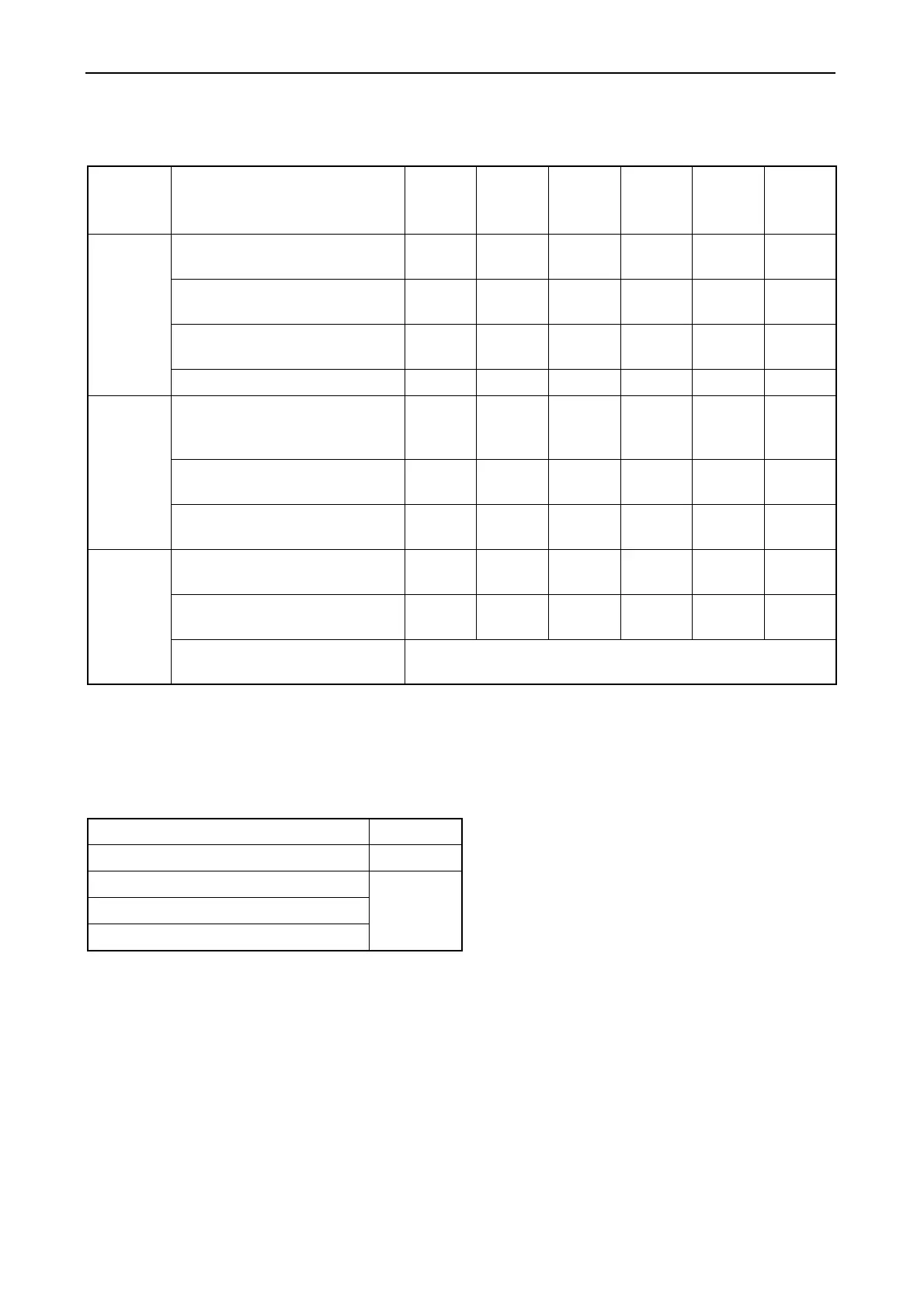

2. Inspection and adjustment

53

*1

For EPA requirements see also 1.6 in chapter 1.

*2

Whichever comes first.

Inspection and maintenance for the EPA emission

related parts.

{ : User-maintenance Å : Parts replacement z : Shop-inspection

System Item

Before

starting

*2

Initial

50hrs. or

one month

*2

Every

50hrs. or

one month

*2

Every

250 hrs. or

one year

*2

Every

500 hrs. or

2 years

*2

Every

1000 hrs. or

4 years

Electrical

system

Check the alarm lamps and

devices

{

Check the electrolyte level in the

battery

{

Adjust the tension of the

alternator driving belt

{{

Å

Check the wiring connectors {

Cylinder

head,

etc.

