3

vacon • 16 Receipt of delivery

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

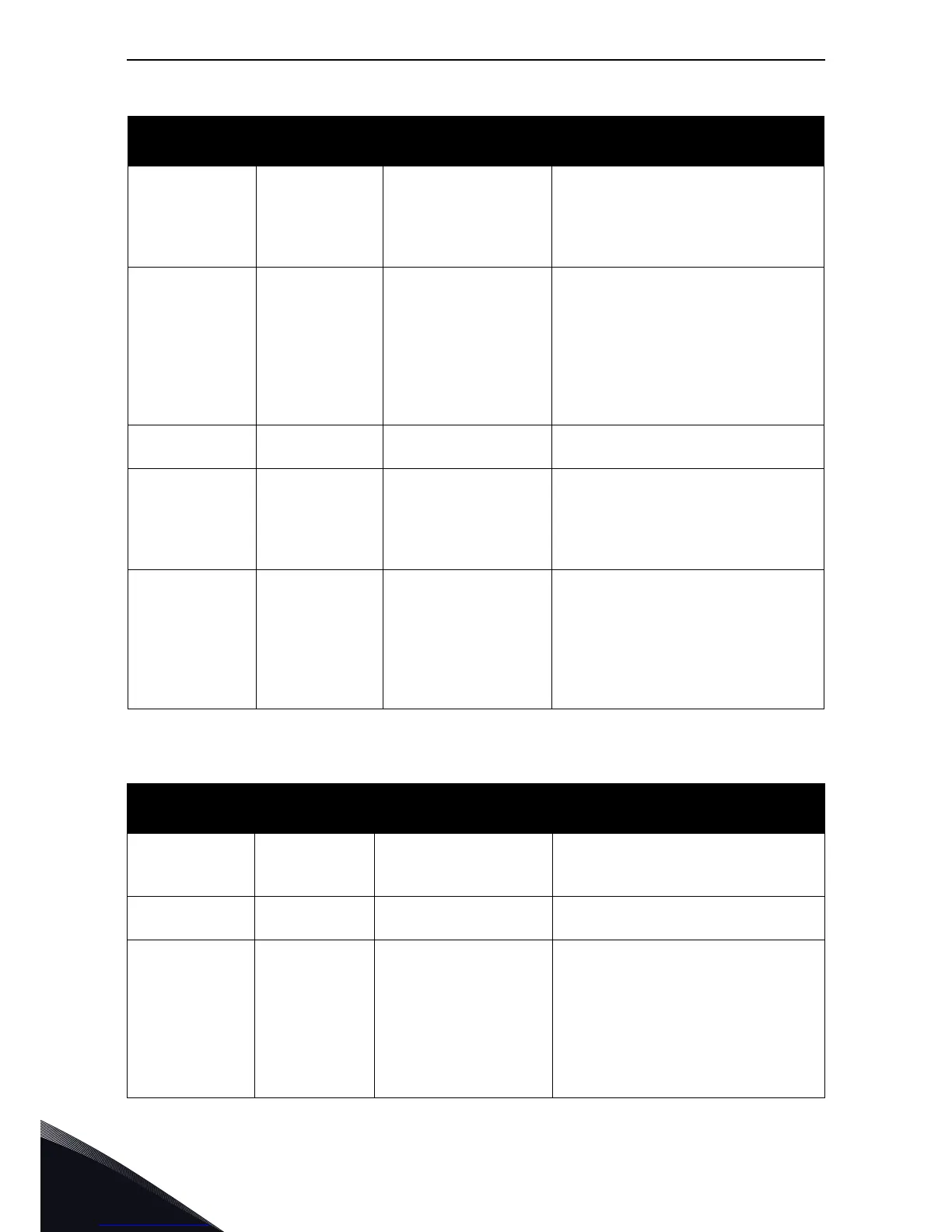

Main DC cooling

fans and and

internal cooling

fans for elec-

tronics

1 year 5 year

Replace parts according to service

schedule or based on maintenance

report recommendation.

DC-link capaci-

tors

1 year

•8 years in

demanding

environment or

heavy load

•12 years in

typical

environment or

normal load

The expected life time of the capaci-

tor is determined based on load and

the temperature of the environment.

Replace parts according to service

schedule.

Product

upgrades

1 year 1 year

Manufacturer offers product

upgrades.

Printed circuit

boards

1 year

12 years in typical

environment

The printed circuit boards to be

checked for contamination and possi-

ble corrosion. In case of contamina-

tion or corrosion printed circuit

boards to be changed.

Recommended

reforming inter-

val for electro-

lytic DC-link

capacitors (spare

parts and prod-

ucts in storage)

1 year 1 year

Reforming must be done once a year

for products and spare part capaci-

tors in storage. Ask instructions from

your local distributor.

