5. Inspection and servicing of basic engine parts

208

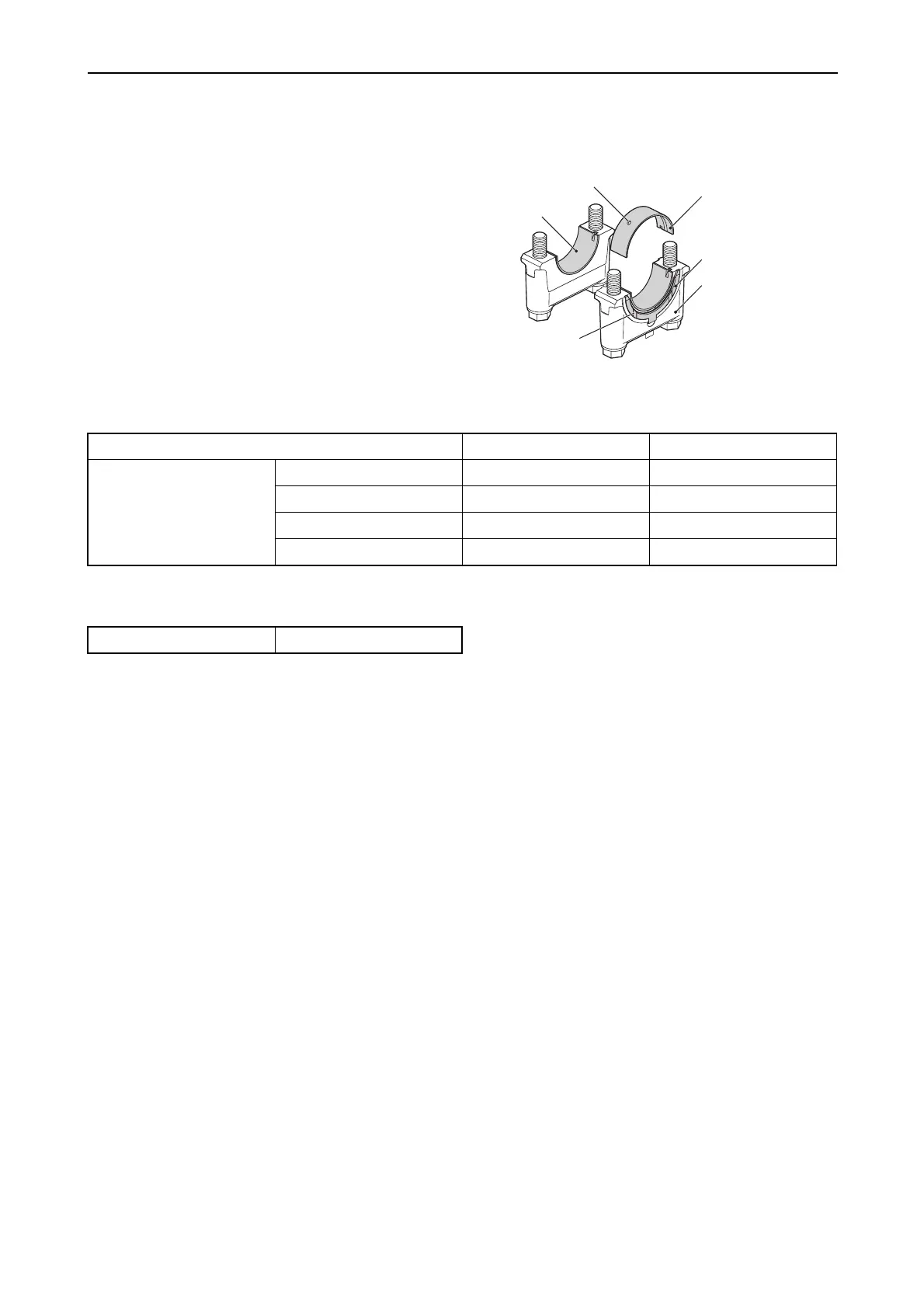

5.5.2 Main bearing

(1) Inspecting the main bearing

Check for flaking, seizure or burning of the

contact surface and replace if necessary.

(2) Measuring the inner diameter of metal

Tighten the cap to the specified torque and

measure the inner diameter of the metal.

Note:

When assembling the bearing cap, keep the

following in mind.

1) The lower metal (cap side) has no oil groove.

2) The upper metal (block side) has an oil

groove.

3) Check the cylinder block alignment number.

4) The “FW” on the cap lies on the flywheel

side.

