9. Coolant system

275

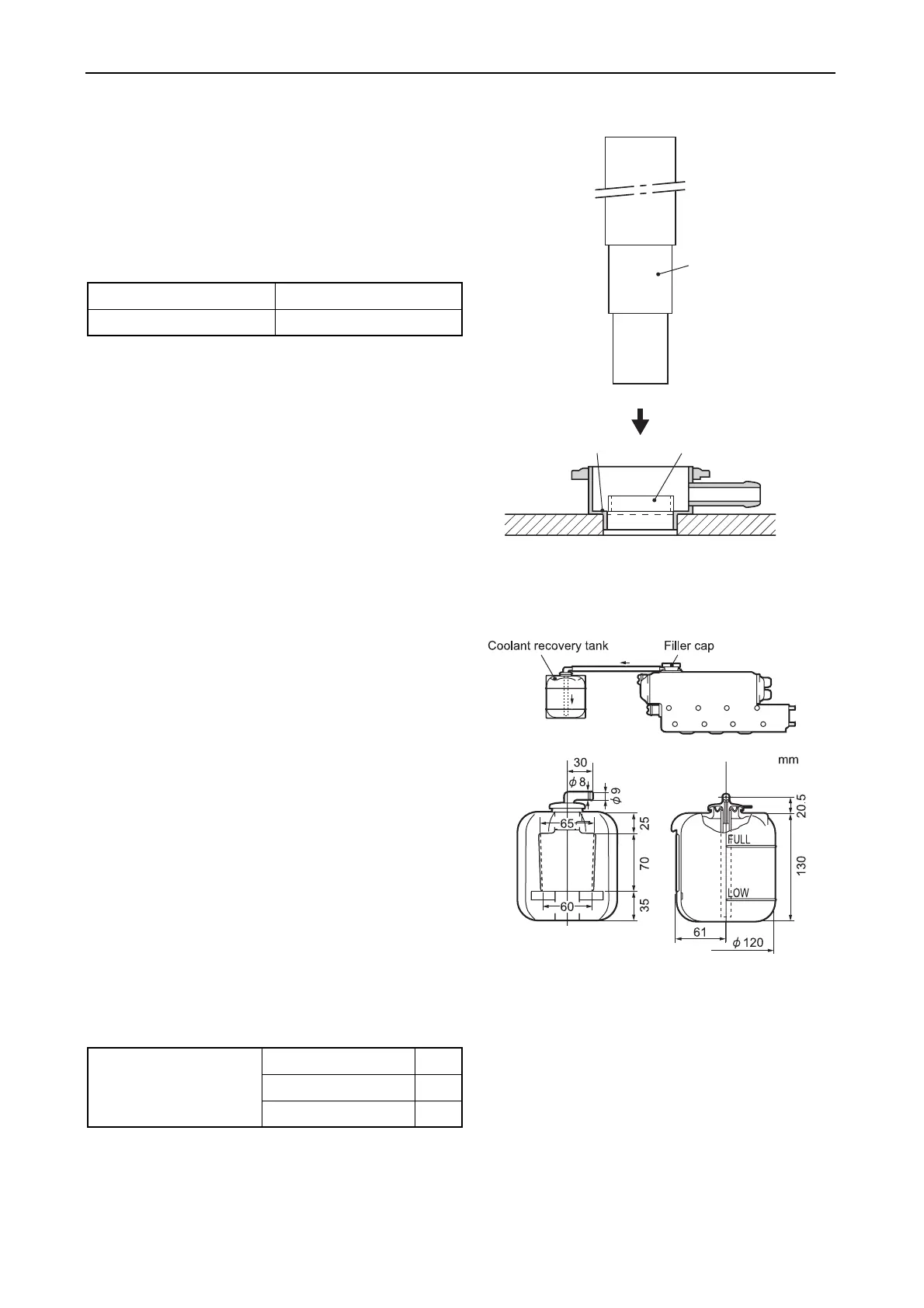

4) To fix the filler neck on the fresh water cooler,

press the small copper tube inside the filler

neck with the special tool.

Note:

The top of this tube should be under the

sealing surface of the filler neck for the

pressure cap.

5) Fit the pressure cap on the filler neck.

Refer to 4.2.2 for tool 1 and tool 2.

