CRANKCASE

5-78

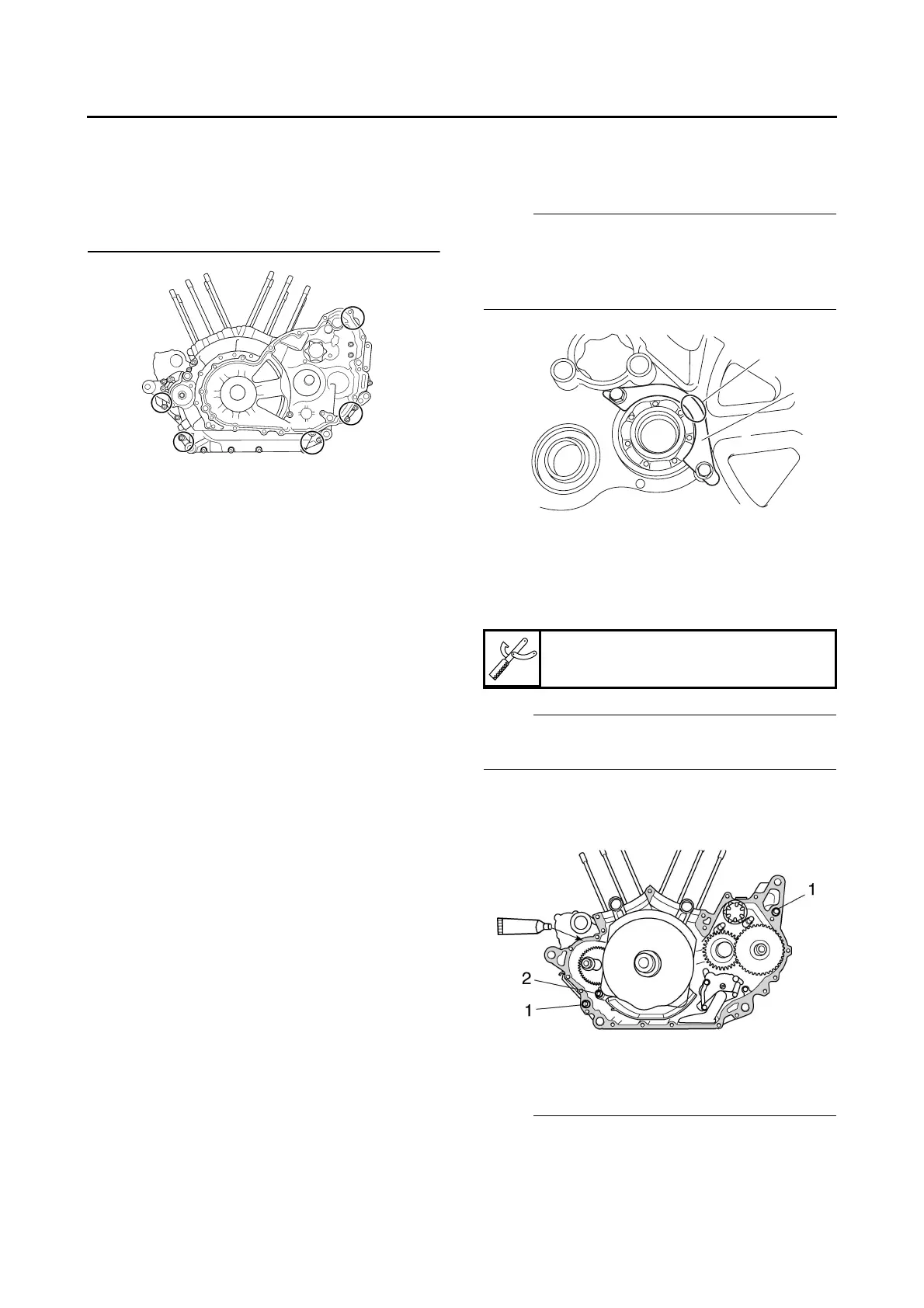

• Tap on one side of the crankcase with a

soft-face hammer. Tap only on reinforced

portions of the crankcase, not on the crank-

case mating surfaces. Work slowly and

carefully and make sure the crankcase

halves separate evenly.

EAS25580

CHECKING THE CRANKCASE

1. Thoroughly wash the crankcase halves in a

mild solvent.

2. Thoroughly clean all the gasket surfaces and

crankcase mating surfaces.

3. Check:

• Crankcase

Cracks/damage → Replace.

• Oil delivery passages

Obstruction → Blow out with compressed air.

ET5YU1022

CHECKING THE BEARINGS AND OIL SEAL

1. Check:

• Bearings

Clean and lubricate the bearings, then rotate

the inner race with your finger.

Rough movement → Replace.

• Oil seal

Damage/wear → Replace.

EAS25590

CHECKING THE OIL PIPE

1. Check:

• Oil pipe

Damage → Replace.

Obstruction → Wash and blow out with com-

pressed air.

