Vacuum Packaging Machine VC999 K7

Error display and troubleshooting

Page 74/121 Art.-No. 592.016 2008-11-26

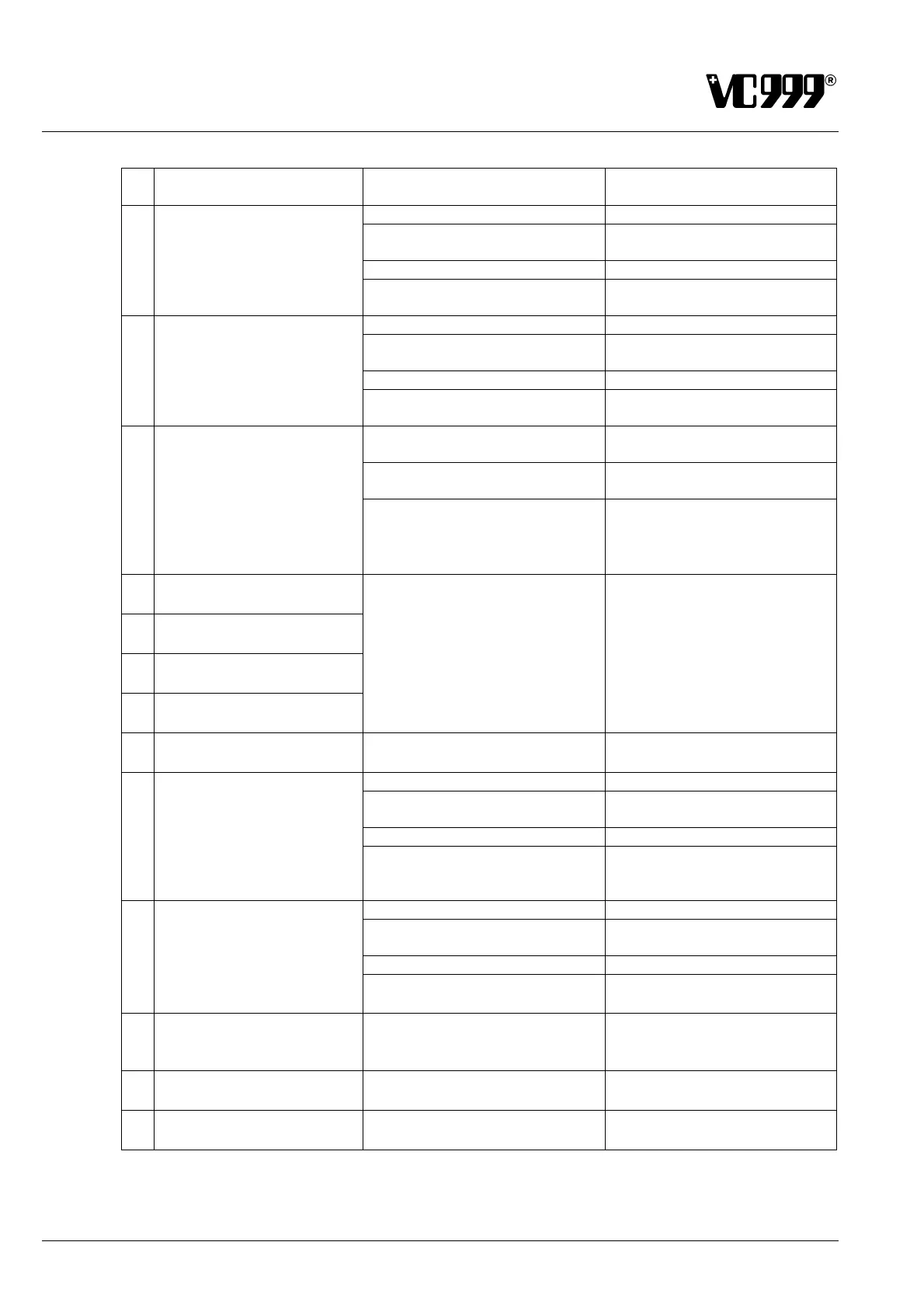

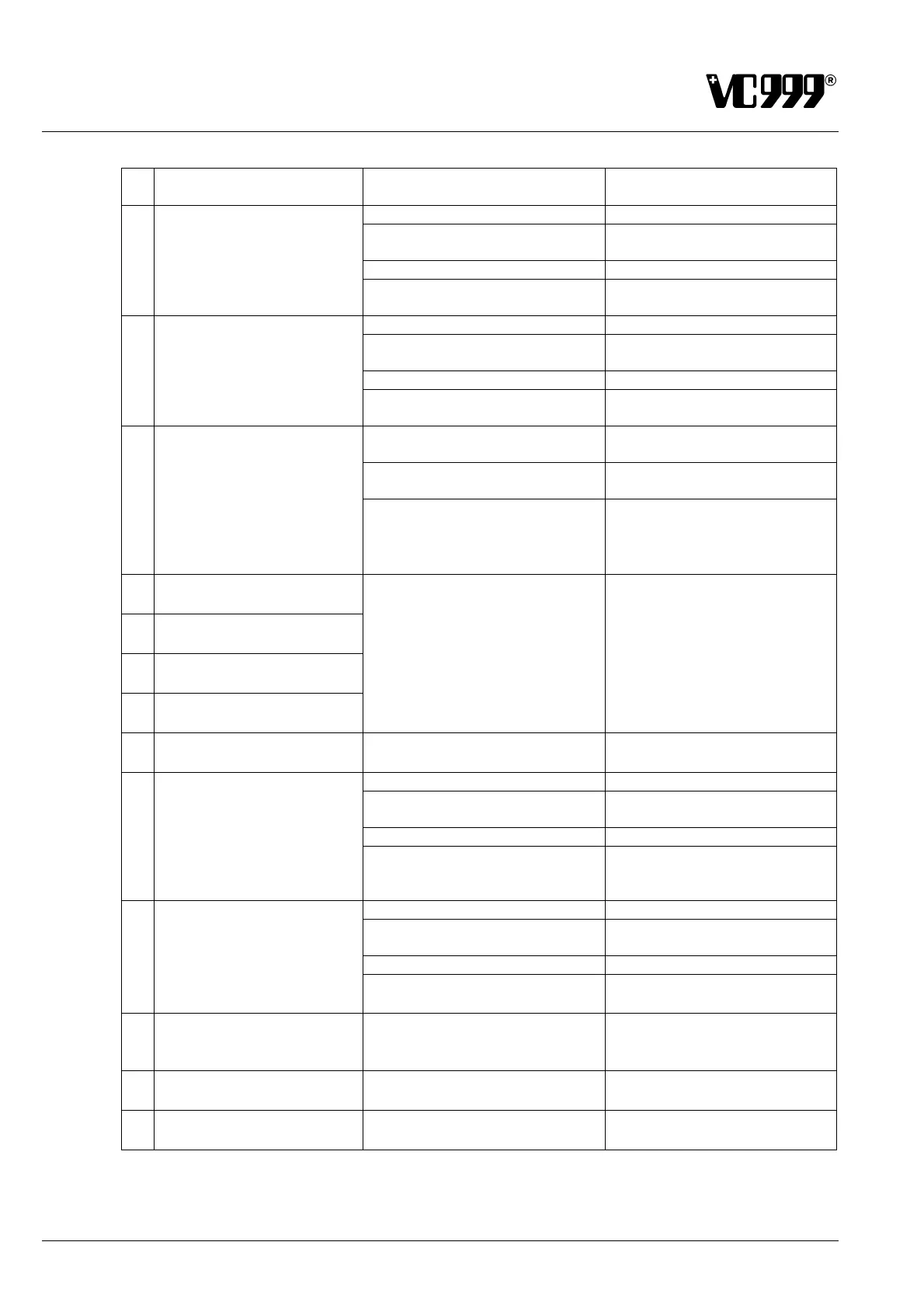

No Alarm messages Cause Remedy

Limit switch position incorrect Check limit switch position

Mechanical obstruction to

movement

Check mechanical movement

Limit switch faulty Exchange limit switch

10

Limit switch for top lid posi-

tion not reached

Fault in electrical supply of limit

switch or valves

Consult VC999 Customer Ser-

vice Dep.

Limit switch position incorrect Check limit switch position

Mechanical obstruction to

movement

Check mechanical movement

Limit switch faulty Exchange limit switch

11

Limit switch for bottom lid

position not reached

Fault in electrical supply of limit

switch or valves

Consult VC999 Customer Ser-

vice Dep.

Initiator/belt switching distance

too large

Check switching distance

(set value = 1 - 2 mm)

Initiator soiled or faulty Clean initiator and replace if

necessary

12

Conveyor belt positioning

mark not found

Conveyor belt faulty

Please read the description

"Start conveyor belt position" in

Mask 52: Test function. If nec-

essary, replace the belt.

13

Distance of left-hand sealing

bars too big

14

Distance of right-hand seal-

ing bars too big

15

Distance of right-hand seal-

ing bars too small

17

Distance of left-hand sealing

bars too small

Top and bottom sealing bars not

set at the correct

Check height of sealing bars

16 Internal PLC error Fault in PLC

Read fault code and consult

VC999 Customer Service

Limit switch position incorrect Check limit switch position

Mechanical obstruction to

movement

Check mechanical movement

Limit switch faulty Exchange limit switch

18

Vacuum chamber could not

be closed

Fault in electrical supply of limit

switch or valves

Consult VC999 Customer Ser-

vice Department

Limit switch position incorrect Check limit switch position

Mechanical obstruction to

movement

Check mechanical movement

Limit switch faulty Exchange limit switch

19

Vacuum chamber could not

be opened

Fault in electrical supply of limit

switch or valves

Consult VC999 Customer Ser-

vice Department.

20 Alarm temperature controller Fault in the sealing system

Read error code, discover and

eliminate the fault using the

table "error codes for alarm 20".

21

Calibration of temp. control-

ler cannot be started

Sealing bars are too hot Allow sealing bars to cool down

22

Calibration of temp. control-

ler cannot be stopped

Autocalibration fault Check wiring

Loading...

Loading...