Receipt of delivery vacon • 17

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

Coolant leakage 3 months Based on inspection

Open the cubicle doors and check

that there are no visible leaks on

cooling unit or coolant manifold con-

nections. If you find a leak, shut down

the unit and repair the leak.

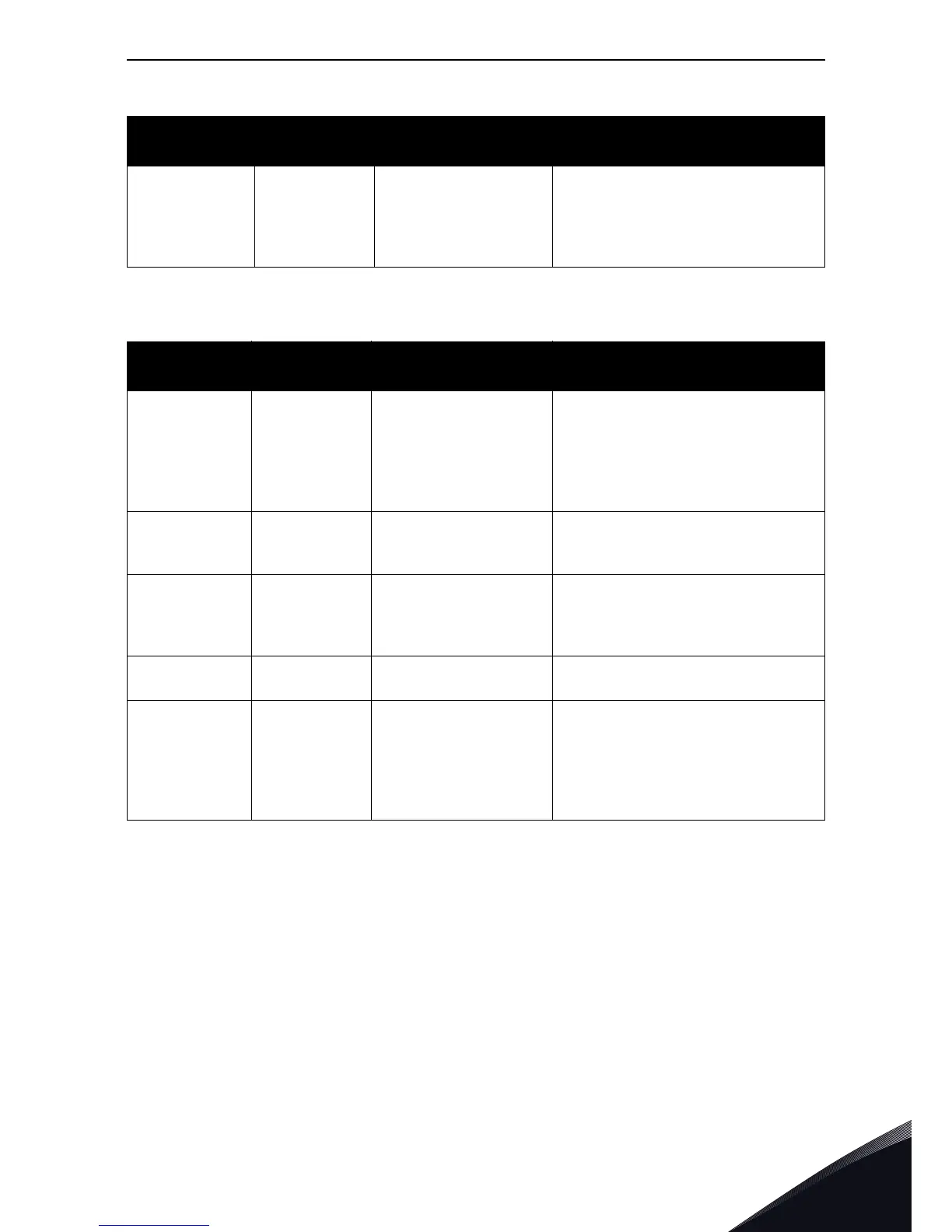

Table 4. VACON

®

Liquid-Cooled AC drive maintenance program, cabinet, cabling and connections

Inspection

target

Inspection

intervals

Service schedule Proactive maintenance actions

Cabinet, auxil-

iary devices

(contactors,

switches, relays,

push buttons,

indicators, etc.)

1 year

According to manufac-

turer information

Replace parts according to service

schedule or based on maintenance

report recommendation.

Sealings 1 year Based on inspection

Check cabinet and drive sealings.

