wallPen E2 | User Manual

106

Service

9 Service

9.1 Hardware Maintenance

9.1.1

Care of the Vertical Axis

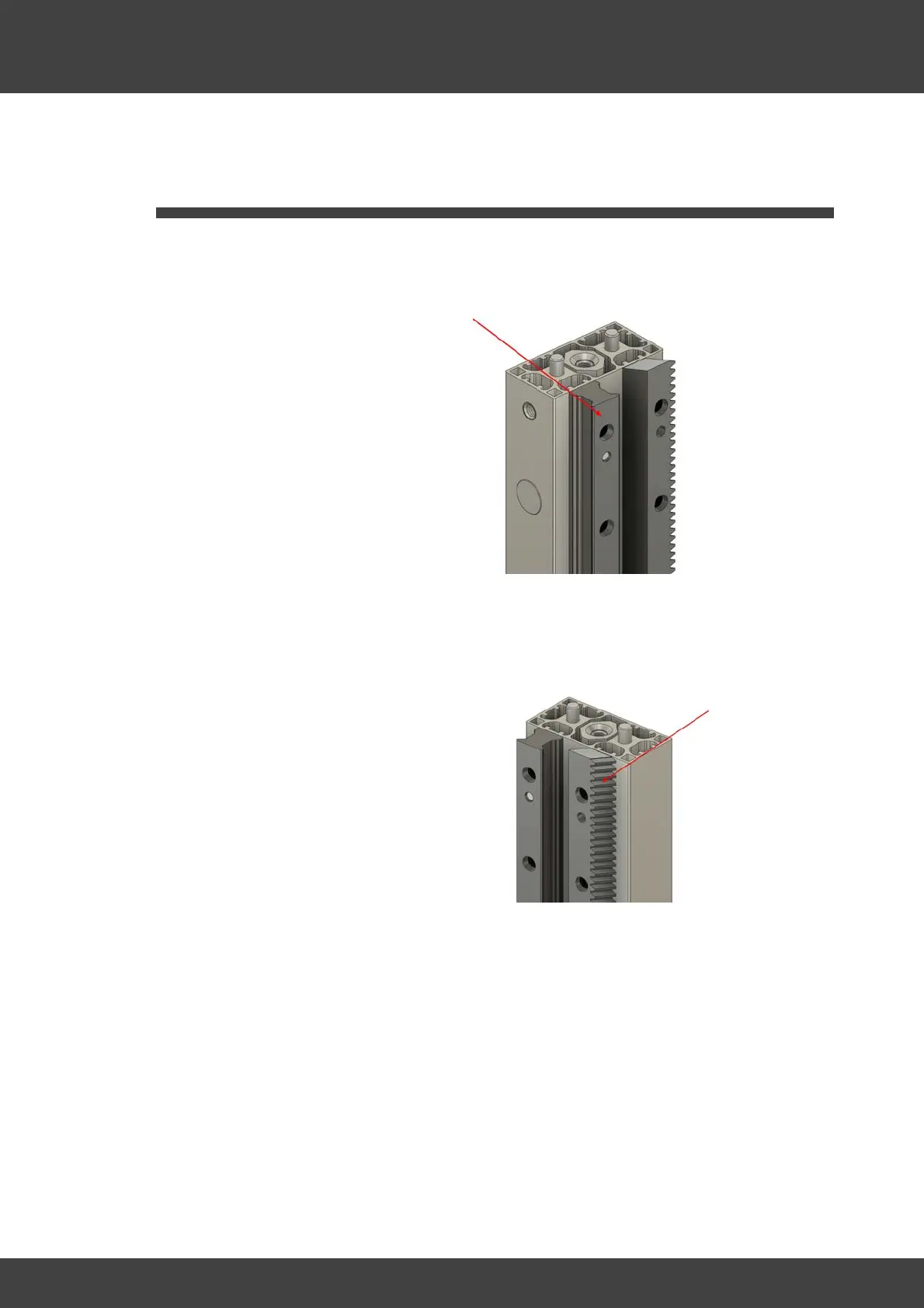

The linear profile of the vertical axis

should be wiped briefly with an oil-

moistened cloth (conventional machine

oil) along its entire length after each

use of the printer so that a thin film of

oil forms on the metal. This effectively

prevents dirt or rust from accumulating

on the rail or slide over time.

