6. Fuel Injection equipment

229

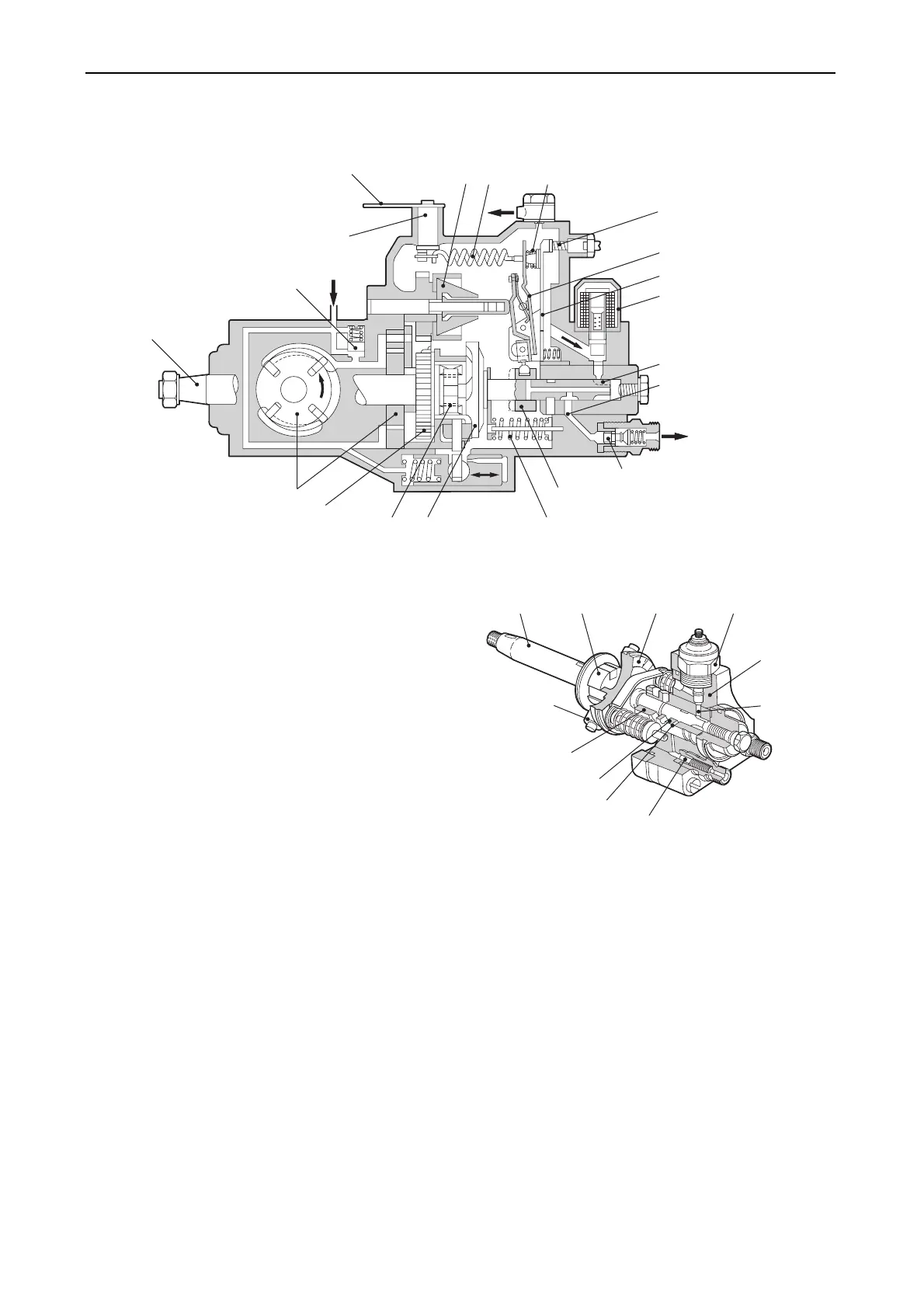

(2) Structure and function

1) Plunger

a) The drive shaft directly receives the engine

rotation by means of gears and transfers

the rotation to the cam disc through the

cross coupling. The positioning pin press-

fitted to the cam disc is also inserted in the

groove of the plunger flange, so that the

plunger and cam disc rotate in the same

direction.

The cam disc has a face cam to reciprocate

by a specified cam lift on the roller of the

roller holder assembly.

b) There are two plunger springs having

setting forces on the outside of the plunger.

The return the plunger which is pushed up

by the cam disc, in the descending

process. That is, the plunger rotates by

means of the drive shaft and reciprocates

by means of the cam disc.

