ElectricalSystemQuickChecks

TestingtheBattery(OpenCircuitTest)

Useamultimetertomeasurethevoltagebetweenthebatteryterminals;referto

BatteryTestT able(page5–39).

SetthemultimetertotheDCvoltssettings.Thebatterymustbeatatemperature

of16°Cto38°C(60°Fto100°F).EnsurethatthekeyswitchisintheOFFposition

andalltheaccessoriesareturnedoff.

Connectthepositive(+)multimeterleadtothepositivebatterypostandnegative

(-)multimeterleadtothenegativebatterypost.

Measureandrecordthebatteryvoltage.UsetheBatteryT estT able(page5–39)

todeterminechargelevelofthebattery.

Note:Thistestprovidesarelativeconditionofthebattery.Theloadtestingof

thebatteryprovidesadditionalandmoreaccurateinformation;refertoServicing

theBattery(page5–94).

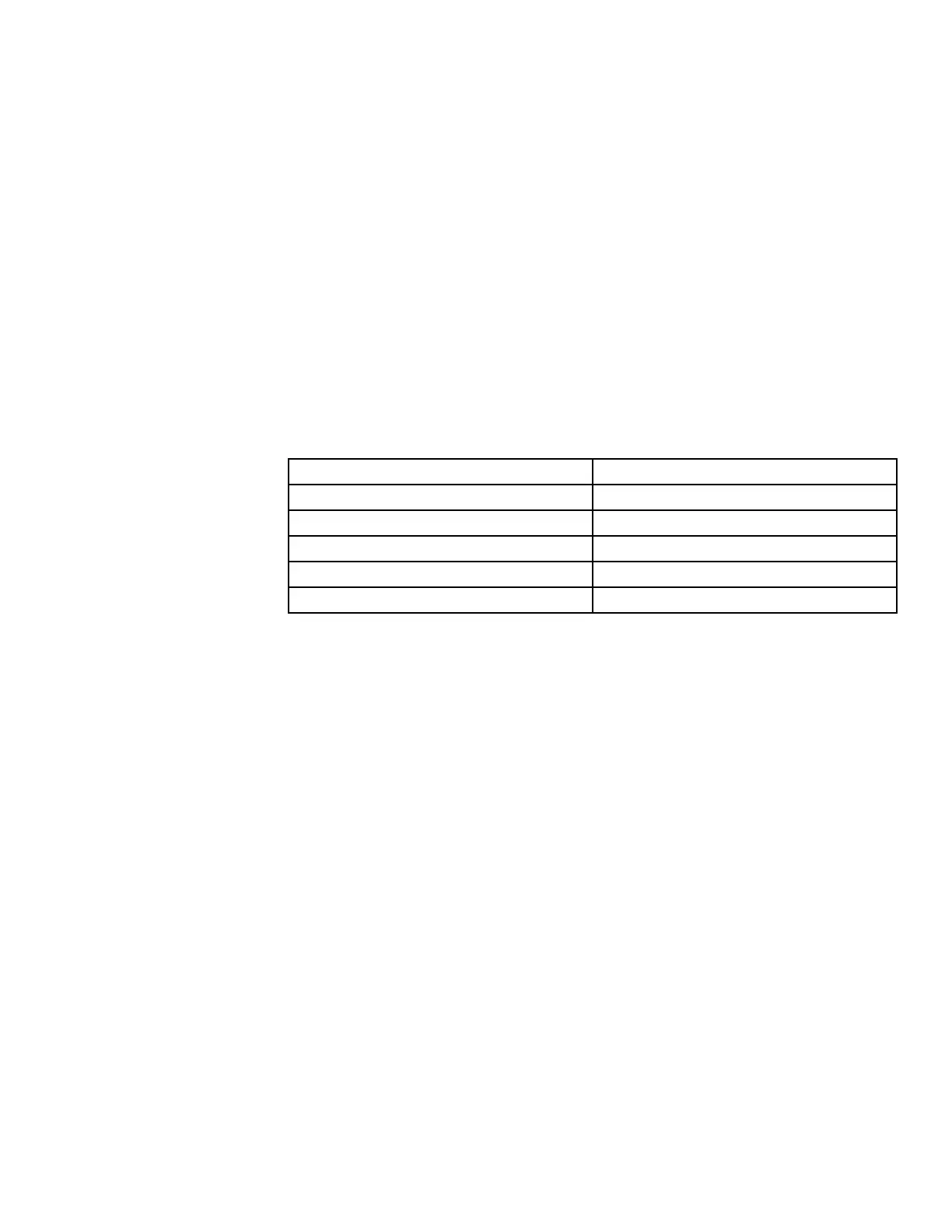

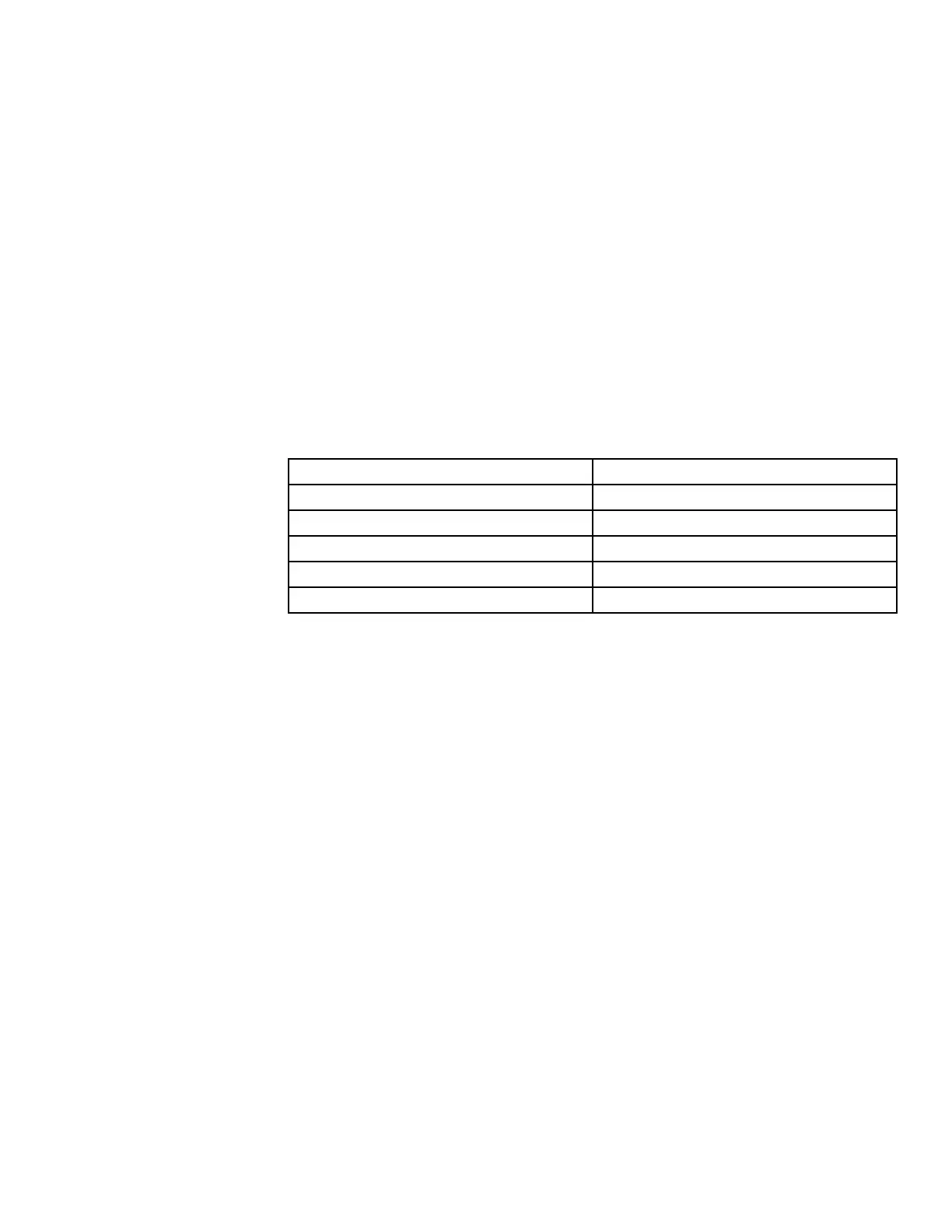

BatteryTestTable

VoltageMeasured

BatteryChargeLevel

12.68V(orhigher)Fullycharged(100%)

12.45V

75%charged

12.24V

50%charged

12.06V

25%charged

11.89V

0%charged

TestingtheChargingSystem

Thisisasimpletestthatdeterminesifachargingsystemisfunctioning.Ittells

