Vacuum Packaging Machine VC999 K7

Error display and troubleshooting

2008-11-26 Art.-No. 592.016 Page 73/121

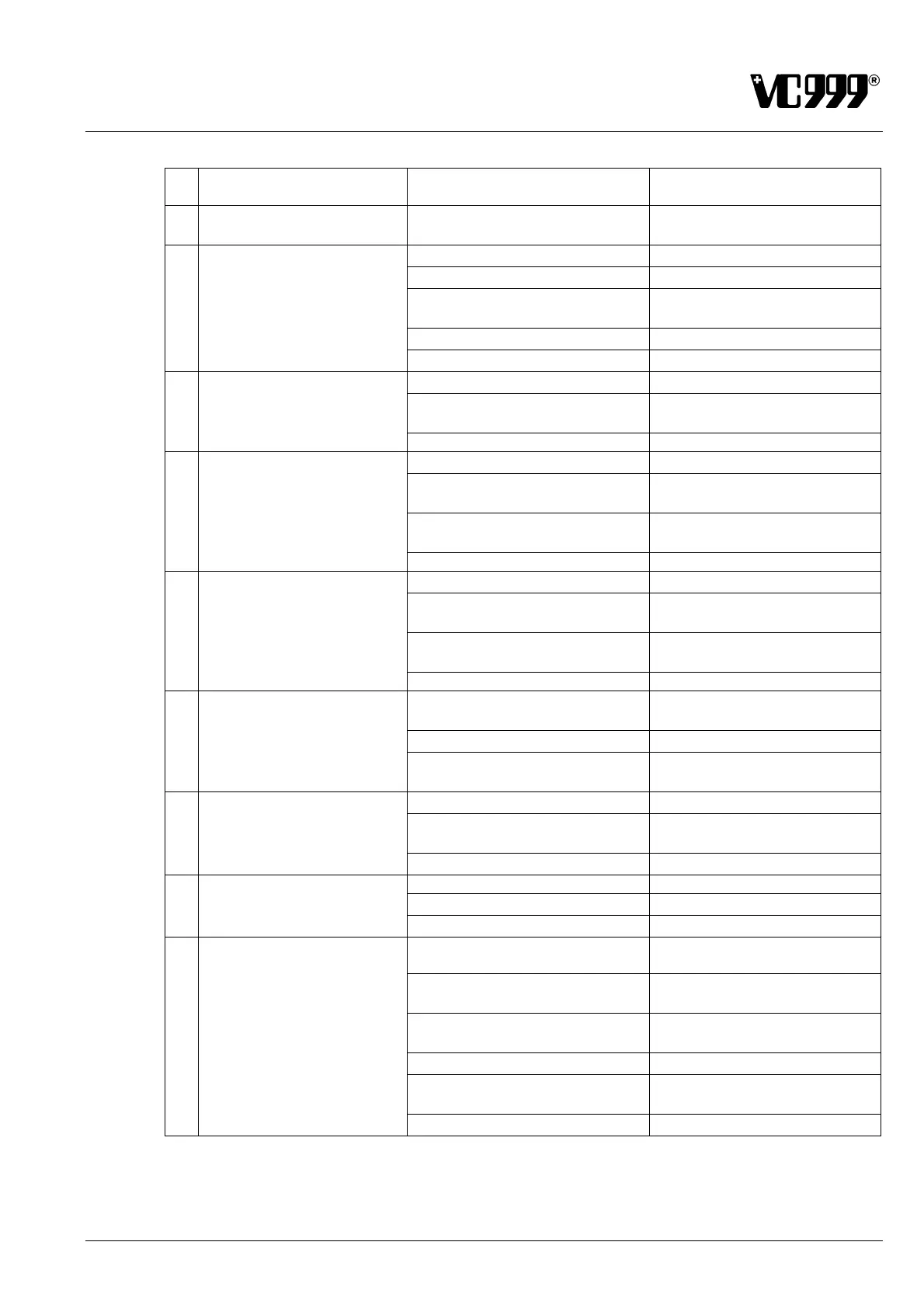

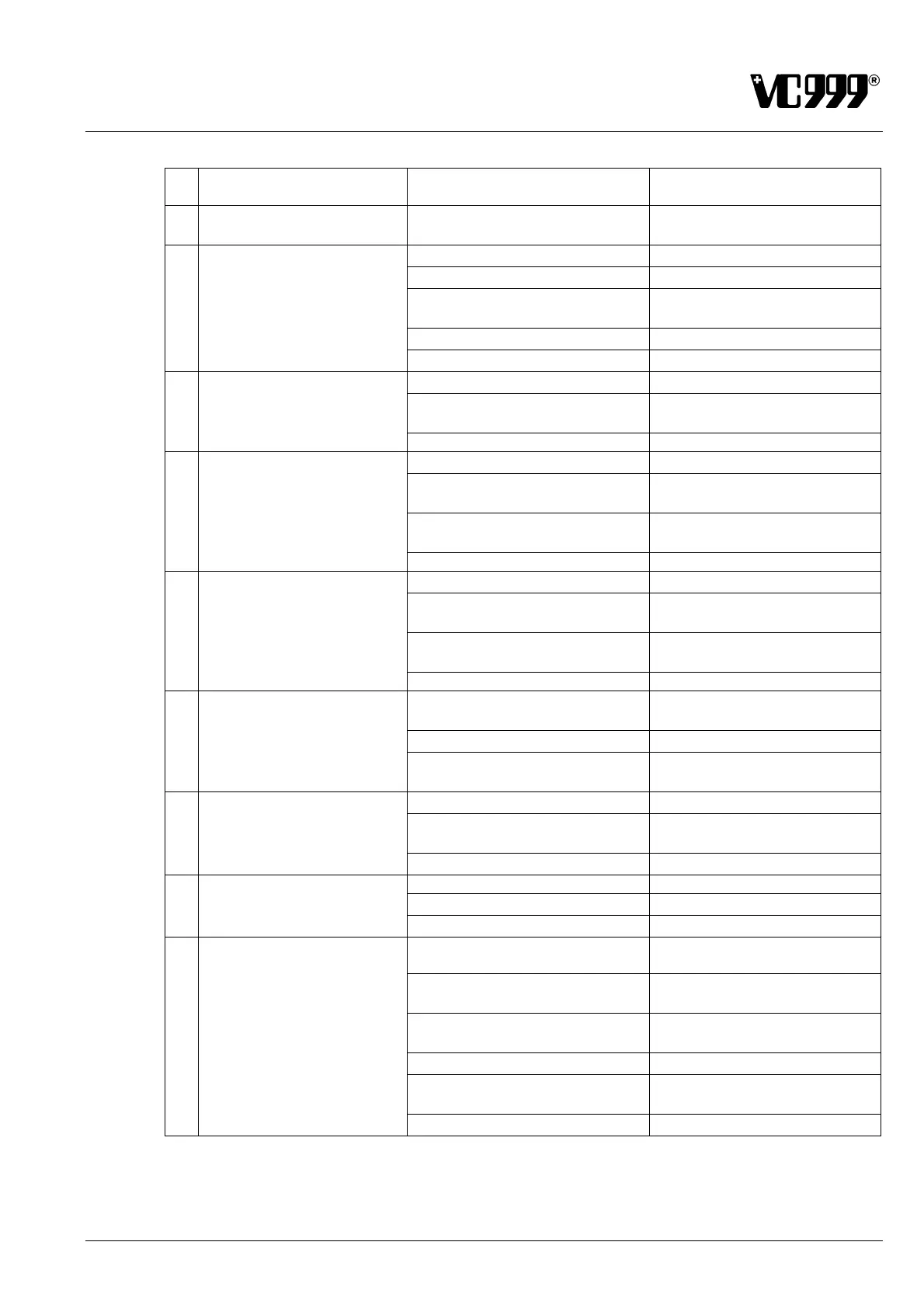

No Alarm messages Cause Remedy

1

Hand safety-guard monitor-

ing actuated

Resistance of lid on closure Remove foreign matter from

sealing area

Compressed air not connected

Connect compressed air

Main valve on mains closed

Open main valve

Leak in compressed air supply

line

Check supply line for leaks,

remedy leaks where necessary

Setting on FRL unit too low

Check: setting at approx. 5 bar

2

Compressed air supply is

too low

Pressure switch faulty

Check pressure switch

Thermal relay setting incorrect Check thermal relay setting

Fault on vacuum pump(s)

Consult VC999 Customer Ser-

vice Dep.

3 Electric supply roots pump

Pump overheats Leave pump to cool down

Thermal relay setting incorrect Check thermal relay setting

Fault on vacuum pump(s)

Consult VC999 Customer Ser-

vice Dep.

Oil removal filter of pump blocked

Exchange oil separator ele-

ments

4

Electric supply rotary slide

pump 1

Pump overheats Leave pump to cool down

Thermal relay setting incorrect Check thermal relay setting

Fault on vacuum pump(s)

Consult VC999 Customer Ser-

vice Dep.

