Cleaning the working chamber

Cleaning the working chamber includes the following

components:

n

Measuring key

n

Blank holder

n

View window

n

Webcam

n

Tool magazines

n

Tool magazine holder

These components have different maintenance inter-

vals according to the maintenance table. Therefore,

you should perform a daily and a weekly cleaning of

the working chamber and clean the components

which need cleaning.

When performing the weekly cleaning, also per-

form the daily cleaning.

We recommend cleaning the working

chamber after all other required maintenance

tasks.

NOTICE

Damaging of the linear guides or the

spindle when cleaning with compressed air

or ultrasound

If you clean the working chamber with compressed air

or ultrasound, material chips can reach the linear

guides or the spindle bearings.

Never

clean the working chamber with com-

pressed air or ultrasound.

Do not pour additional water into the working

chamber. The cooling liquid tank may over-

flow.

1.

Have ready:

n

A wet cloth

n

A mild cleaning agent(optional)

n

Cleaning brush for the blank holder

n

A wet brush for the measuring key

2.

Open the working chamber door.

3.

Clean all surfaces and cracks in the working cham-

ber thoroughly with a wet cloth. Use a mild clean-

ing agent if necessary.

4.

Clean the measuring key with the wet brush.

Performing the weekly cleaning

1.

Have ready: The cleaning brush for the blank

holder.

2.

Remove the tool magazine from the working

chamber. Clean it with the cloth and the brush.

3.

Open the multi-purpose drawer. Clean the other

tool magazines.

4.

Clean the blank holder with its respective brush.

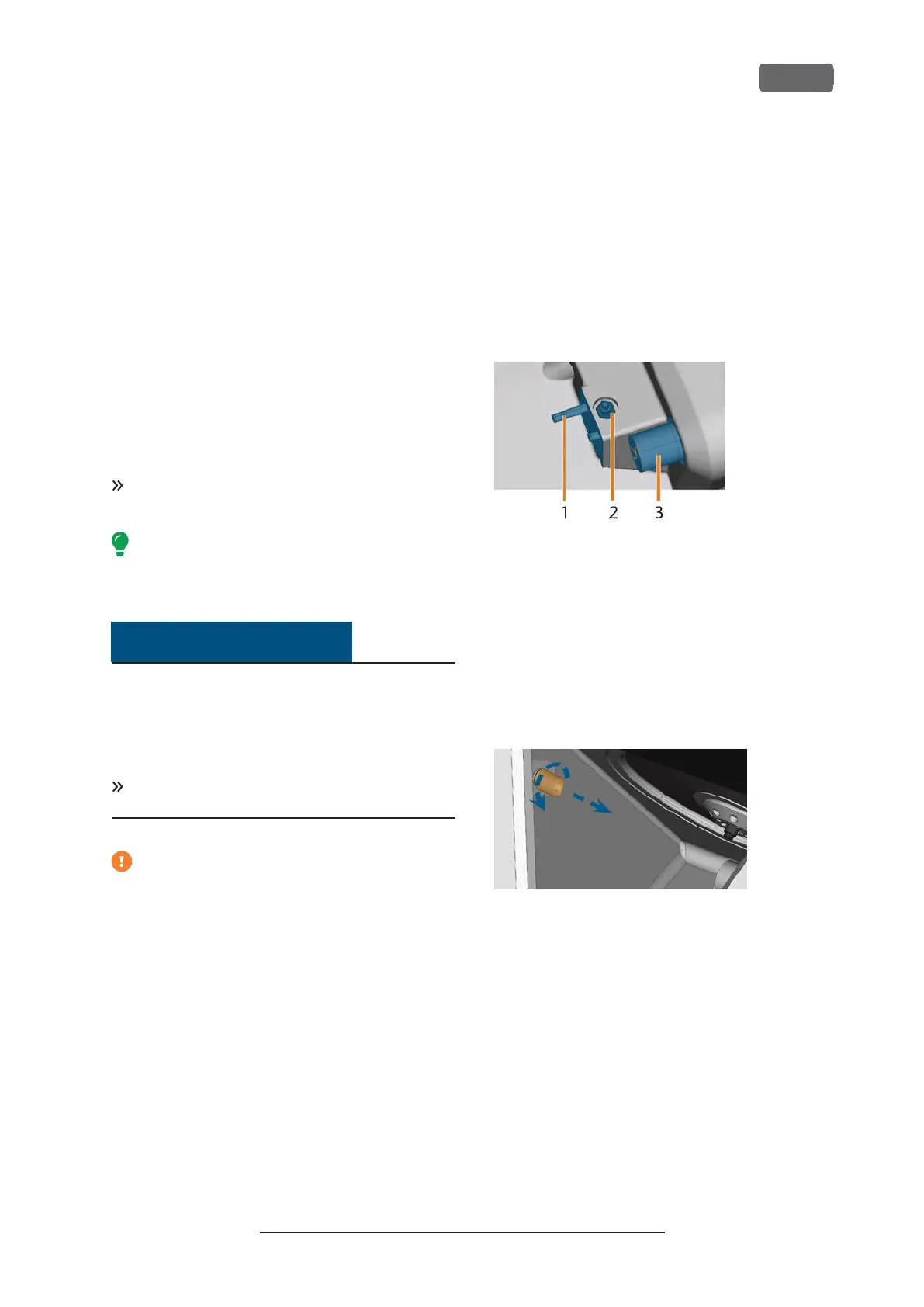

F

IG

. 67 – T

OOL MAGAZINE HOLDER

, M

EASURING KEY

, B

LOCK

HOLDER

(

IN BLUE

)

1.

