Vacuum Packaging Machine VC999 K7

Error display and troubleshooting

2008-11-26 Art.-No. 592.016 Page 75/121

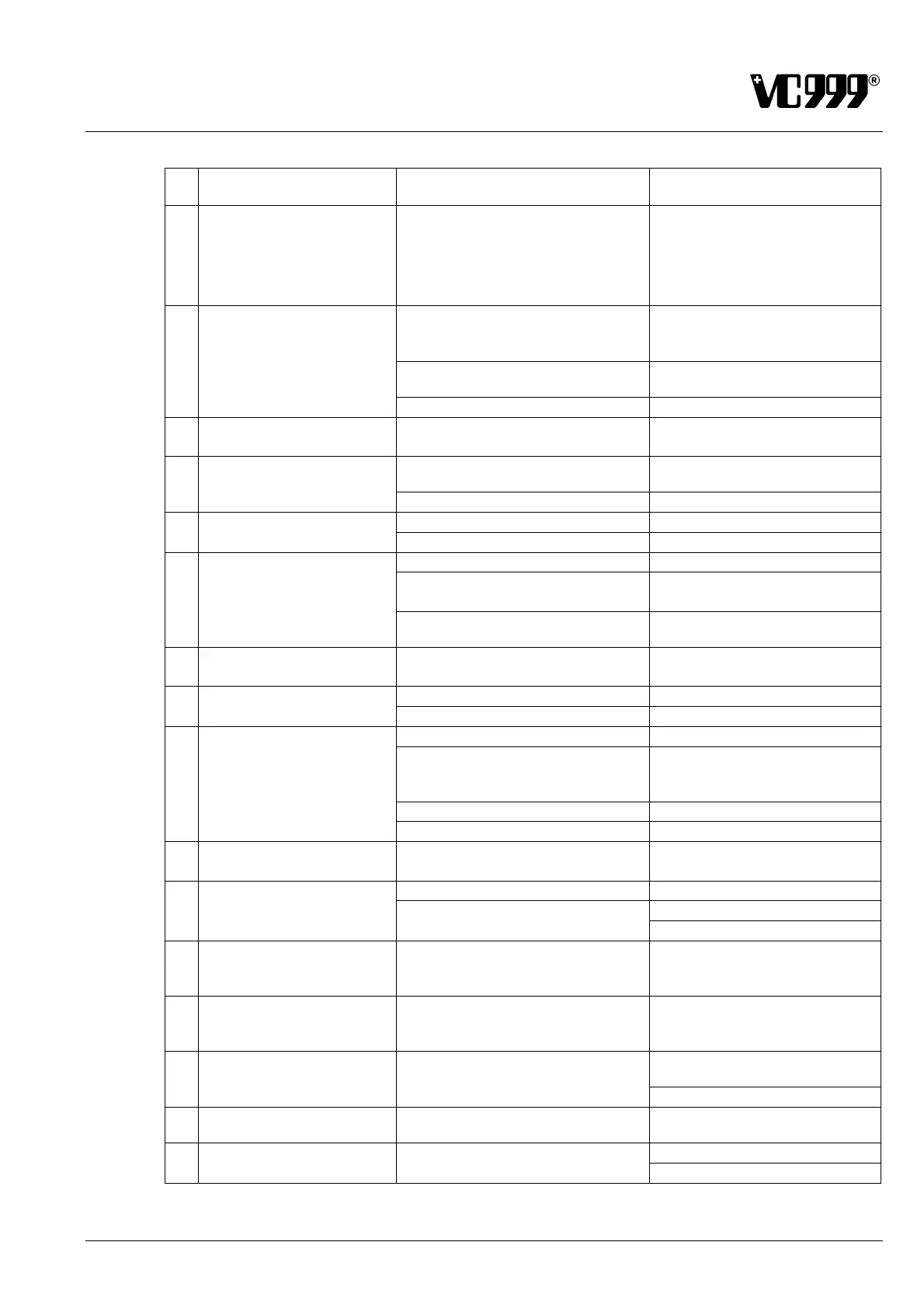

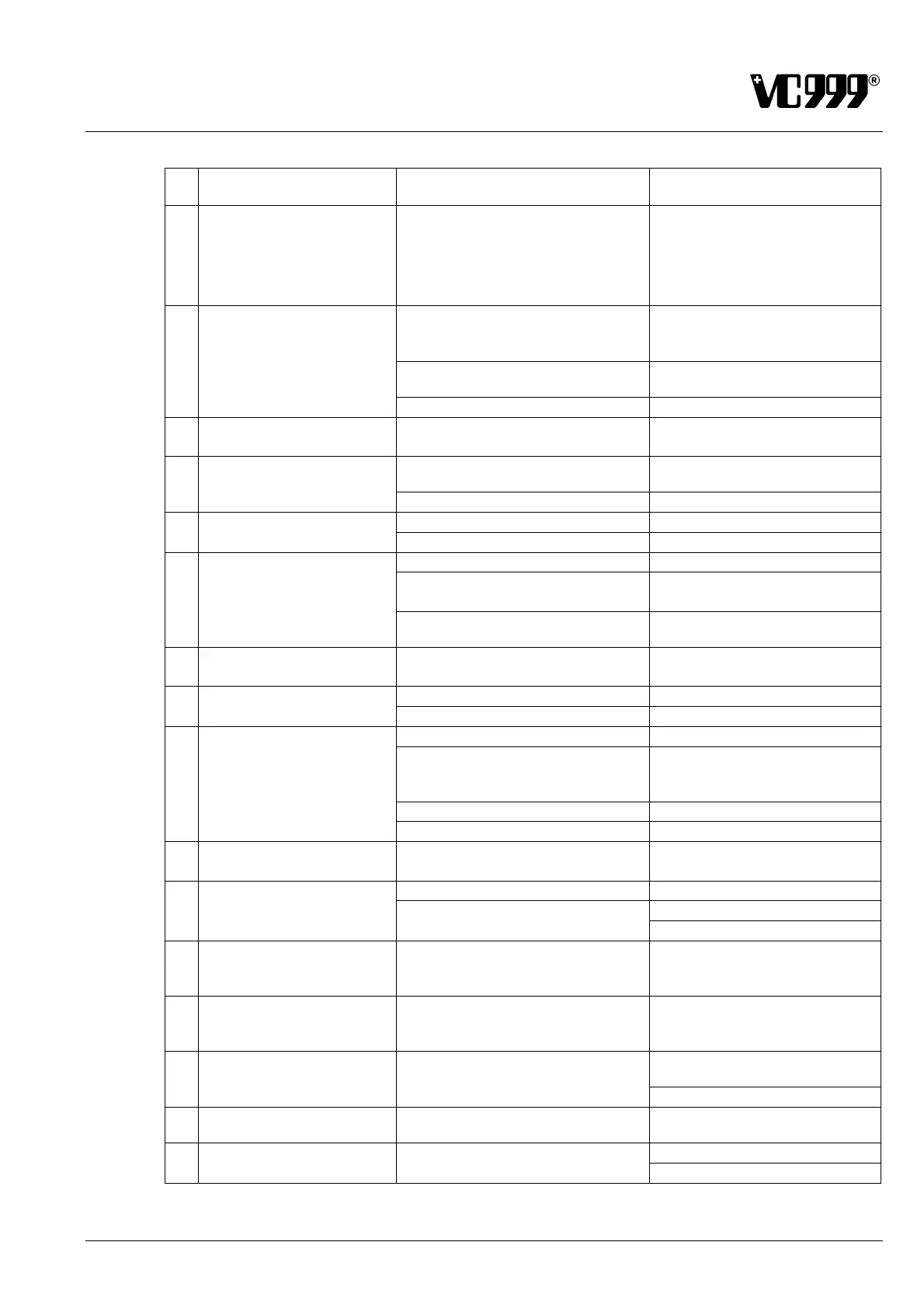

No Alarm messages Cause Remedy

23 PLC battery voltage too low

This message appears if the charge

state of the PLC buffer battery is too

low.

The battery should be replaced as

quickly as possible, and be re-

moved and installed within 20

seconds. If necessary, contact the

VC999 Customer Service Depart-

ment!

Temperature control device may be

switched off

Make sure the temperature control

device is switched on

El. supply of the temperature control

device may be interrupted

Check el. supply of the tempera-

ture control device

24

Set temperature sealing bars

not reached

Calibrate sealing bars

25

Temperature monitoring of

pumps has triggered

Overheating of the vacuum pump Allow pump to cool down.

Carry out possible pump service

Input value of the set temperature is

less than the actual temperature

Check the input value of the set

temperature

26

Actual temp. sealing bars is

higher than set point

Error in the temperature control circuit Carry out calibration

Incorrect thermal relay setting Check thermal relay setting 27

El. supply of the rotary blade

interrupted

Rotary blade motor overheated Allow motor to cool down

Mechanical movements hindered Check mechanical movement

Limit switch defective

Replace limit switch

28

Machine is not in initial posi-

tion

El. supply line to the limit switch or

valve defective

Consult VC999 Customer Service

