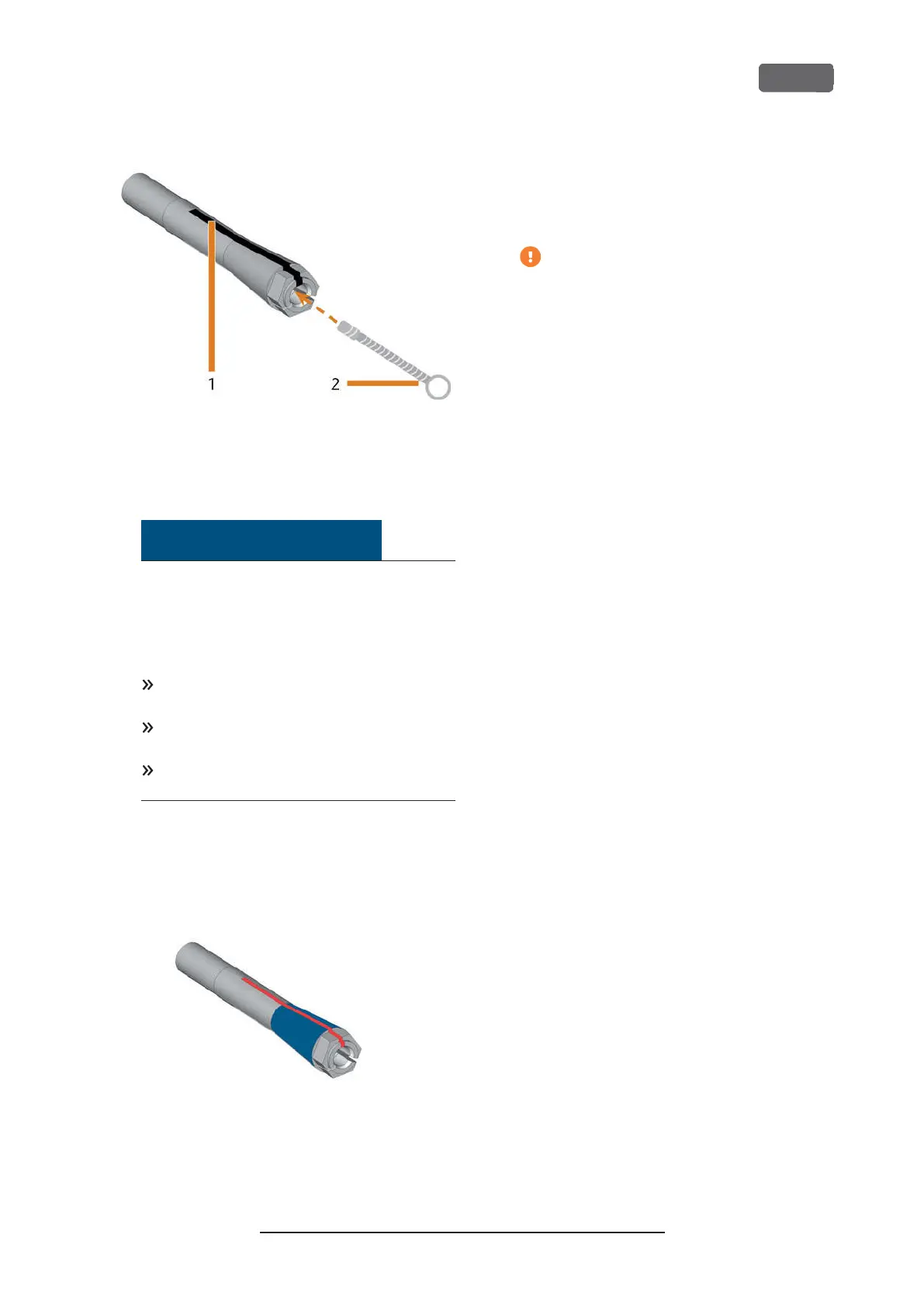

F

IG

. 72 – C

LEANING THE COLLET CHUCK

1.

Longitudinal slot

2.

Cleaning brush

NOTICE

Damaging of the spindle when using

the wrong grease or applying the

grease incorrectly

If you use unsuitable grease or if grease gets into

the longitudinal slots of the collet chuck, the

machine may get damaged.

Ensure that no grease gets into the lon-

gitudinal slots of the collet chuck.

Only use a very small, about pinhead-size

amount of the grease.

Only use the provided grease of the service

set.

9.

Put a small amount of the collet grease on the

index finger and smear it with the thumb.

10.

Apply the smeared collet grease to the flanks of

the collet chuck.