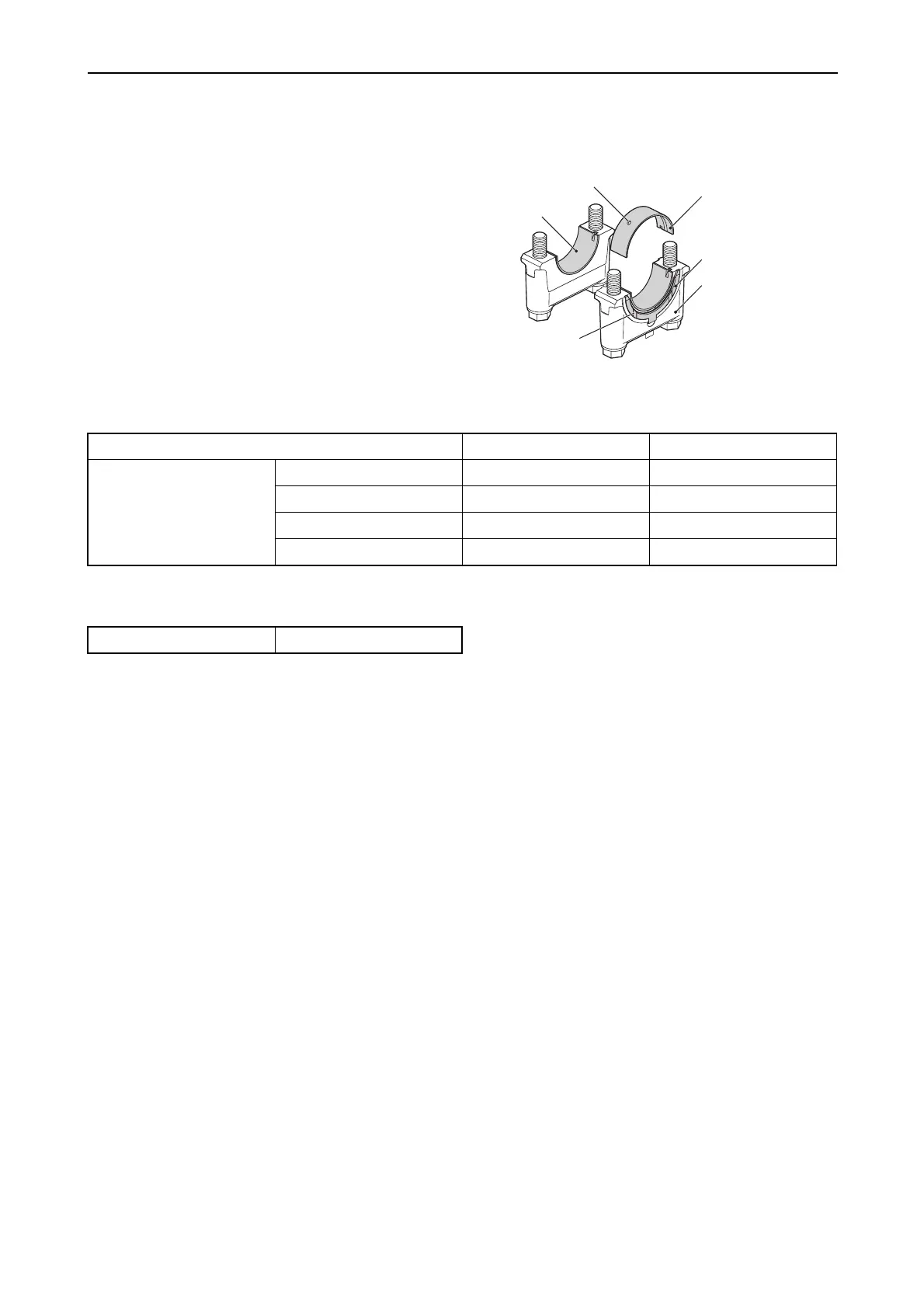

mm

Inspection item Standard Limit

Crank journal

(Selective pairing)

Journal outside diameter 49.952-49.962 49.902

Metal inside diameter 51.000-51.010 -

Metal thickness 1.995-2.010 -

Clearance 0.038-0.068 0.150

Nm (kgf•m)

Tightening torque 96-100 (9.8-10.2)

Groove

Thrust metal

Main bearing cap

(Base)

Lower main

bearing metal

Upper main

bearing metal

Oil hole

Groove

011493-00E

Loading...

Loading...