5. Inspection and servicing of basic engine parts

202

5.4.2 Crank pin metal

(1) Checking crank pin metal

Check for flaking, melting or seizure on the

contact surface of the crank pin metal.

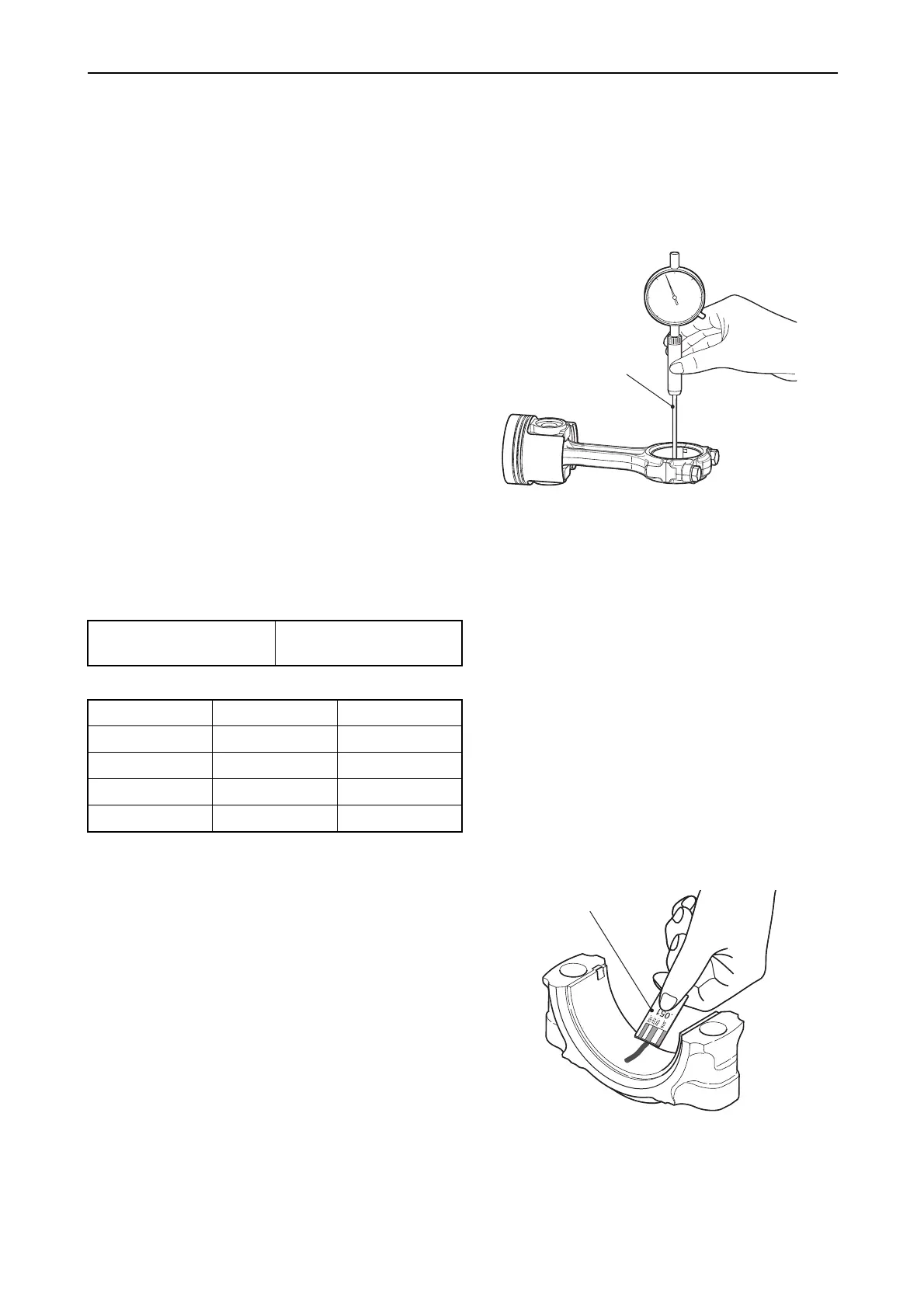

(2) Measuring crank pin oil clearance

Measure the crankpin outside diameter and

the crank pin metal inside diameter. Calculate

the oil clearance from the measured values.

(Refer to 5.5.1(3) for measuring the crank pin

outside diameter.)

Replace the crank pin metal if the oil

clearance becomes about the limit dimension

of the below table.

Correct by grinding if unevenly wear,

roundness exceeding the limit or insufficient

outside diameter is found. Also use an

undersized metal if necessary.

[NOTICE]

When measuring the inside diameter of the

rod big end, install the crank pin metal in the

rod big end not to mistake the top and

bottom of the metals and tighten the rod

bolts by the standard torque.

