5. Inspection and servicing of basic engine parts

178

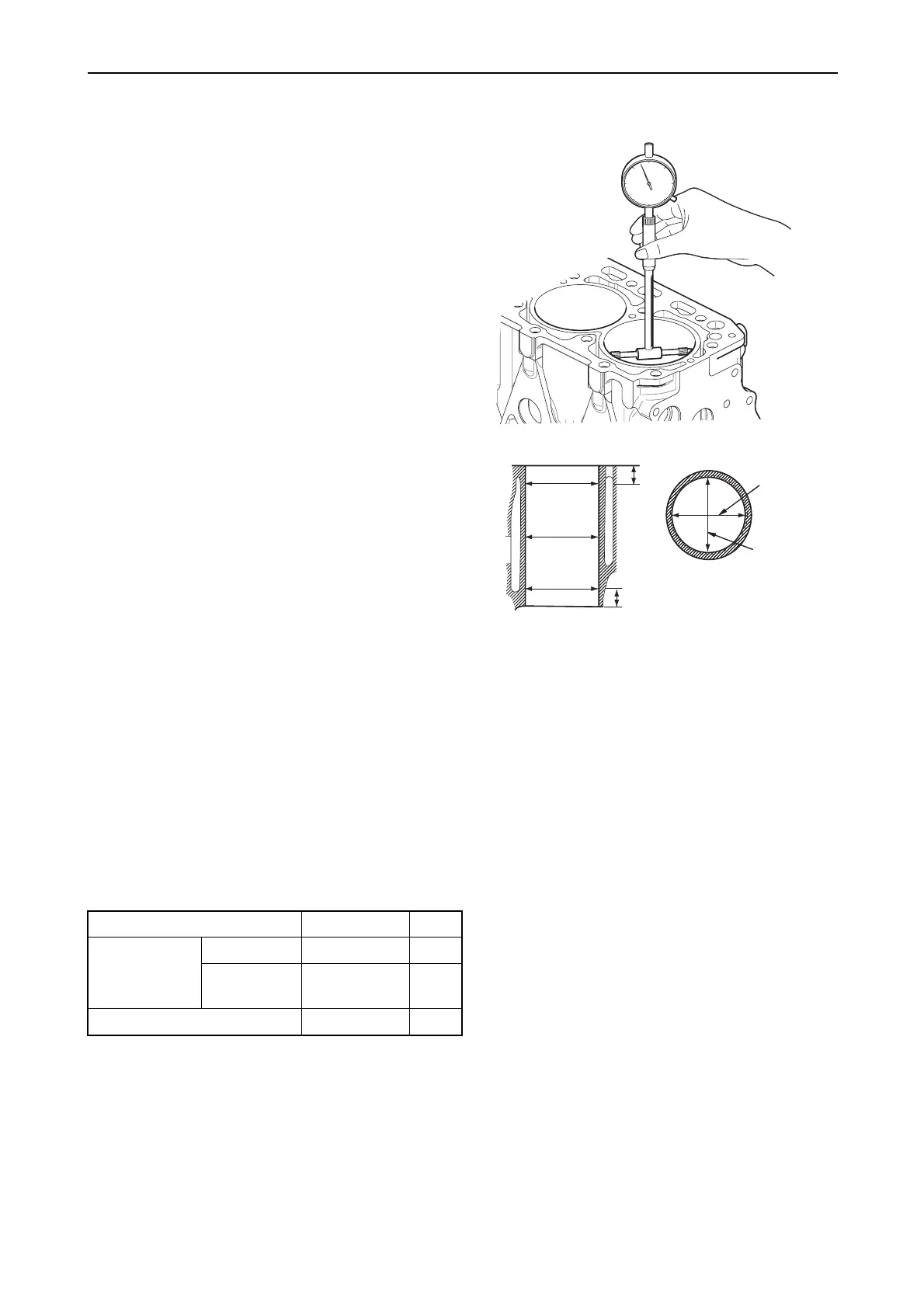

5.1.5 Cylinder bore measurement

Especially clean head surface, cylinder bores and

oil holes, and check the below items after

removing any carbon deposit and bonding agent.

(a) Appearance inspection

Check if there is any discoloration or crack. If

crack is suspected, perform color check.

Sufficiently clean the oil holes and check they

are not clogged.