Check visually cable bushing. Correc-

tive actions based on findings.

Visual inspec-

tion of cablings

1 year 1 year

Visual inspection for possible dam-

ages and so on, due to, for example,

vibration. Actions based on inspec-

tion.

Tightness of

connections

1 year 1 year

Check and tighten the cable and wire

connections.

Radiator cool-

ing fans and

control com-

partment fans

1 year 5 years

Check the operation of the fans and

measure the radiator fan capacitor

every 2 years. Replace parts accord-

ing to service schedule or based on

maintenance report recommenda-

tion.

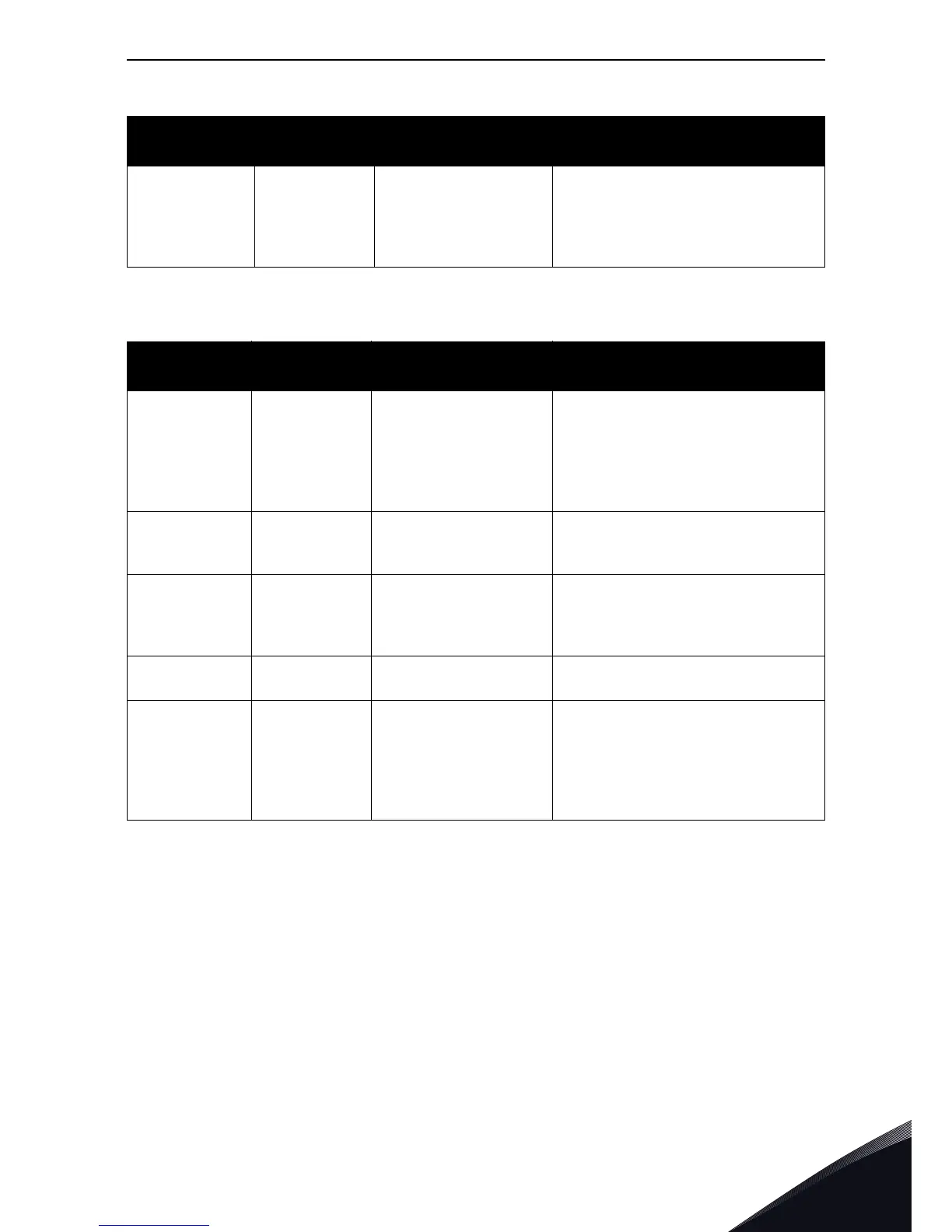

Table 3. VACON

®

Liquid-Cooled AC drive maintenance program, liquid cooling system

Inspection

target

Inspection

intervals

Service schedule Proactive maintenance actions

Loading...

Loading...