3. Troubleshooting

115

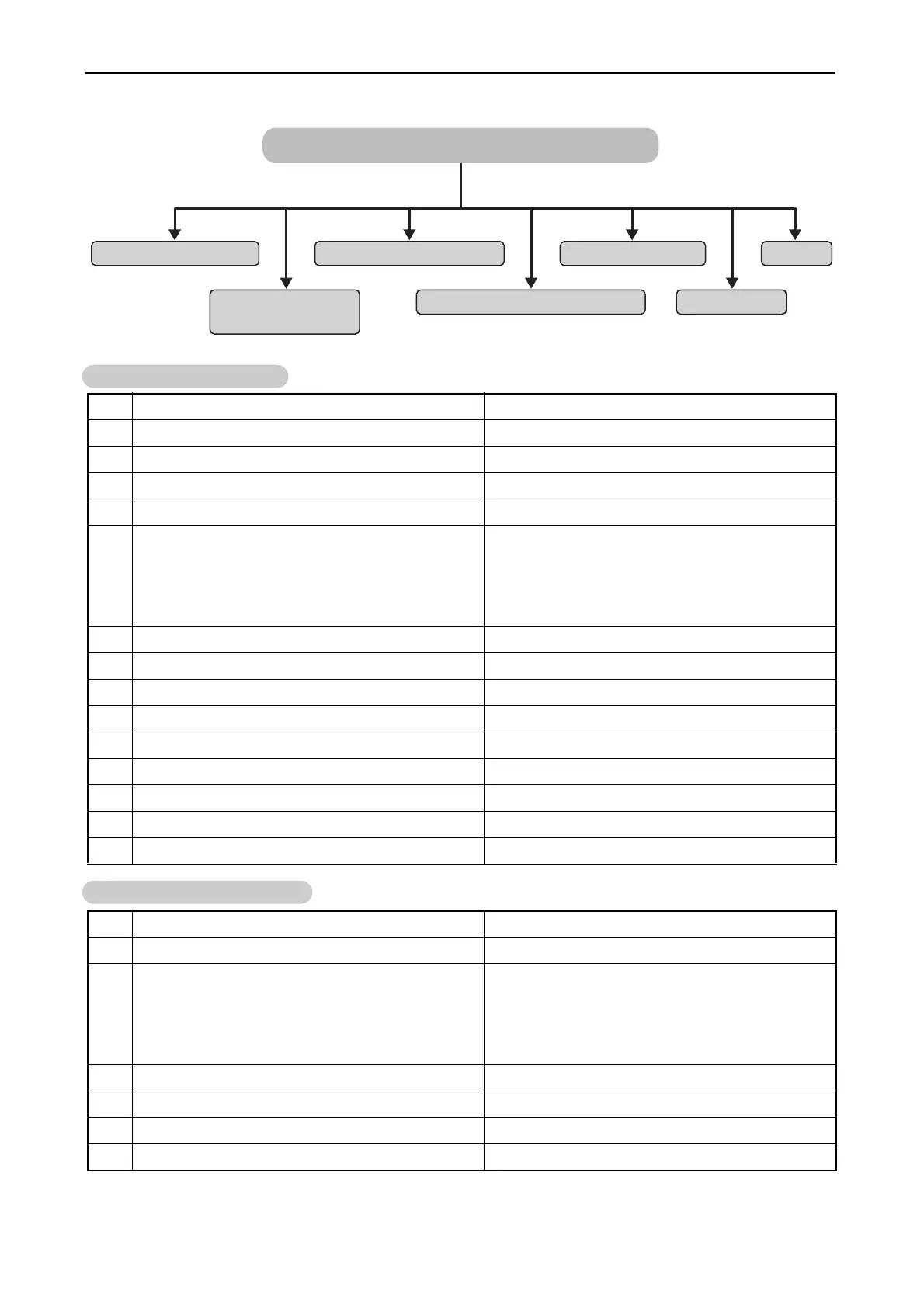

(I) Drop in intake pressure

(II) Increased intake pressure

No. Cause and effect Countermeasure

1 Dirty filter. Clean.

2 Dirty guide vane at outlet of compressor. Clean.

3 Leak from intake piping. Repair.

4 Leak of exhaust gas. Repair.

5 High intake air temperature. (a) Make thermal insulation of exhaust pipe

complete.

(b) Intake the air from outside the combustion

chamber.

(c) Clean intercooler.

6 Drop in air pressure in engine room. Open the door or provide atmosphere intake duct.

7 Broken seal ring. Replace.

8 Broken turbine impeller. Replace.

9 Broken nozzle ring. Replace.

10 Dirty turbine impeller. Clean.

11 Clogged nozzle. Clean.

12 Clogged exhaust pipe. Clean.

13 Too high back pressure. Clean or change the piping.

14 Wrong reading of pressure gage. Replace.

No. Cause and effect Countermeasure

1 Exhaust gas leak. Carry out remote of T/C.

2 Failure in fuel injection system. (a) Inspect and adjust the injection timing.

(b) Disassemble and inspect the injection pump,

and repair or replace faulty parts.

