3. Troubleshooting

120

3.4 Troubleshooting by

measuring compression

pressure

Compression pressure drop is one of major causes

of increasing blowby gas (lubricating oil contamina-

tion or increased lubricating oil consumption as a

resultant phenomenon) or starting failure. The com-

pression pressure is affected by the following factors:

1) Degree of clearance between piston and

cylinder.

2) Degree of clearance at intake/exhaust valve

seat.

3) Gas leak from nozzle gasket or cylinder head

gasket.

In other words, the pressure drops due to

increased parts wear and reduced durability

resulting from long use of the engine.

A pressure drop may also be caused by scratched

cylinder or piston by dust entrance from the dirty

air cleaner element or worn or broken piston ring.

Measure the compression pressure to diagnose

presence of any abnormality in the engine.

(1) Compression pressure measurement

method

1) After warming up the engine, remove the fuel

injection pipe and valves from the cylinder to

be measured.

2) Crank the engine before installing the

compression gage adapter.

a) Perform cranking with the stop handle at the

stop position (no injection state).

b) See 4.2.3(2) in Chapter 4 for the

compression gage and compression gage

adapter.

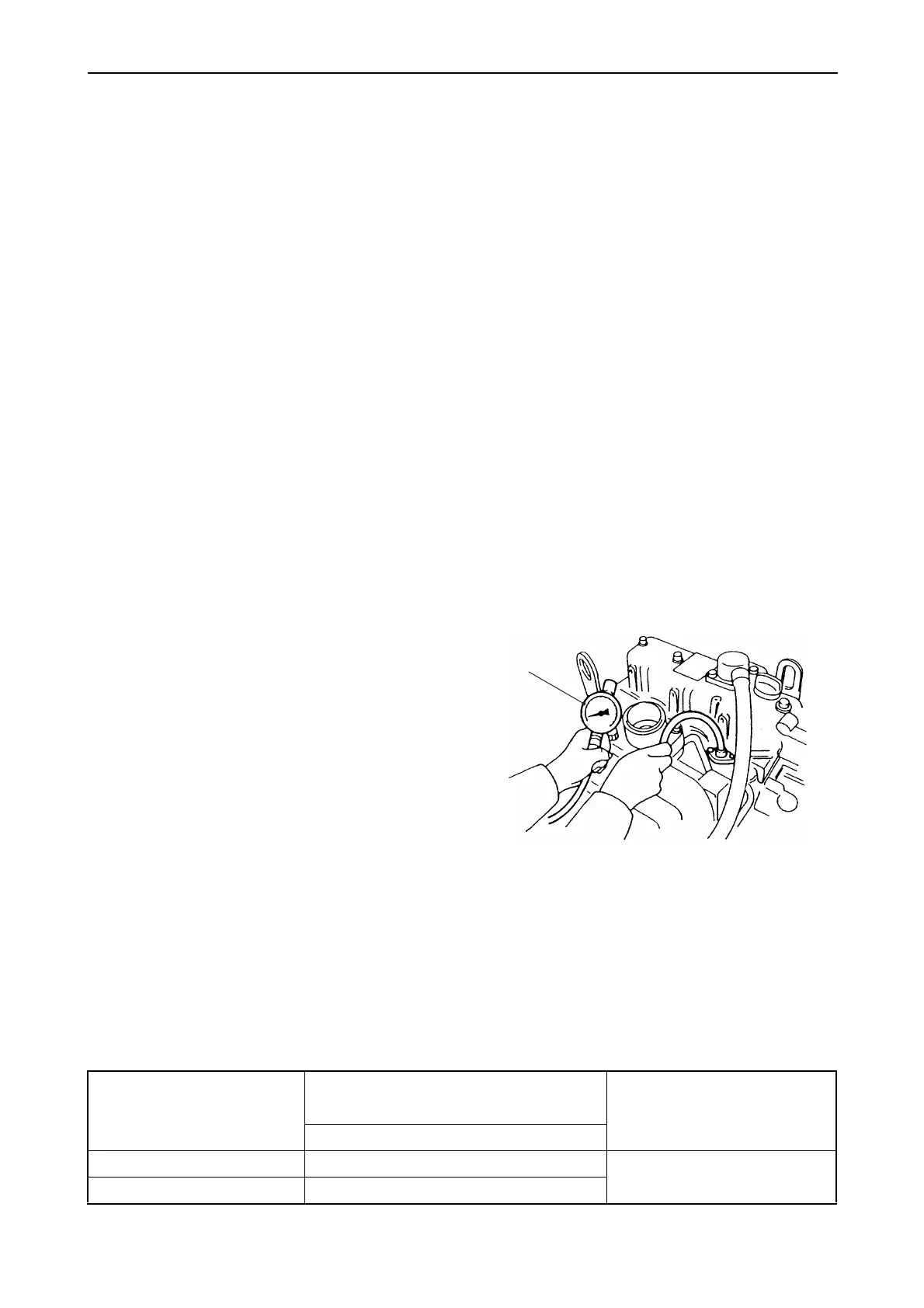

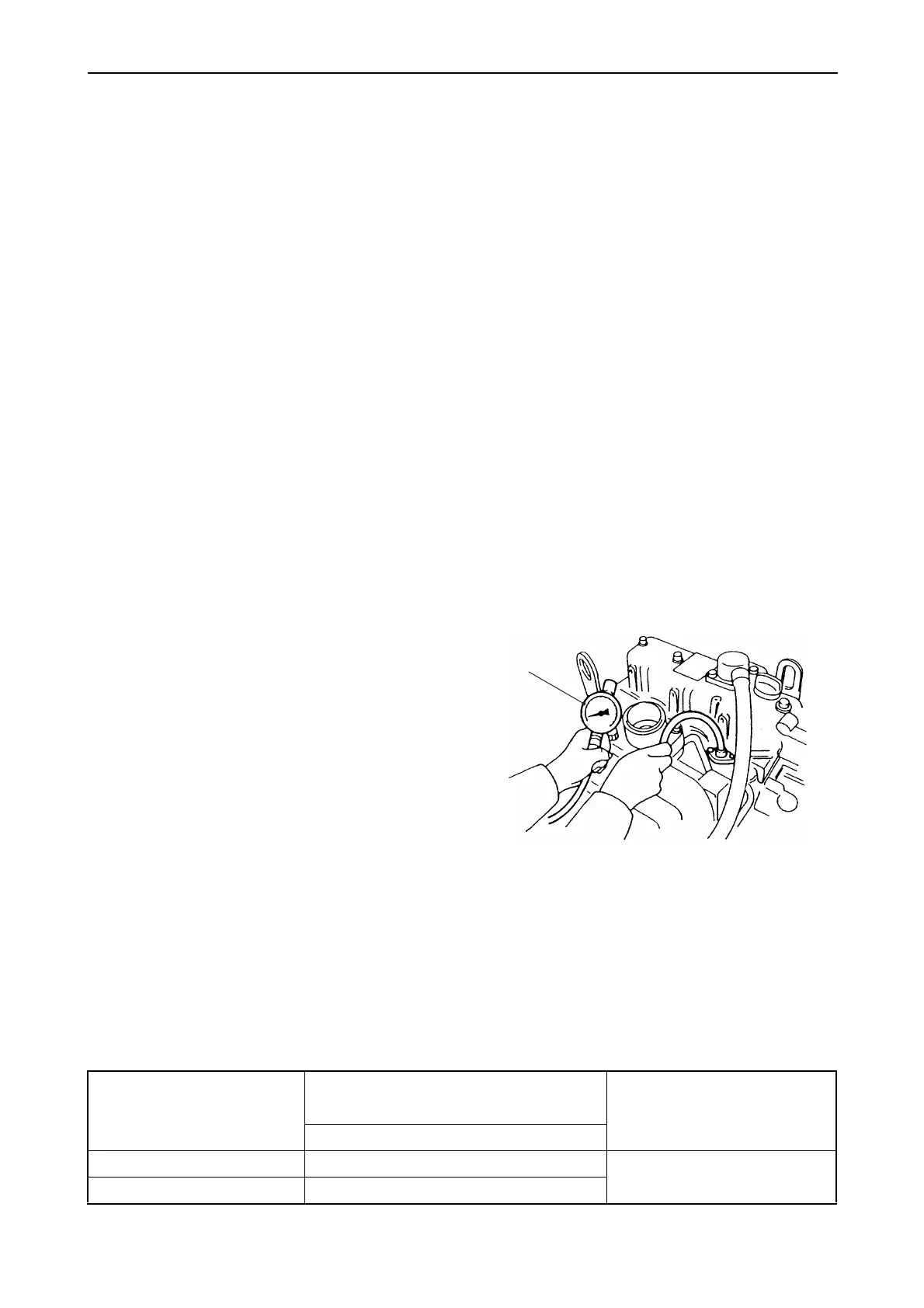

3) Install the compression gage and

compression gage adapter at the cylinder to

be measured.

a) Never forget to install a gasket at the tip end

of the adapter.

4) With the engine set to the same state as in

2)a), crank the engine by the starter motor

until the compression gage reading is

stabilized.

(2) Standard compression pressure

Engine compression pressure list (reference value)

Model

Compression pressure at 250 min

-1

MPa (kgf/cm

2

)

Deviation among cylinders

MPa (kgf/cm

2

)

Standard

3JH4E/ 4JH4E/ 4JH4-TE 3.4

±

0.1 (35

±

1)

0.2 to 0.3 (2 to 3)

4JH4-HTE 3.2

±

0.1 (32

±

1)

Compression

gage

010638-00SE

Loading...

Loading...