5. Inspection and servicing of basic engine parts

210

(3) Camshaft and bearing hole measurement

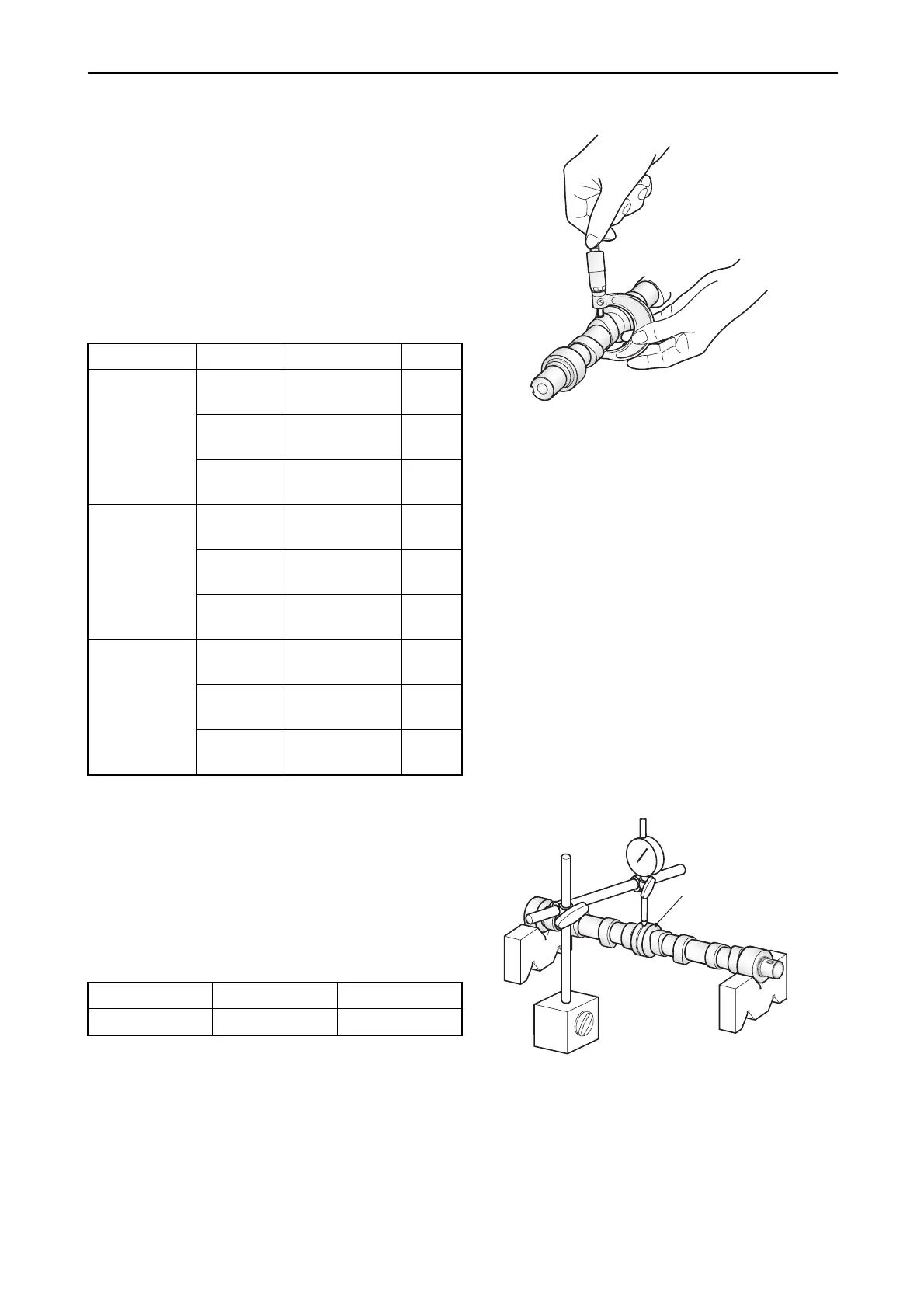

Measure the camshaft outside diameter with a

micrometer. The oil clearance shall be

calculated by subtracting the measured

camshaft outside diameter from the inside

diameter of the camshaft bearing or bushing.

The camshaft bushing at gear case side is

measured with a cylinder gage after insertion

to the cylinder.

Replace if they exceed the limit or are

damaged.

