C2409).

Inspect the tapered cup, balls and sleeve for wear.

Replace with new detent kit assembly if wear is evident.

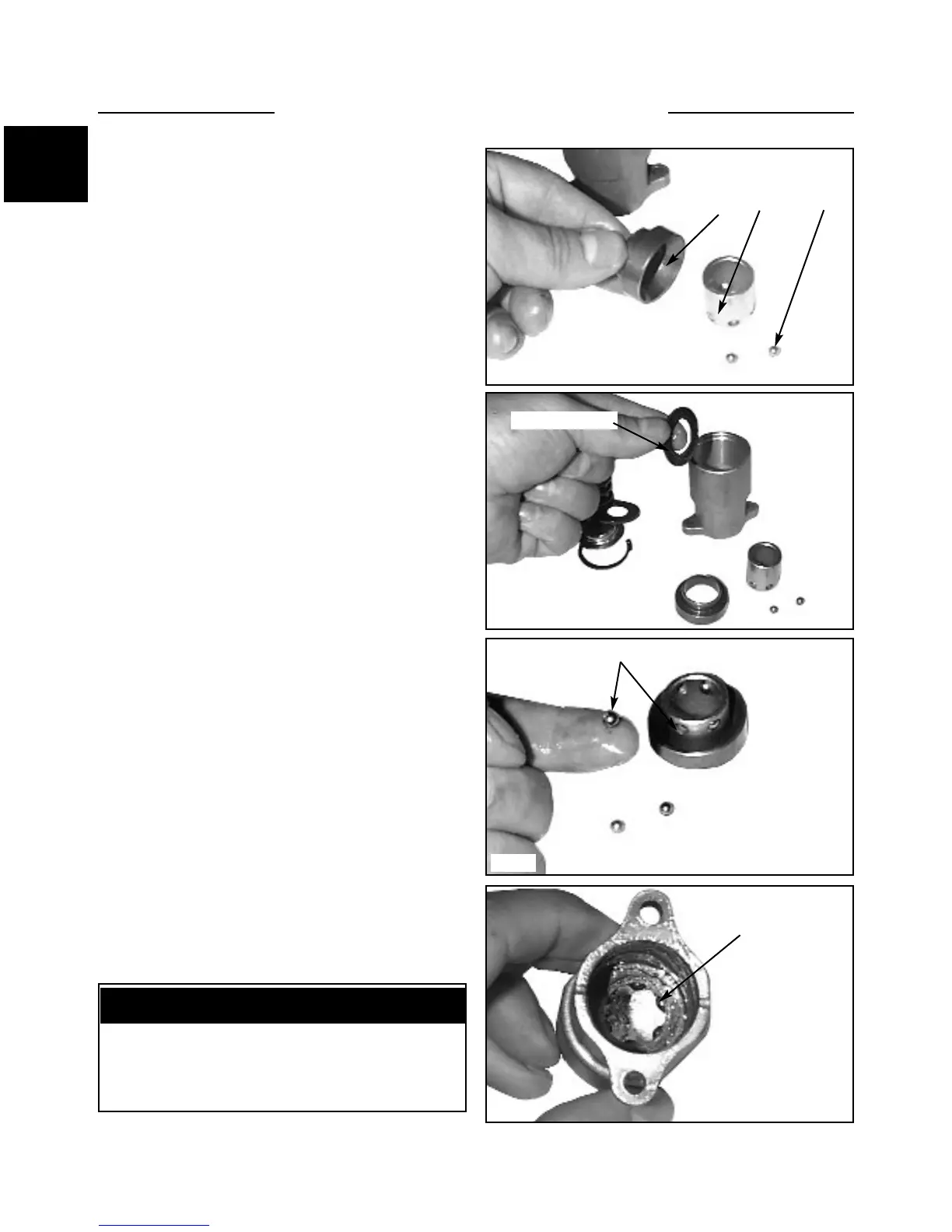

36. Remove the spring washer. (fig. C2410).

37. Clean all parts with solvent. Lubricate all parts with

Castrol Spheerol grease or equivalent.

38. Replace the greased detent balls to the cup and sleeve

(fig. C2411) and reassemble the complete spring return

mechanism in the reverse order above.

C2409

C2410

C2411

C2412

39. The grease holds the detent balls in position during

assembly to the control valve and spool. (fig. C2412)

40. Replace the cap assembly to the control valve and

tighten the screws evenly.(seal circlip wdith silicone)

Inspect cup, sleeve and balls

Remove washer

Grease detent and balls

Detent balls in

position

C heck and make sure the detent balls are in position

before assembling to the control valve to assure

proper function of the control spool and detent

mechanism.

IMPORTANT

Loading...

Loading...