2-34

2

DRIVE MOTOR 2.12

5 Inspect the balance plate for scratches or wear (fig.

C262).

6 Inspect the splines on the valve drive and geroler

drive for wear.

7 Inspect the keyway and chamfers on the output shaft

for sharp edges or burrs which could damage the shaft

seal.

8 Inspect the face of the bearing housing (fig. C263)

for scratches or wear.

Inspection (cont’d)

Assembly

C262

C263

C264

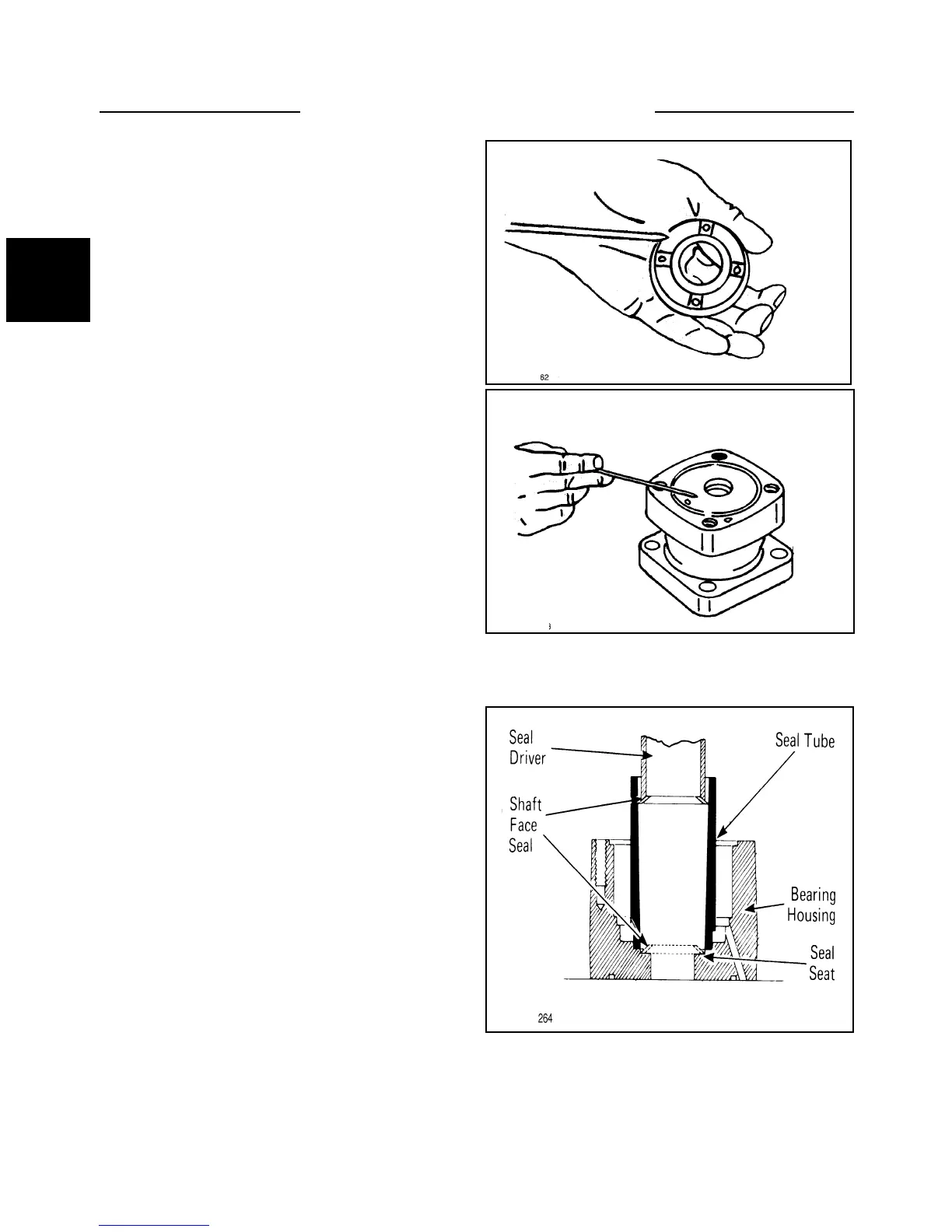

Install new seals when reassembling the torque motor.

Lubricate the seals a light grease such as petroleum jelly

prior to assembly.

1 Install the shaft face seal in the bearing housing

using a suitalble tool to seat the seal (fig. C264)

Place the bearing housing on a smooth, flat surface with

the largest open end of the housing facing upward.

Align the small I.D. end of the seal installation tube with

the seal seat in the housing (fig. C264). Apply light

grease to the seal. Install the seal in the bore of the

installation tube as shown. Insert the seal driver in the

tube and push the shaft seal with a rotating action until it

is seated.

Check for correct installation. A damaged shaft face seal

will cause losss of internal lubrication and result in parts

wear.

Loading...

Loading...