CDHH-SVX003C-EN

101

• If the carbon temperature exceeds 120 percent of

the regeneration temperature setpoint, the

controller issue a latching diagnostic, Purge Carbon

Regeneration Temperature Limit Exceeded. The

purpose of this diagnostic is to identify a failed

heater relay or temperature sensor. It disables the

purge and open the exhaust solenoid valve.

4. Close the regeneration solenoid valve and turn off the

heater.

5. The carbon capacity is reset to 100 percent.

6. The purge refrigeration circuit is turned on to allow the

carbon tank to cool for 4 hours or until the carbon

temperature reaches 100°F (37.8°C), whichever comes

first.

• If the carbon temperature does not decrease more

than 25°F (13.9°C) in the first hour, the controller

generates a latching diagnostic Purge

Regeneration Cooldown Temp Too High. The

purpose of this diagnostic is to identify a failed

heater relay or temperature sensor. The diagnostic

will disable the purge and open the exhaust

solenoid valve.

7. The exhaust solenoid will open for 5 minutes and then

close.

8. The refrigeration circuit is run for 15 minutes and allows

pumpouts during this time.

• A small amount of non-condensable gas resident in

the carbon tank will be returned to the chiller during

a regeneration cycle. Operating the refrigeration

circuit during the carbon cool-down cycle will allow

time to accumulate this gas in the purge tank in

readiness for the non-condensable pumpout

controls to be reactivated following completion of

the cool down cycle.