9.1.2

Care of the Toothed Rack

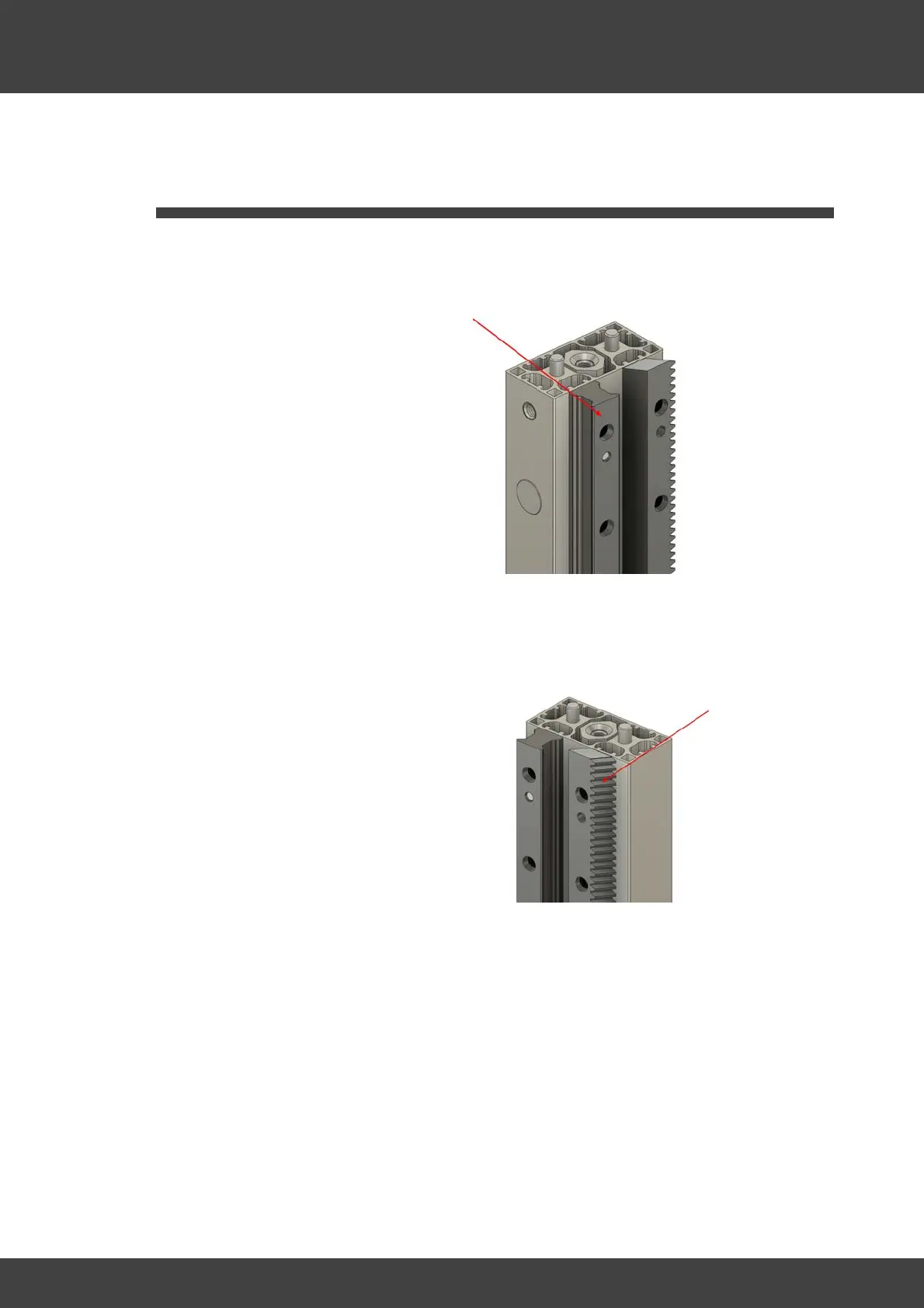

The gear rack should never be

greased, as the grease presses into

the rear flanks of the teeth and can

have a very negative effect on the

clean running of the gear wheel.

Instead, clean the rack from time to

time - especially in the area of the rear

flanks - with a thin wooden stick or

cloth and oil the rack thinly with an oil-

soaked cloth (conventional machine oil)

to prevent rust.

9.1.3

Care of the Linear Slide

The linear slide is a high-precision system in which 4 chains of ground steel balls run to

guide the slide on the profile. The system must be greased after a running distance of

2000 km or after 12 months - whatever comes first - to avoid abrasion and friction and

to ensure smooth running. Only use the grease supplied by wallPen and the grease gun

supplied.

It is best to grease the system when the printer is disassembled. This is the best way to

reach the screw for the grease nipple and to apply the grease gun stably.

Loading...

Loading...