Oil removal filter of pump blocked

Exchange oil separator ele-

ments

5

Electric supply rotary slide

pump 2

Pump overheats Leave pump to cool down

Current value setting on the fre-

quency converter is too low

Check setting in frequency

converter

Strained running of conveyor belt Check transport area

6

Error frequency converter

conveyor belt

Gearmotor defective

Consult VC999 Customer Ser-

vice Dep.

Thermal relay setting incorrect F3 Check thermal relay setting

Fan defect

Consult VC999 Customer Ser-

vice Dep.

7

Electric supply bag waste

suction unit is interrupted

Fan overheated Leave fan to cool down

Air intake filter blocked Check air intake filter and clean

Valve faulty

Check preliminary venting valve

8

Preventilation set point not

reached

Selected set value too low

Select higher set value

Vacuum pump(s) not operating at

full capacity

Carry out oil change

Product evaporates under vac-

uum

Select vacuuming type „Vac-

uuming to evaporation“

Vacuum chamber does not close

fully

Check sealing area and actua-

tion mechanism

Vacuum chamber not leak-tight

Check lid seal and hoses

Vacuum chamber damp

Dry out vacuum chamber and

belt

9

Vacuum set point not

reached

Incorrect calibration

Carry out sensor calibration

Loading...

Loading...