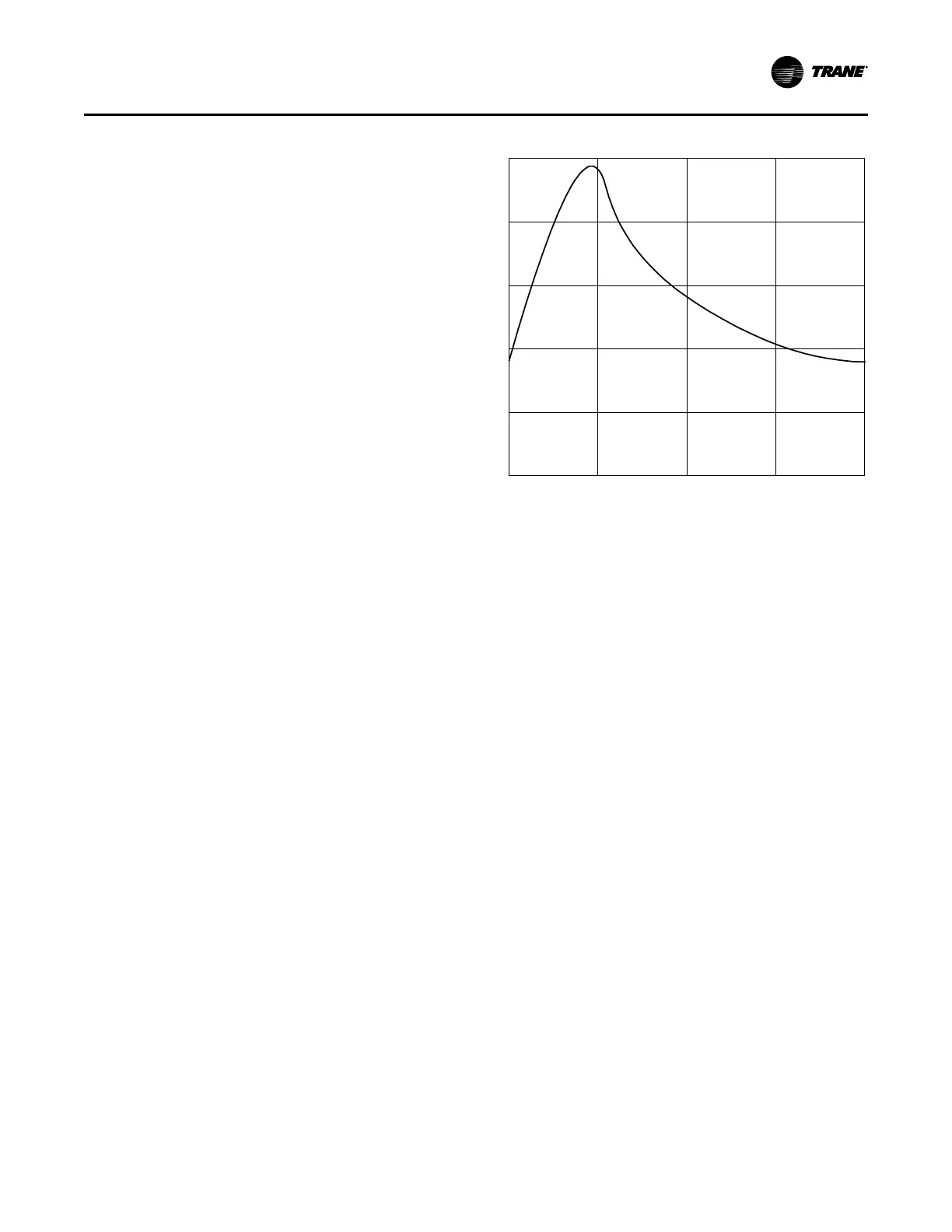

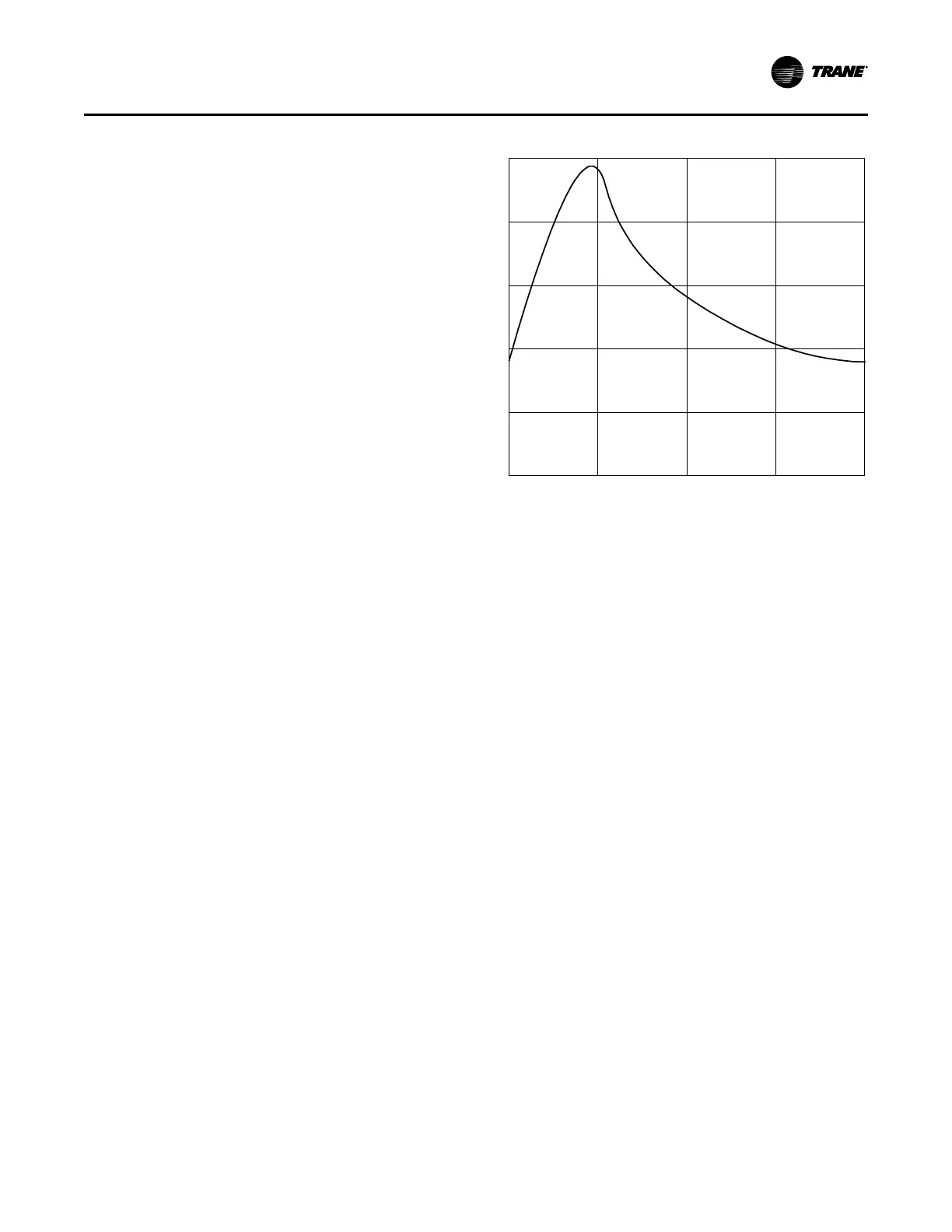

The complete regeneration cycle can take as long as

seven hours to accomplish but an average chiller does not

have to regenerate very often. A typical regeneration cycle

is depicted in the following figure.

Figure 69. Typical carbon regeneration cycle

Purge Status Points

Note: The status points appear on the purge component

screen of the Tracer

®

AdaptiView™ display. The

purge component screen is accessible from the

purge touch target on the home screen of the display.

• Time Until Next Purge Run. Displayed if the purge is

in Adaptive mode and is idle. It indicates the amount of

time left on the adaptive cycle timer.

• Daily Pumpout—24 Hours. Indicates the daily

pumpout time for the last 24 hours (a moving 24-hour

window). It indicates how the hermetic integrity of the

chiller compares to historic pump-out times for the

same chiller. It also allows a check against factory-

recommended values.

• Average Daily Pumpout—7 Days. Indicates the

average daily pump-out time for the last 168 hours (a

moving 168-hour window). It enables a comparison of

present pump-out times to past averages, and can be

another indication of the hermetic integrity of the chiller.

• Daily Pumpout Limit/Alarm. Indicates the limit value

that an operator has set in the Settings menu. When

the daily pumpout rate exceeds this value, purge

operation stops and a diagnostic is generated.

• Chiller On—7 Days. Indicates the percentage of time

during the past seven days (floating 168-hour window)

that the chiller was operating. You can use it to help

determine if a leak is present on the high side or the low

side of the chiller.

• Pumpout Chiller On—7 Days. Indicates the

percentage of the total purge pump-out time during the

past seven days that occurred while the chiller was

operating. You can use it to help determine if a leak is

present on the high side or the low side of the chiller.

Start-up and Shutdown

Loading...

Loading...