EAS25610

CHECKING THE OIL PUMP DRIVE

1. Check:

• Oil pump drive gear

• Oil pump driven gear

Chips/pitting/roughness/wear → Replace the

defective part(s).

ET5YU1023

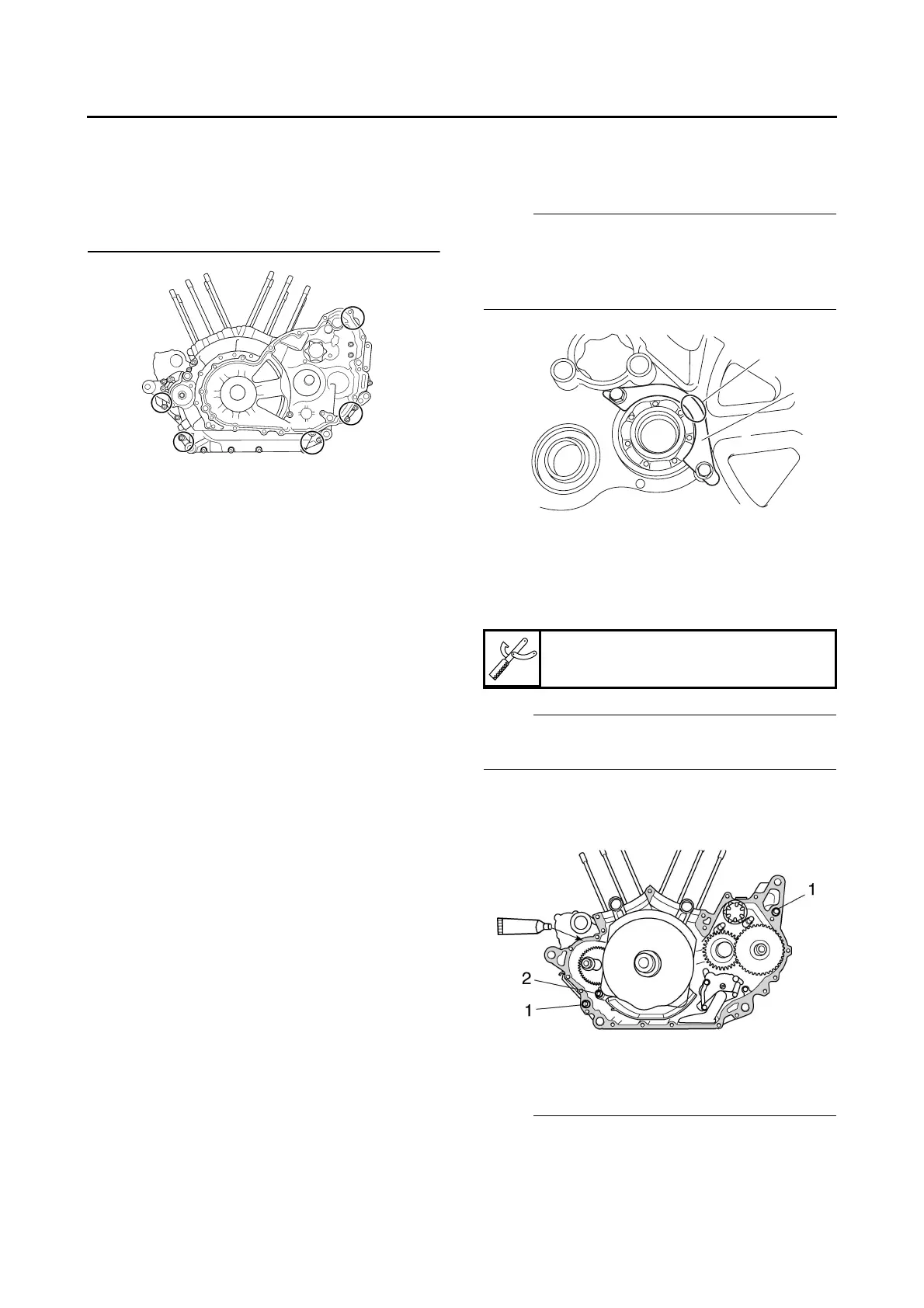

INSTALLING THE BEARING RETAINER

1. Install:

• Bearing retainer “1”

NOTE:

• Install the bearing retainer “1” with its “OUT”

mark “a” facing outward.

• Apply locking agent (LOCTITE

®

) to the threads

of the bearing retainer bolt.

EAS25690

ASSEMBLING THE CRANKCASE

1. Apply:

• Sealant

(onto the crankcase mating surfaces)

NOTE:

Do not allow any sealant to come into contact

with the oil gallery.

2. Install:

• Dowel pins “1”

• Joint pipe “2”

3. Install:

• Left crankcase

(onto the right crankcase)

NOTE:

• Turn the shift drum segment “1” to the position

shown in the illustration. In this position, the

shift drum segment’s teeth will not contact the

crankcase during crankcase installation.

Yamaha bond No. 1215

90890-85505

OUT

a

1

Loading...

Loading...