4.

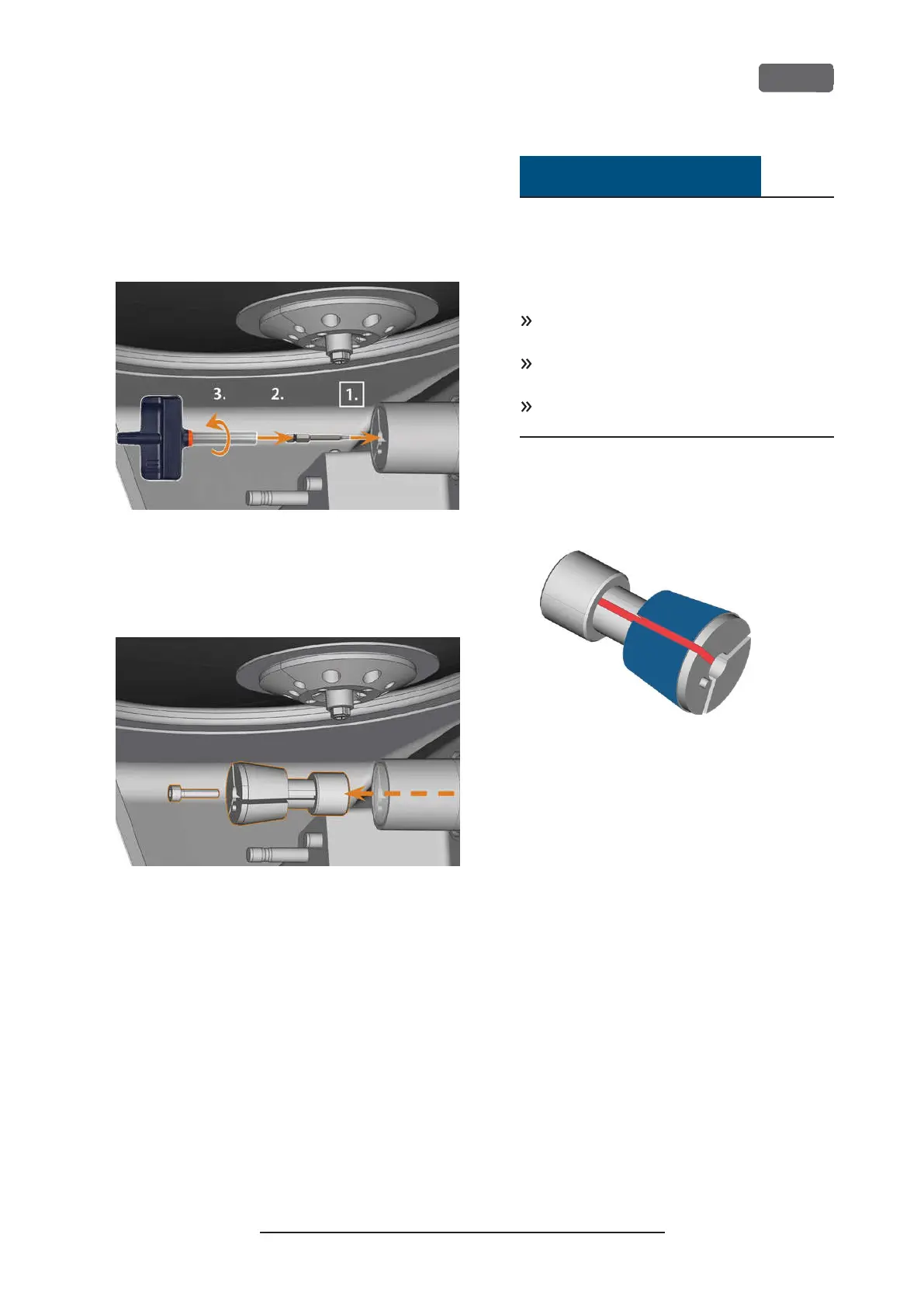

Insert the bit of the torque screwdriver into the

collet chuck and hold it in place.

5.

Put the torque screwdriver on the bit and

unscrew the screw by twisting the torque screw-

driver.

F

IG

. 76 – L

OOSENING THE SCREW OF THE BLANK HOLDER COLLET

CHUCK

6.

Remove the collet chuck and the screw from the

blank holder. Put both items aside within reach.

F

IG

. 77 – R

EMOVING THE COLLET CHUCK FROM THE BLANK HOLDER

7.

Clean the inner cone of the blank holder with the

cleaning cone of the service set.

8.

Clean the collet chuck with the brush of the ser-

vice set.

NOTICE

Damaging of the collet chuck when

using the wrong grease or applying the

grease incorrectly

If you use unsuitable grease or if grease gets into

the longitudinal slots of the collet chuck, the

machine may get damaged.

Ensure that no grease gets into the lon-

gitudinal slots of the collet chuck.