When the fuel whose pressure is increased

by the plunger is sent to the outlet port, the

delivery valve opens to allow the fuel to be

injected into the combustion chamber

through the fuel injection nozzle.

Governor

springFlyweight

Control lever

Control lever shaft

Regulating valve

Drive shaft

Feed pump

Drive gear

Cross coupling

Cam disc

Plunger spring

Control sleeve

Delivery valve

Outlet port

Plunger

Magnetic valve

Governor lever assembly

Tension lever

Full load

adjusting screw

Idling spring

010346-00E

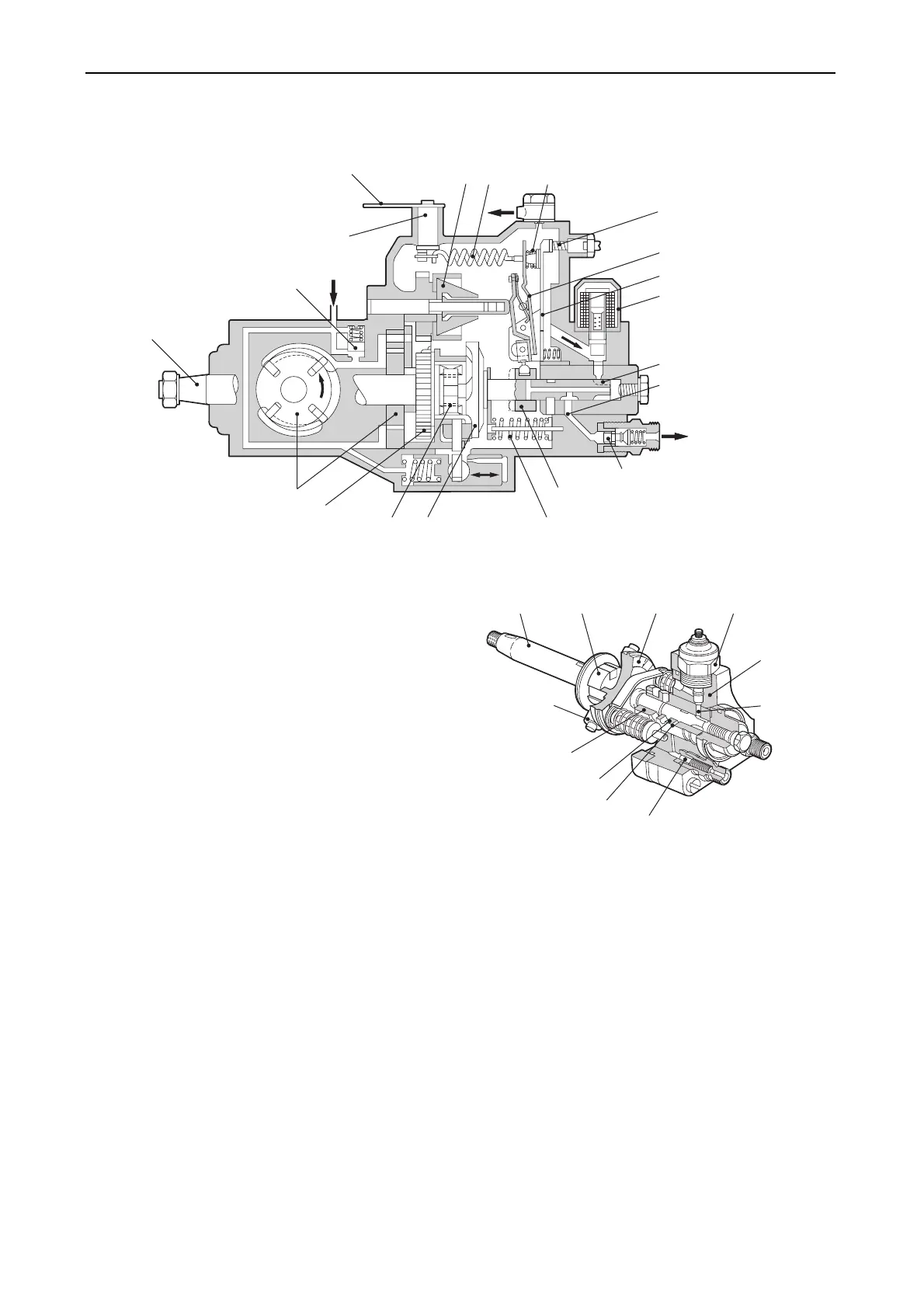

Drive shaft Cross coupling Cam disc Magnetic valve

Distributo

head

Delivery valve

Outlet port

Plunger barrel

Control

sleeve

Roller

Inlet port

010347-00E

Loading...

Loading...