(c) Disassemble and inspect the injection valve,

and repair or replace faulty parts.

3 Deformed turbine nozzle. Replace.

4 Dirty turbine side. Clean.

5 Increase in load (over loading). Reduce the load.

6 Wrong reading of pressure gage. Replace.

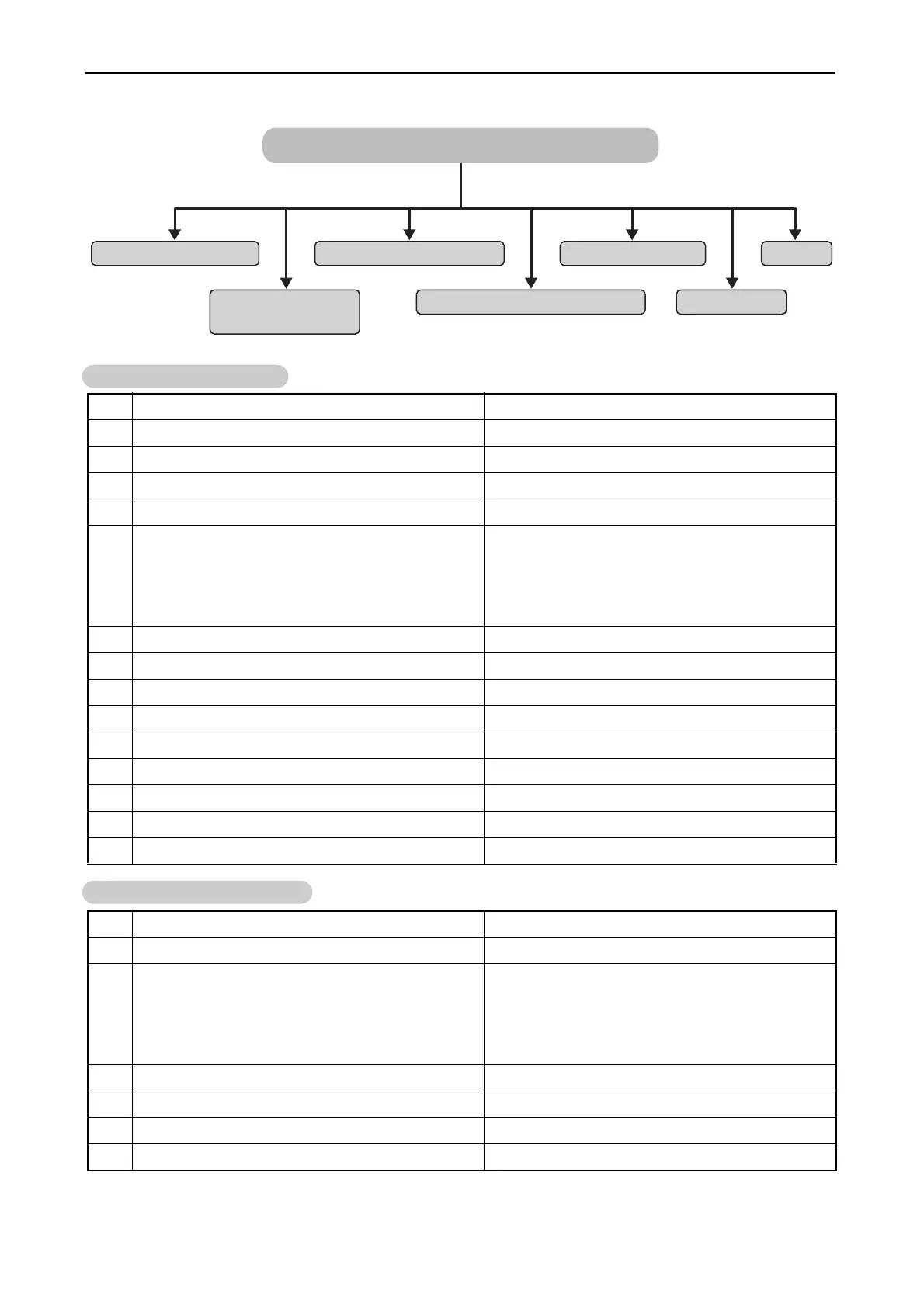

TURBOCHARGER BREAKDOWN

(I) Drop in intake pressure (III) Abnormal vibration (IV) Noise(II) Increased intake pressure

(V)Quick contamination

of lubrication oil

(VII) Others(VI) Pulsation of intake air pressure

Loading...

Loading...