Department

29

Cooling temperature not

reached

Error in the temperature control circuit

Re-calibrate

Burn-in sealing bars

Check input value Change input value 30

Ventilation set point not

reached

Air flow interrupted Check for soiling

Conveyor belt motor drive overheated Check thermal relay setting

Conveyor belt motor drive defective

Consult VC999 Customer Service

Department

Motor drive overheated Allow motor drive to cool down

31

Temp. monitoring motor con-

veyor belt has triggered

Conveyor belt tension too high Correct belt tension

32

Communication PLC - fre-

quency converter faulty

El. connection PLC – FC incorrect

Check el. supply of FC

Check bus CPU – FC

Incorrect calibration Calibrate vacuum system

Clean or replace vacuum sesnor

33

Measuring system: vacuum

value faulty

Vacuum sensor defective or soiled

Check el. supply of vacuum sensor

34

Error reset safety module

Emergency Stop

EMERGENCY STOP active

At least 1 EMERGENCY STOP circuit

interrupted

Release EMERGENCY STOP

35

Emergency Stop circuit is

interrupted

EMERGENCY STOP active

At least 1 EMERGENCY STOP circuit

interrupted

Release EMERGENCY STOP

Consult VC999 Customer Service

Department

36

Safety monitoring sealing

system is defective

Safety contactor sealing system defec-

tive

Replace contactor

37

Vacuum system cannot be

calibrated

Vacuum sensor defective or soiled Clean or replace vacuum sesnor

Check el. supply 38

Intermediate ventilation can-

not be carried out

Ventilation valve does not open

Check valve for soiling

Loading...

Loading...