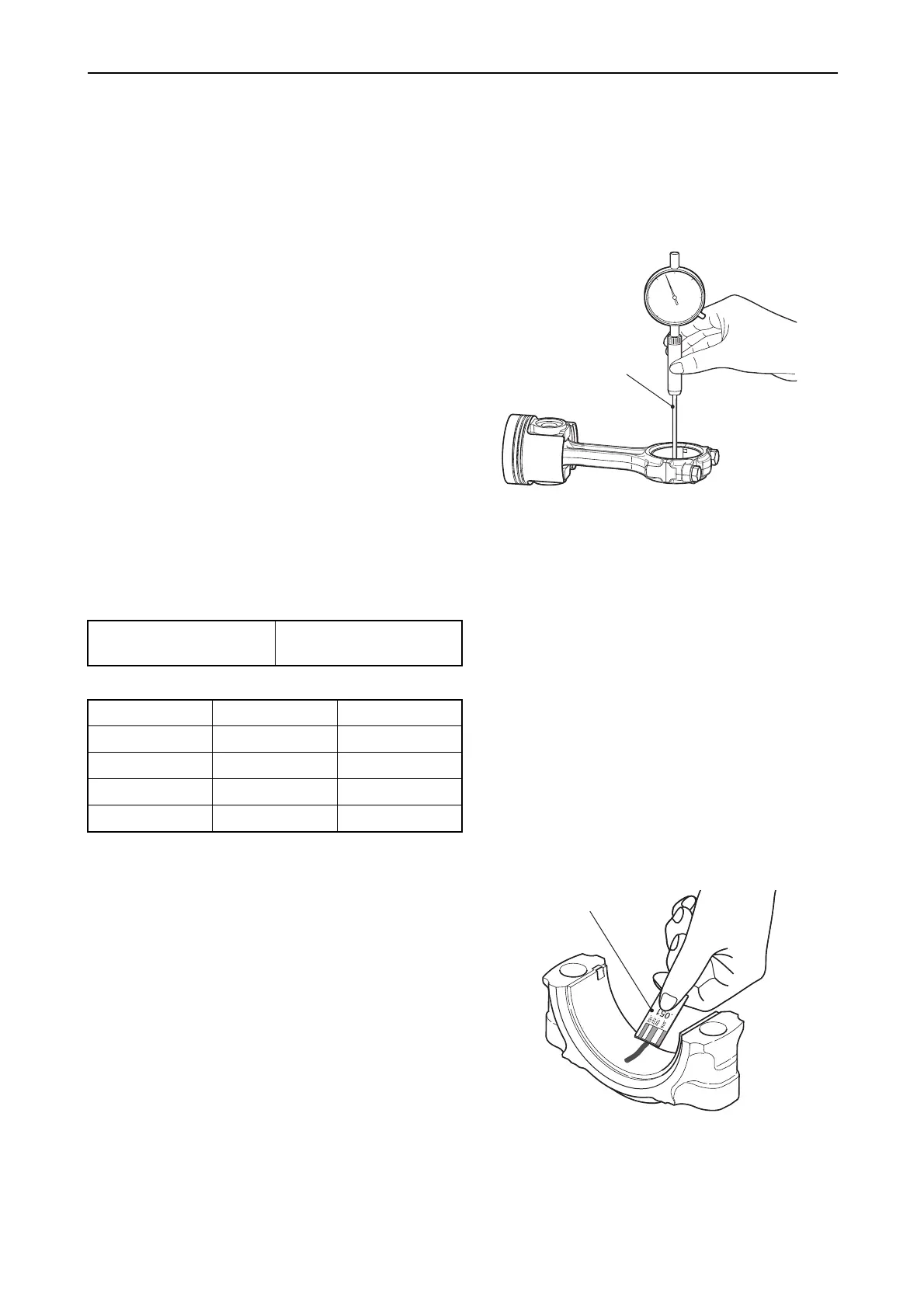

• Other procedure of measuring crank pin oil

clearance

1) Use the press gauge (Plasti-gauge) for

measuring the oil clearance of the crank pin.

2) Mount the connecting rod on the crank pin

(tighten to specified torque).

3) Remove the connecting rod and measure the

broken plasti-gauge with measuring paper.

Nm (kgf•m)

Rod bolt tightening

torque

44.1-49.1

(4.50-5.01)

mm

Item Standard Limit

Rod metal I.D. 48.000-48.026 -

Crankpin O.D. 47.952-47.962 47.902

Metal thickness 1.492-1.500 -

Clearance 0.038-0.074 0.150

Cylinder gauge

008727-01E

Plasti-gauge

008286-01E

Loading...

Loading...