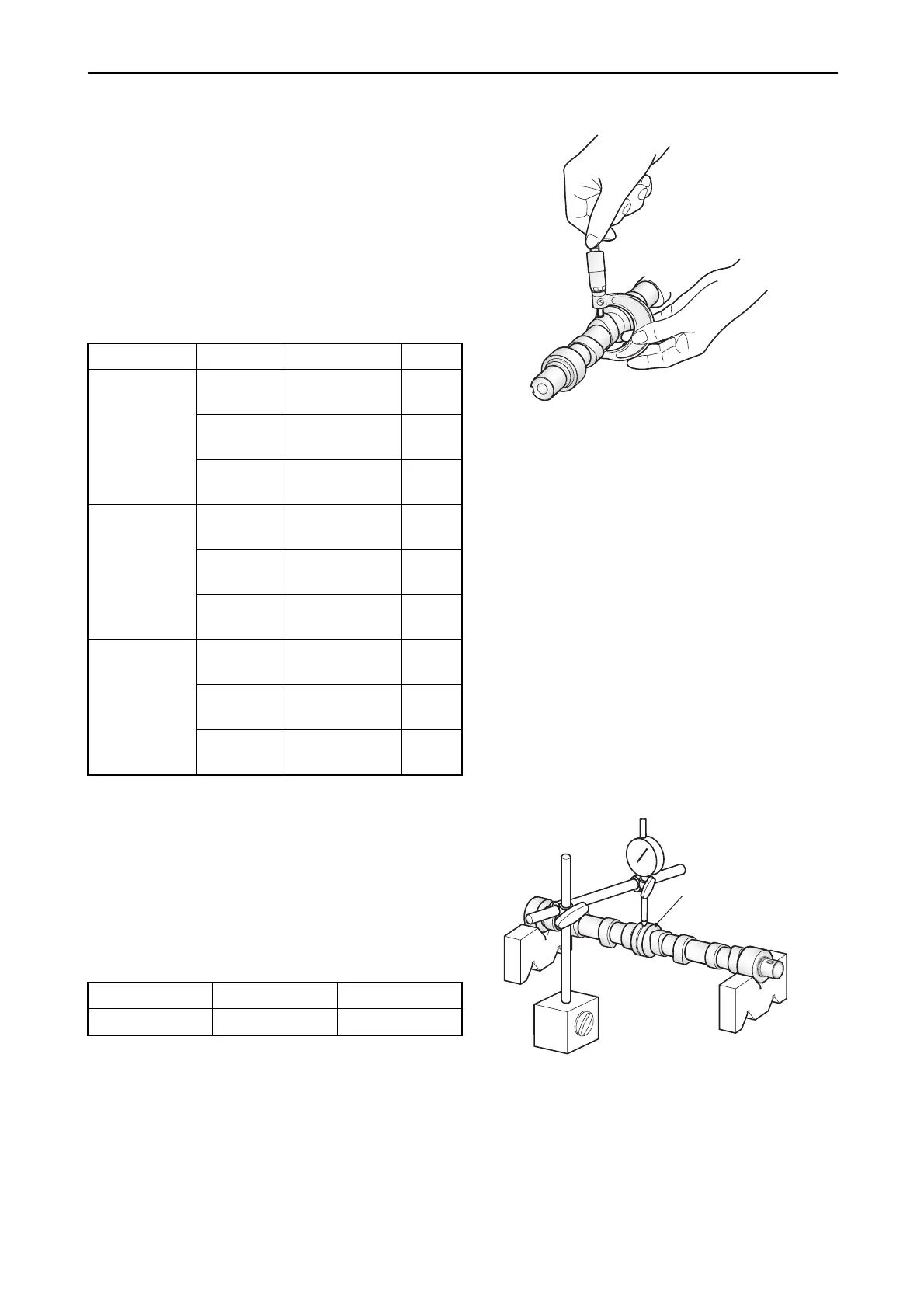

(4) Bending of the camshaft

Support both ends of the camshaft with V-

blocks, place a dial gauge at the central

bearing areas and measure bending. Replace

if excessive.

Note:

The reading on the dial gauge is divided by

two to obtain the camshaft bend.

mm

Place Item Standard Limit

Gear side

(with metal)

Bushing

I.D.

44.990-45.055 45.130

Camshaft

O.D.

44.925-44.950 44.890

Oil

clearance

0.040-0.130 0.240

Intermediate

position

(metal less)

Shaft hole

I.D.

45.000-45.025 45.100

Camshaft

O.D.

44.910-44.935 44.875

Oil

clearance

0.065-0.115 0.225

Flywheel

side

(metal less)

Shaft hole

I.D.

45.000-45.025 45.100

Camshaft

O.D.

44.925-44.950 44.890

Oil

clearance

0.050-0.100 0.210

mm

Standard Limit

Camshaft bend 0.02 or less 0.05

007709-00X

Camshaft

central bearing area

006567-01E

Loading...

Loading...