Cleaning the nozzle plate

You should clean the nozzle plate every time you

clean the collet chuck.

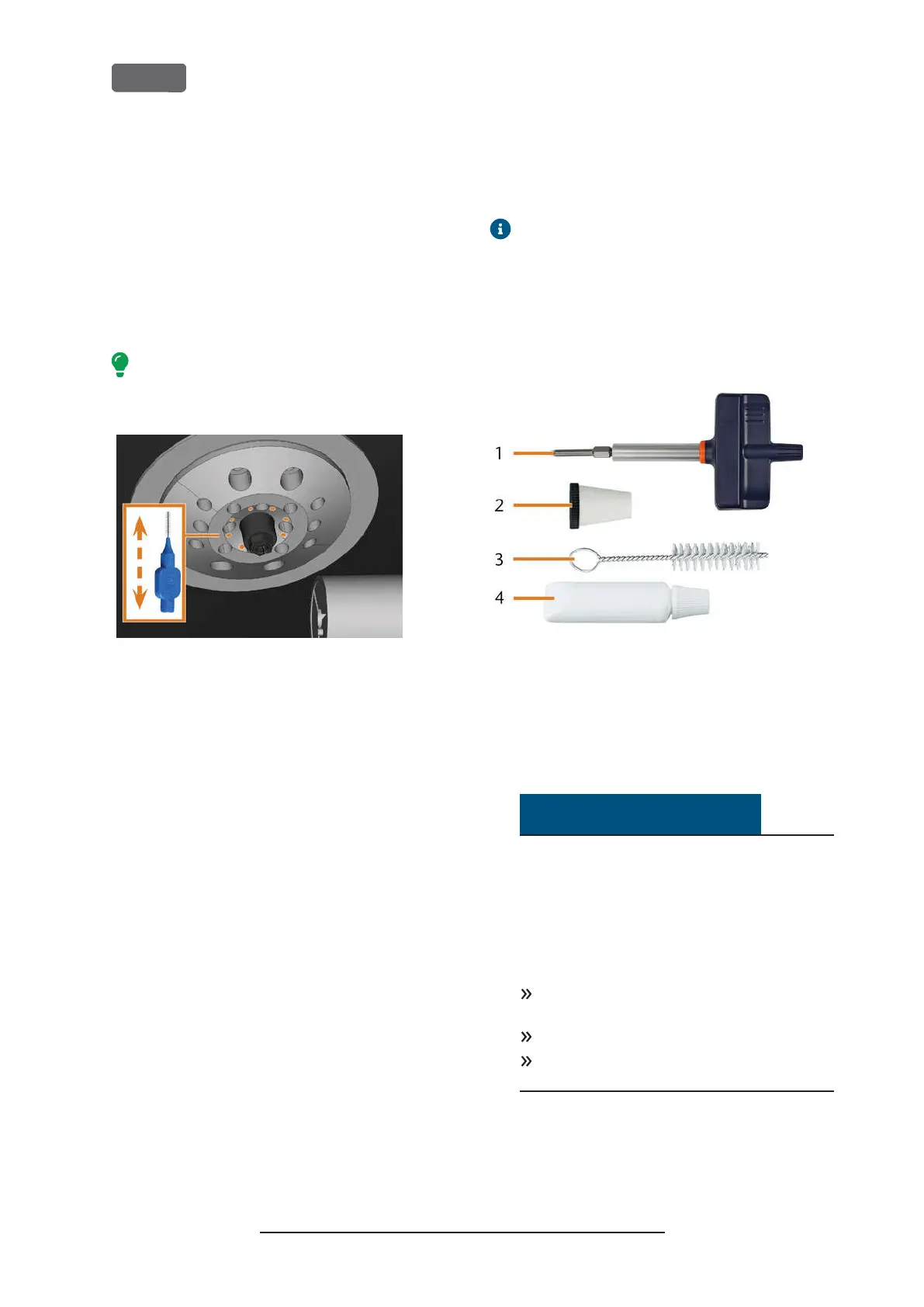

1.

Have the interdental brush ready.

2.

Open the working chamber door.

3.

Clean the ring of 8 holes in the inner area of the

nozzle plate. For this, move the interdental brush

up and down.

If necessary, apply some water with a cleaning

agent and let it sit for some minutes.

F

IG

. 74 – C

LEANING THE NOZZLE PLATE

;

NOZZLES MARKED ORANGE

Cleaning the collet chuck of the

blank holder

The grease for the collet chuck of the spindle

and for the collet chuck of the blank holder is

the same item.