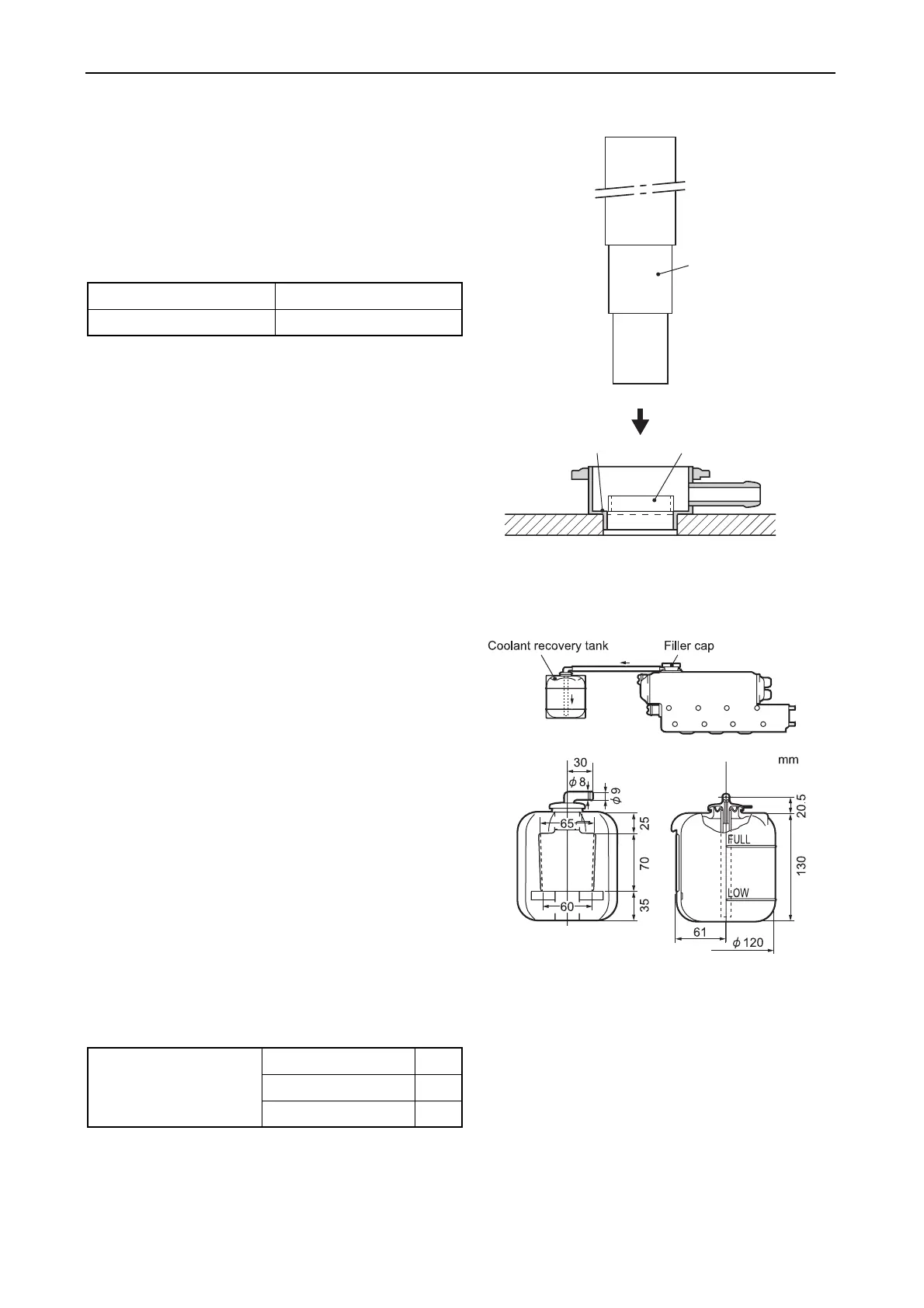

9.5.5 Function of the coolant recovery

tank

The pressure valve opens to discharge steam

when the steam pressure in the fresh water tank

exceeds 82-109 kPa (0.84-1.11 kgf/cm

2

).

This consumes water. The coolant recovery tank

maintains the water level by preventing this

discharge of water.

The steam discharged into the coolant recovery

tank condenses into watch, and the water level in

the tank rises.

When the pressure in the fresh water system

drops below the normal value, the water in the

coolant recovery tank is sucked back into the fresh

water tank to raise the water back to its original

level.

The coolant recovery tank facilitates long hours of

operation without water replacement and

eliminates the possibility of burns when the steam

is ejected from the filler neck because the pressure

cap does not need to be removed.

9.5.6 Specifications of coolant recovery

tank

Filler neck Part No. Copper tube Part No.

129673-44110 129673-44150

Capacity of

coolant recovery tank

Overall capacity 1.3 L

Full-scale position 0.8 L

Low-scale position 0.2 L

001588-00E

Press the copper tube

in the filler neck

Copper tube

Tool 2

Sealing surface

001589-01

Loading...

Loading...