Only use a very small, about pinhead-size

amount of the grease.

Only use the provided grease of the service

set.

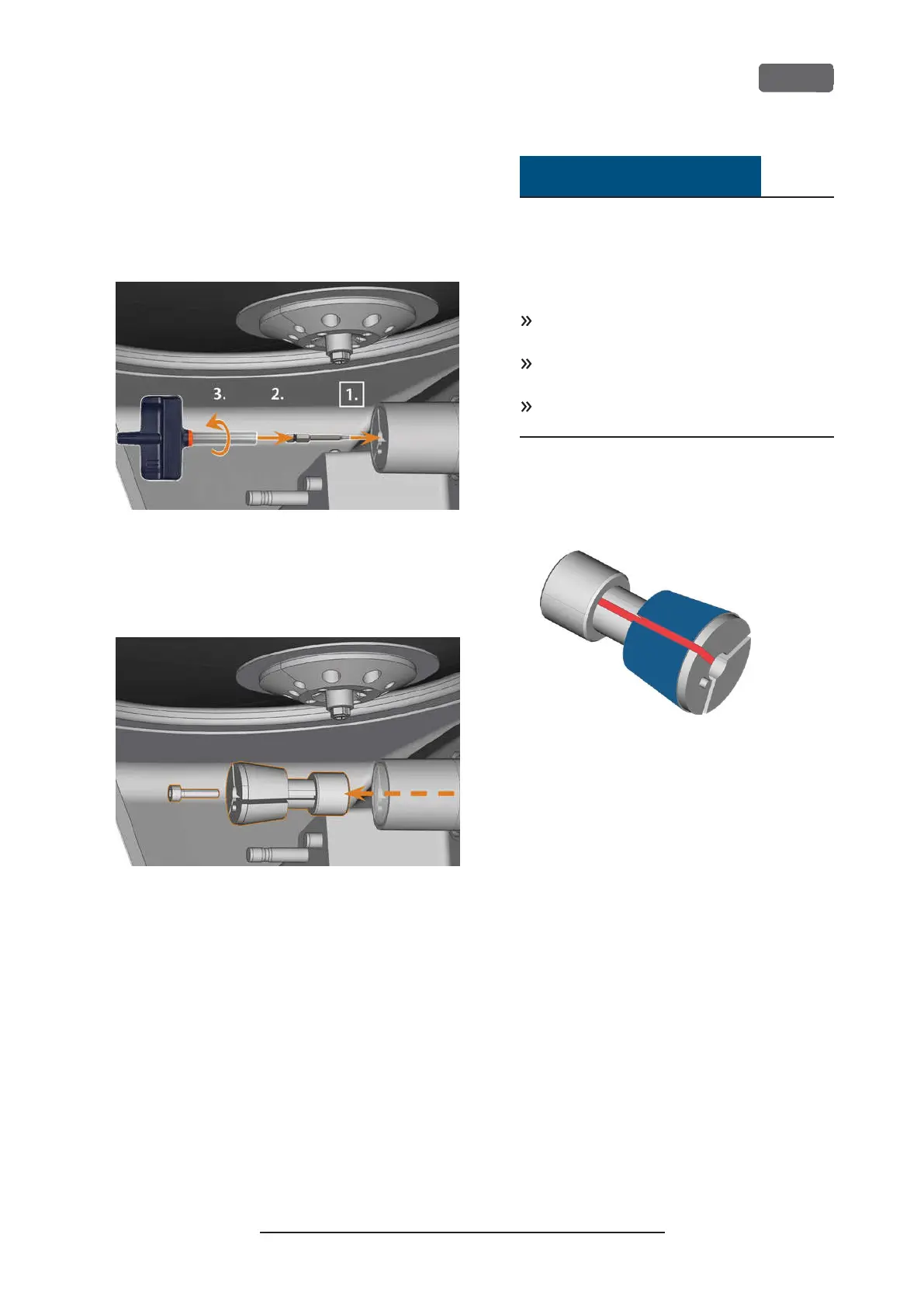

9.

Clean the outside of the collet chuck.

10.

Grease the collet chuck. Apply the grease only to

the conical surface of the collet chuck.

F

IG

. 78 – G

REASING THE COLLET CHUCK

;

SURFACE IN WHICH

GREASE IS TO BE APPLIED IS MARKED IN BLUE

;

SLOT THAT MAY NOT

BE GREASED IS MARKED IN RED

11.

Check the condition of the fixing screw and

replace it by a spare screw if necessary.

12.

Push the collet chuck with fixing screw into the

blank holder as far as you can. Twist the collet

chuck until it snaps in place and is properly

seated. Depending on the position you may

need to twist it up to 360°.

Z4 – Maintenance and do-it-yourself

EN 61

Original Operating Instructions:Z4

Version: 12/5/2018

Loading...

Loading...