youifthechargingsystemhasanoutput,butnotitscapacity.

Note:TheInfoCenterdisplaycanbeusedtoidentifybatteryvoltageduring

theoperationofthemachine.

Toolrequired:DigitalmultimetersettoDCvolts.

Testinstructions:Connectthepositive(+)multimeterleadtothepositivebattery

postandnegative(-)multimeterleadtothenegativebatterypost.Keepthetest

leadsconnectedtothebatterypostsandrecordthebatteryvoltage.

Note:Whenstartingtheengine,thebatteryvoltagedropsandthenmust

increaseoncetheengineisrunning.

Note:Dependingupontheconditionofthebatterychargeandbattery

temperature,thebatteryvoltageincreasesatdifferentratesasthebattery

charges.

Starttheengineandrunitathigh-idlespeed(3,005to3,055rpm).Allowthe

batterytochargeforaminimumtimeof3minutes.Recordthebatteryvoltage.

Note:Afterrunningtheengineforaminimumtimeof3minutes,thebattery

voltagemustbeminimum0.50Vhigherthanthatoftheinitialbatteryvoltage.

RefertotheBatteryVoltageT able(page5–40)foranexampleofacharging

systemthatisfunctioning.

Groundsmaster

®

4300-D

Page5–39

ElectricalSystem:ElectricalSystemQuickChecks

16226SLRevC

Loading...

Loading...