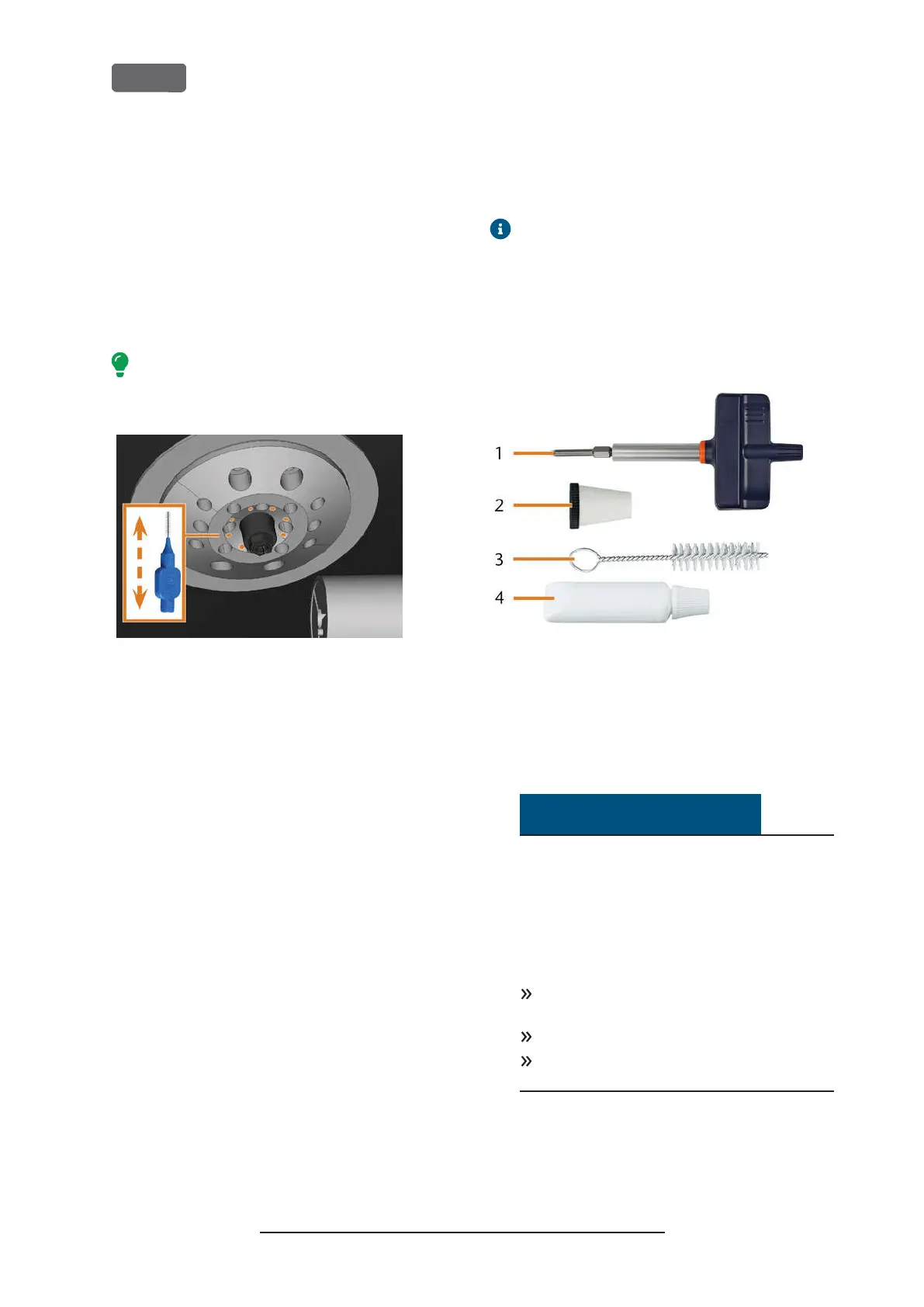

1.

Have ready:

n

Blank holder service set

n

Collet chuck grease

F

IG

. 75 – B

LANK HOLDER SERV ICE SET

1.

Torque screwdriver (1.8Nm)

2.

Cleaning cone

3.

Cleaning brush

4.

Tube of collet chuck grease

NOTICE

Damaging of the block holder when

using the wrong torque screwdriver or

performing the maintenance with the

machine switched off

If you use a torque screwdriver other than the one

included in the scope of delivery, or if you

perform the maintenance with the machine

switched off, the block holder can get damaged.

Ensure that the machine is switched on during

the entire duration of the repair.

Only use the provided torque screwdriver.

Ensure that you apply a maximum torque of

1.8Nm.

2.

Switch on the machine at the main power switch.

3.

Open the working chamber door.

Original Operating Instructions:Z4

Version: 12/5/2018

Z4 – Maintenance and do-it-yourself

EN 60

Loading...

Loading...