Fault clearance

What to do if...

97

Fault clearance

This section informs you what to do if a malfunction occurs. A disturbance

can have various different causes.

For instructions on the respective fault clearances that may be carried out by

technical personnel as defined under "Personnel qualification", please refer

to the section "Fault clearance". It is essential to observe the safety instruc-

tions within the respective section.

What to do if...

Mechanical malfunctions

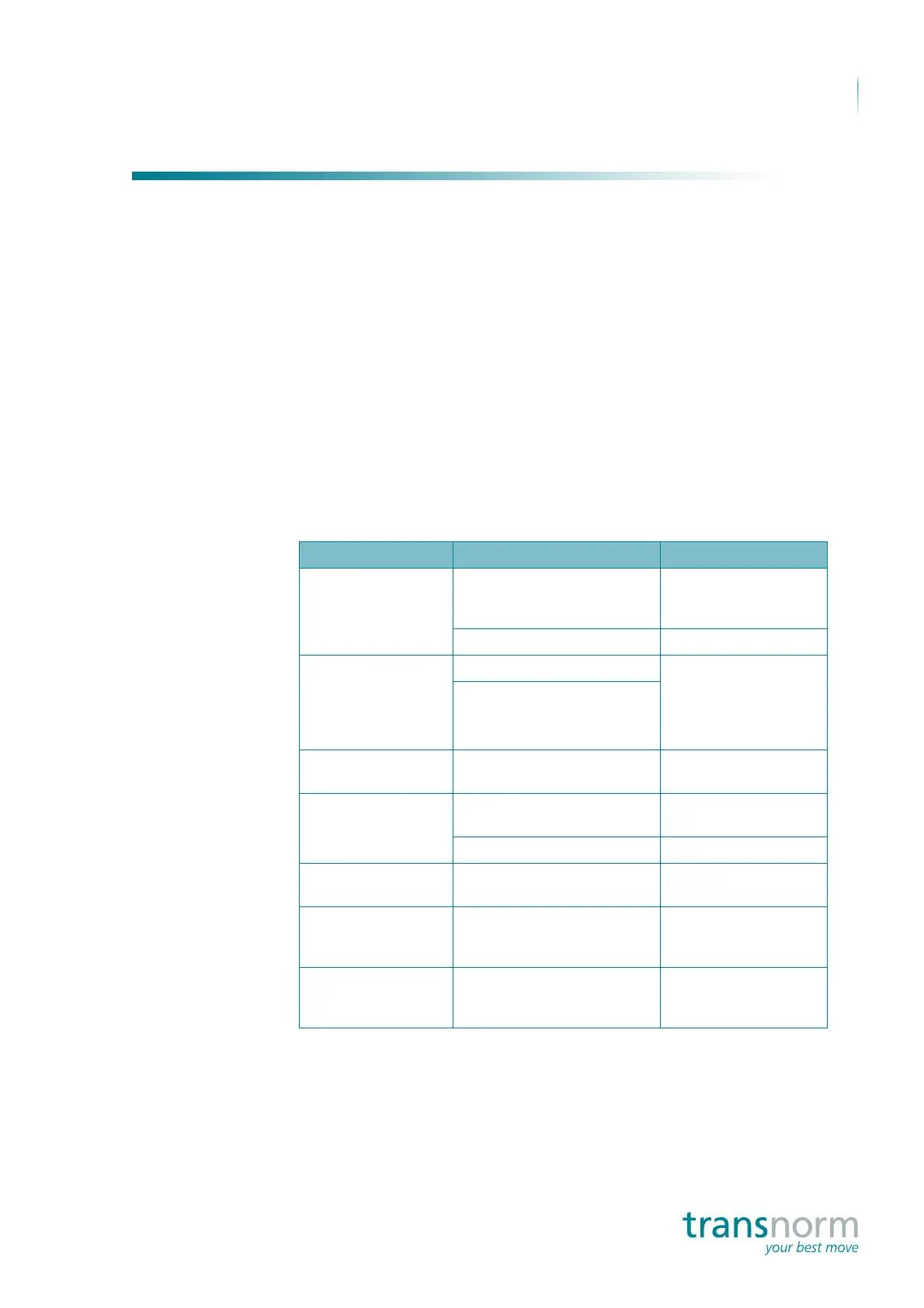

Detected disturbance Possible cause Remedial action

Machine shuts down Power supply disrupted,

error message

Have technical personnel

establish and eliminate

the problem

Motor defect Replace motor

Machine shutdown with

running motor

Drive belt slips Check belt tension,

increase if necessary

Replace belt

Check all driven shafts

for smooth running

Drive belt torn

Individual swivel rollers

stand still

Round belt defective Replace round belt

No swivelling function Pneumatic cylinder defective Replace pneumatic

cylinder

Solenoid valve defective Replace solenoid valve

Noise in conveyor

rollers/pulleys

Inner bearing ring turning on

shaft, bearing defective

Replace conveyor

rollers/pulleys

Noise development in

the bearings of the

swivel roller bar

Worn bearings Replace swivel unit /

have swivel unit over-

hauled

Evident angular devia-

tion of single swivel

rollers

Plain bearing bushing is worn Replace swivel unit /

have swivel unit over-

hauled

Loading...

Loading...