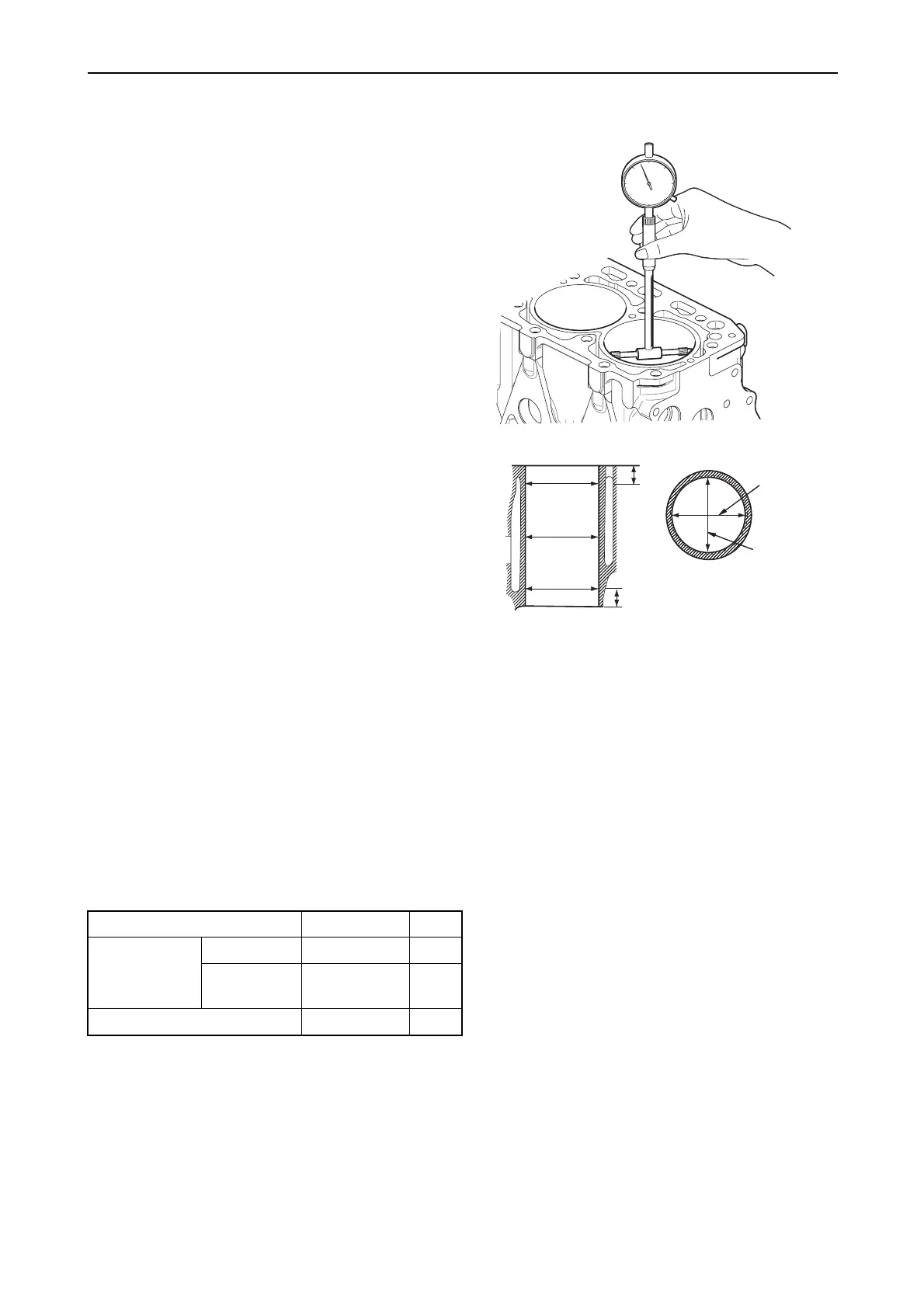

(b) Cylinder bore and distortion

Measure at 20 mm below the crest of the liner,

at 20 mm from the bottom end and at the

center in two directions A and B as shown in

the below figure.

Roundness:

Roundness is found as follows though it is the

simple method. Measure cylinder diameters

of the A direction and the B direction on each

section of a, b and c.

Roundness is the maximum value among

those difference values.

Cylindricity:

Cylindricity is found as follows though it is the

simple method.

Measure cylinder diameters of a, b and c

sections in the A direction, and calculate the

difference in maximum value and minimum

value of the measured diameters.

In the same way measure and calculate the

difference in the B direction.

Cylindricity is the maximum value between

those difference values.

mm

Item Standard Limit

Cylinder bore

diameter

3/4JH4E 88.000~88.030 88.200

4JH4-TE

4JH4-HTE

84.000~84.030 84.200

Cylinder roundness/ Inclination 0.01 or less 0.03

010387-00X

20 mm

A

B

Measure in two directions

A and B at points a, b and c.

a

b

c

20 mm

001495-01E

Loading...

Loading...