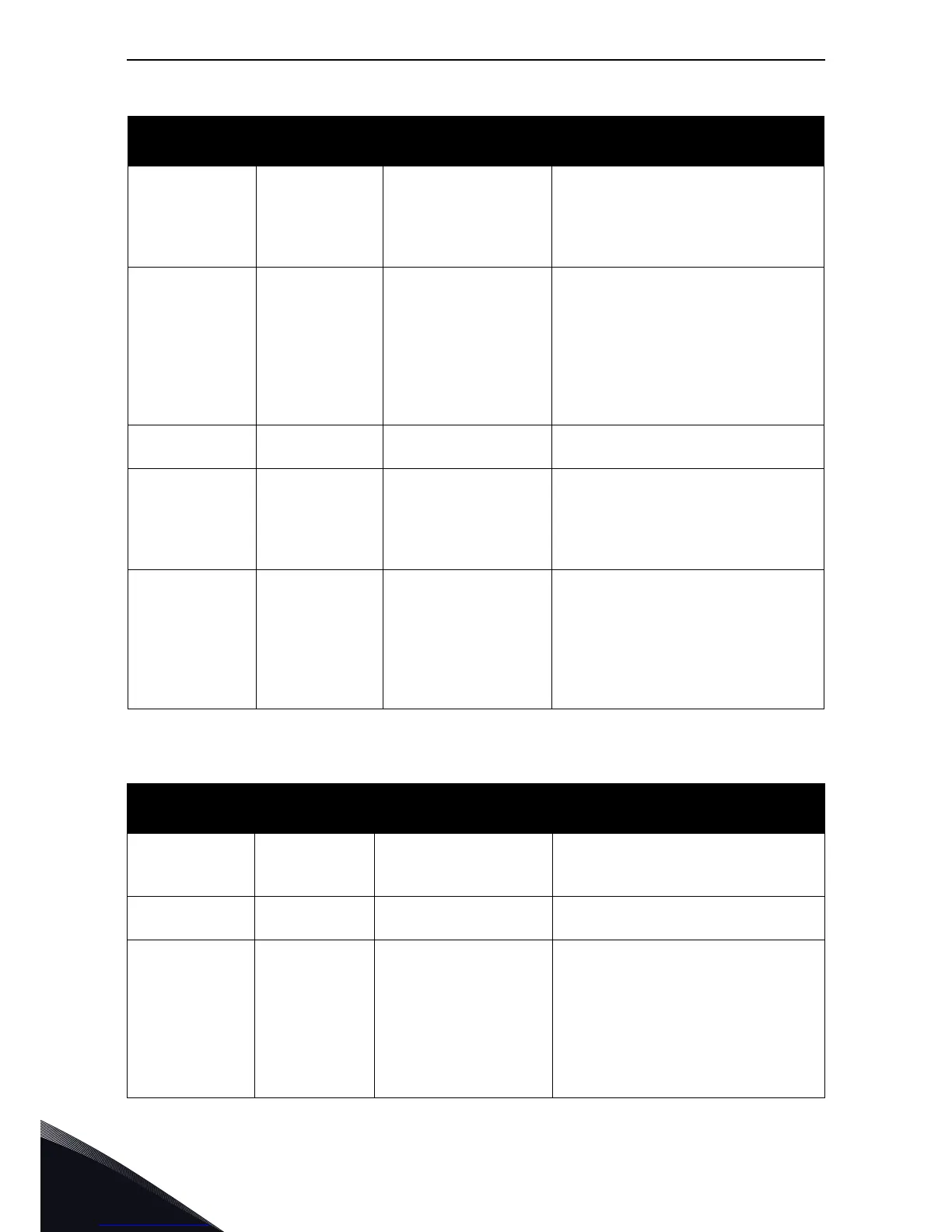

Table 3. VACON

®

Liquid-Cooled AC drive maintenance program, liquid cooling system

Inspection

target

Inspection

intervals

Service schedule Proactive maintenance actions

Coolant inhibitor 1 year 2 years

Add inhibitor according to instruc-

tions or analyze the coolant and add

inhibitor based on result.

Coolant 2 years 6 years

Check and change coolant according

to service schedule.

VACON

®

NX Liq-

uid-Cooled drive

coolant flow

1 year Based on inspection

Check pressure, flow and tempera-

ture of the system. Compare to previ-

ous measurement. Temperature

alarm or trip indicates that AC drive

warms up and the flow is to low.

Cleaning of heatsink if necessary, Ask

instructions from your local distribu-

tor.

Table 2. VACON

®

NX Liquid-Cooled AC drive maintenance program, general

Inspection

target

Inspection

intervals

Service schedule Proactive maintenance actions

Loading...

Loading...