Tool magazine holder

2.

Measuring key

3.

Blank holder

5.

Screw the protective cap off the webcam and

clean the inside of the cap with a dry cloth.

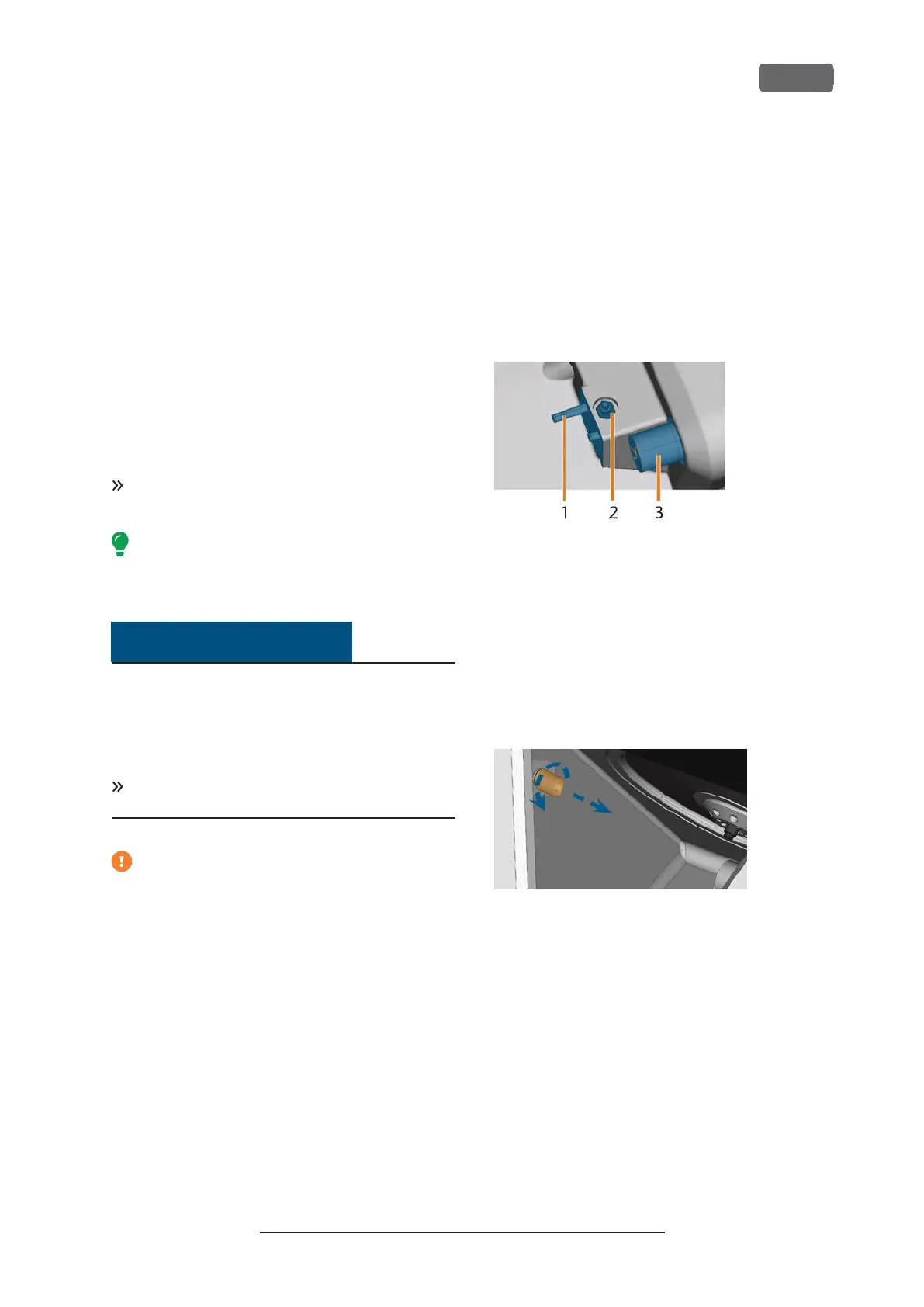

F

IG

. 68 – S

CREWING THE PROTECTIVE CAP OFF THE WEBCAM

6.

Clean the webcam with a wet cloth. Screw on the

protective cap.

7.

Clean the tool magazine holder thoroughly.

8.

Apply a bit of collet grease to the bolts of the tool

magazine holder.

9.

To apply the collet grease to the holes of all tool

magazines, mount all tool magazines once.

Z4 – Maintenance and do-it-yourself

EN 57

Original Operating Instructions:Z4

Version: 12/5/2018

Loading...

Loading...