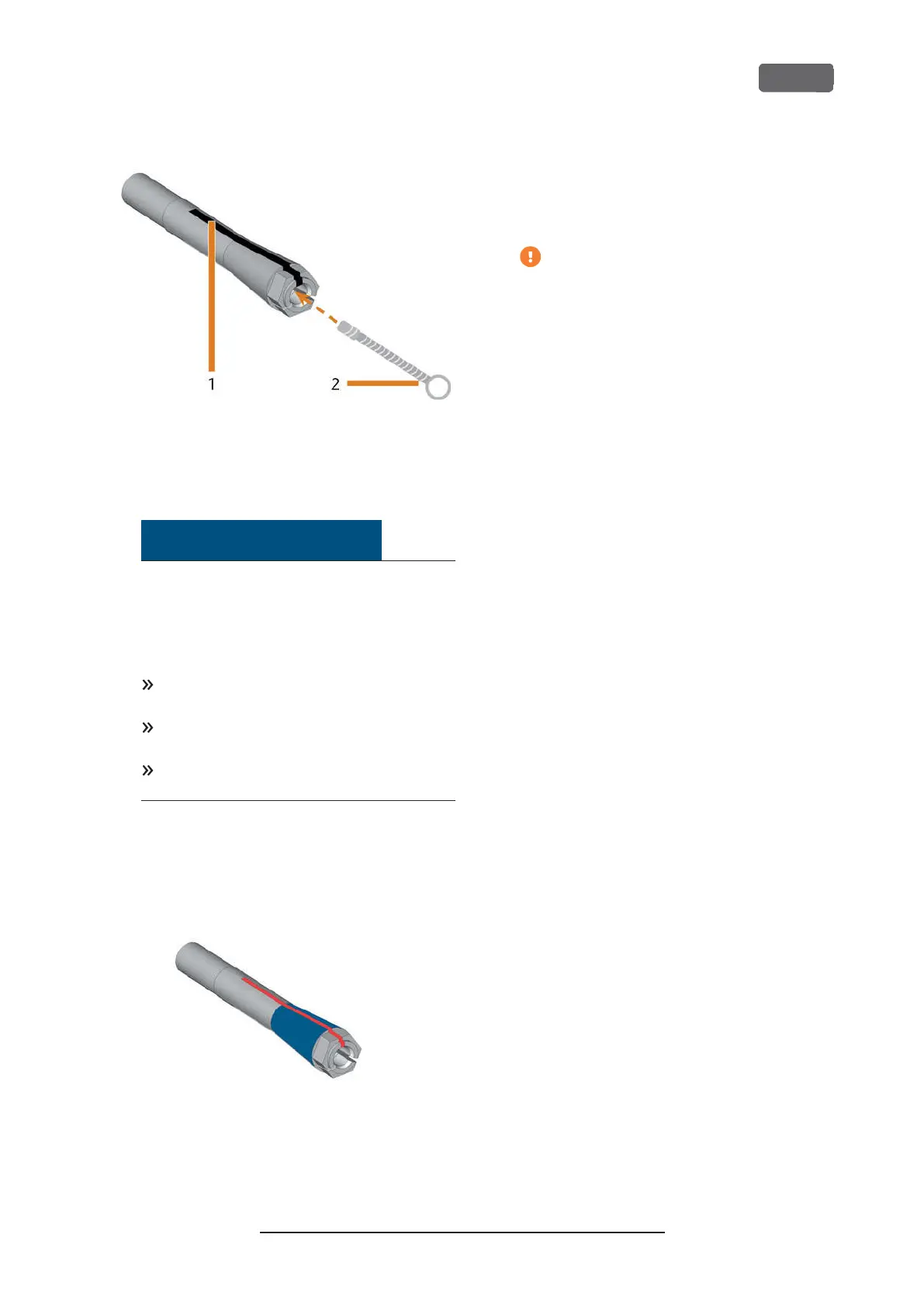

F

IG

. 73 – G

REASING THE COLLET CHUCK

;

SURFACE IN WHICH

GREASE IS TO BE APPLIED IS MARKED IN BLUE

;

SLOT THAT MAY NOT

BE GREASED IS MARKED IN RED

11.

Insert the measuring pin into the collet chuck

with one hand and keep holding it. Screw the col-

let chuck with the knurled nut in your other hand

tightly into the spindle.

Turn the knurled nut as far as you can so

that the collet chuck is properly seated in

the spindle. Otherwise rotational imper-

fections can occur during operation which

will worsen your processing results

12.

Remove the measuring pin from the collet chuck

and store it together with the other components

of the spindle service set.

13.

Clean the nozzle plate.

Z4 – Maintenance and do-it-yourself

EN 59

Original Operating Instructions:Z4

Version: 12/5/2018

Loading...

Loading...