Check the leakage of water,

lube oil and fuel.

{

(After

starting)

Retighten all major nuts and

bolts

z

Adjust intake/exhaust valve

clearance

z z

Remote

control

system,

etc.

Check/adjust the remote control

operation

{{ z

Adjust the propeller shaft

alignment

zz

Replace rubberized hoses (for

water and fuel)

Every two years or 2,000hrs of operation *

2

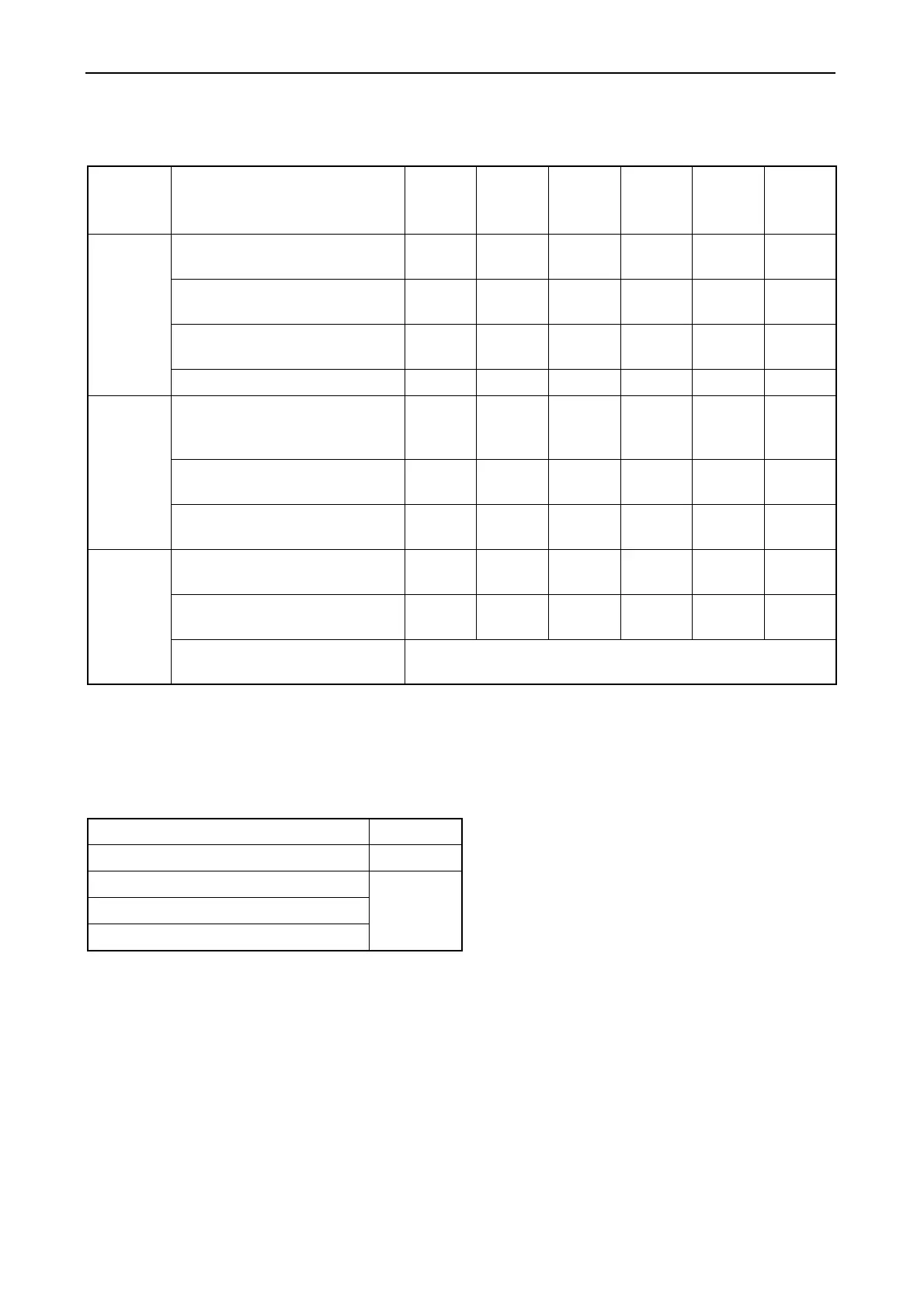

Parts Interval

Check fuel injection nozzle (cleaning) 1,500 hours

Check fuel injection nozzle (adjustment)

3,000 hoursCheck fuel injection pump (adjustment)

Check turbocharger (adjustment)

Loading...

Loading...