2

2-8

1 Check oil level in reservoir:

a .fill to proper level as marked on site tube.

2 Inspect external control linkage for:

a. misadjustment or disconnection

b. binding, bending or breakage

c. misadjusted, damaged or broken hydroback

3 Inspect servo control valve for: ( if used )

a. proper inlet pressure

b. misadjusted or damaged neutral return spring

c. galled or stuck control spool

d. galled or stuck servo piston

4 Inspect heat exchanger for: (if used)

a. obstructed air flow

b. improper plumbing ( inlet to outlet )

c. obstructed fluid flow

5 Inspect inlet filter or screen for:

a. plugged or clogged screen or filter

b. obstructed inlet or outlet

c. open inlet to charge pump ( open line )

6 Check charge pressure:

a. follow test procedures section 2.5

7 Inspect charge relief valve for:

a. poppet held off seat

b. damaged or broken spring

c. damaged valve seat

d. improper charge relief setting

8 Inspect gear pump for:

a. broken or missing drive coupling

b. damaged or missing o-rings

c. galled or broken gear set

9 Inspect system relief valves for:

a. damaged or broken springs

b. valve held of seat

c. damaged valve seat

d. improper pressure relief settings

10 Check system pressure:

a. follow test procedures section 2.5

11 Inspect hydraulic motor for:

a. disconnected coupling

TROUBLE SHOOTING 2.4

System Diagnosing Steps And Special Tools

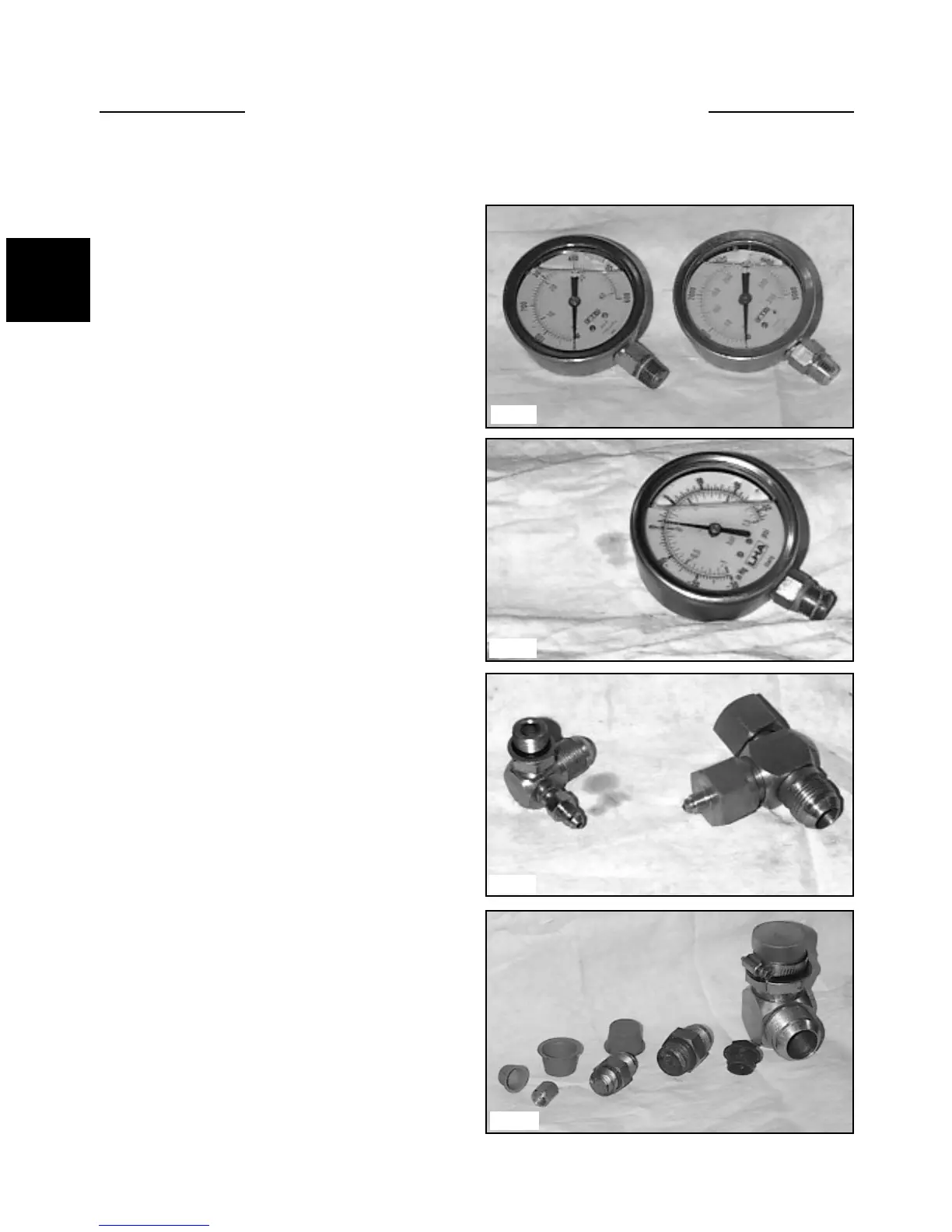

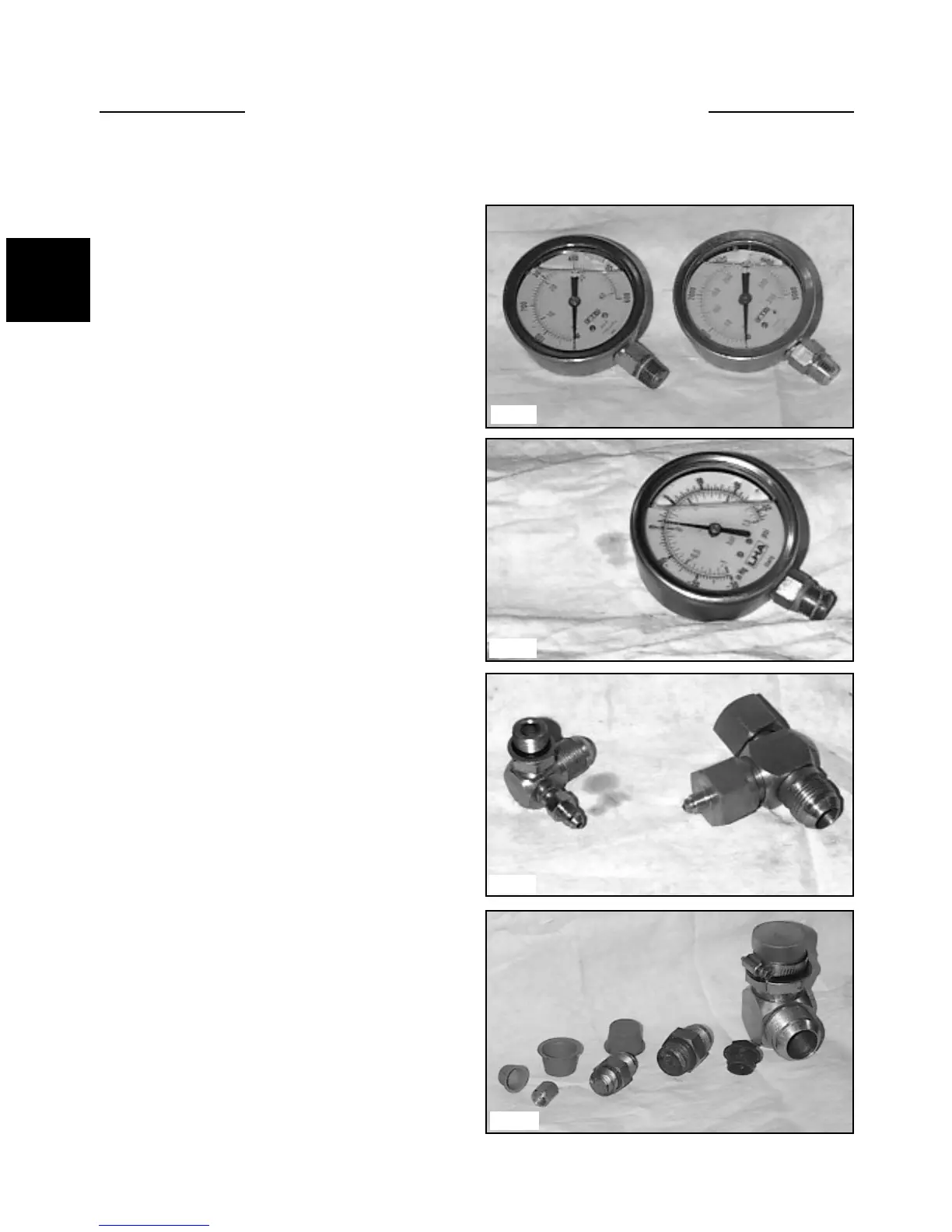

Photographs in the right hand column show some of the

special tools that may be required to diagnose and repair

the hydrostatic system.

0 - 500PSI (34.5Bar)

0 - 5000PSI (345Bar)

Pressure gauges

C1699

C1704

C1697

C1698

Vacuum gauge

30in. Hg

Adapter fittings

Caps and plugs

Loading...

Loading...