1.2 b: Application

YASKAWA ELECTRIC SIEP C710606 10A YASKAWA AC Drive - V1000 PRELIM. Programming Manual 61

Parameter Details

1

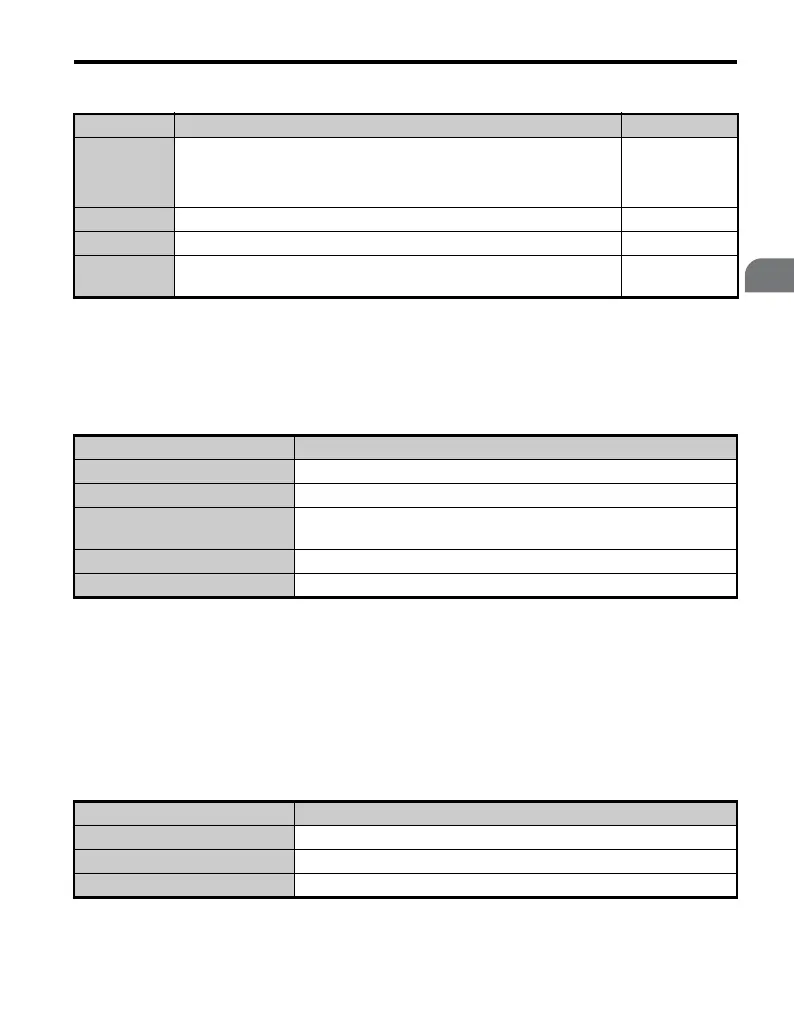

■ PID Setpoint Input Methods

When the PID control parameter b5-01 is set to 1 or 2, the frequency reference in b1-01 (or

b1-15) becomes the PID setpoint. If b5-01 is set to 3 or 4, then the PID setpoint can be input

from one of the sources in the following table.

Table 1.21 PID Setpoint Sources

Note: A duplicate allocation of the PID setpoint input will result in an OPE alarm.

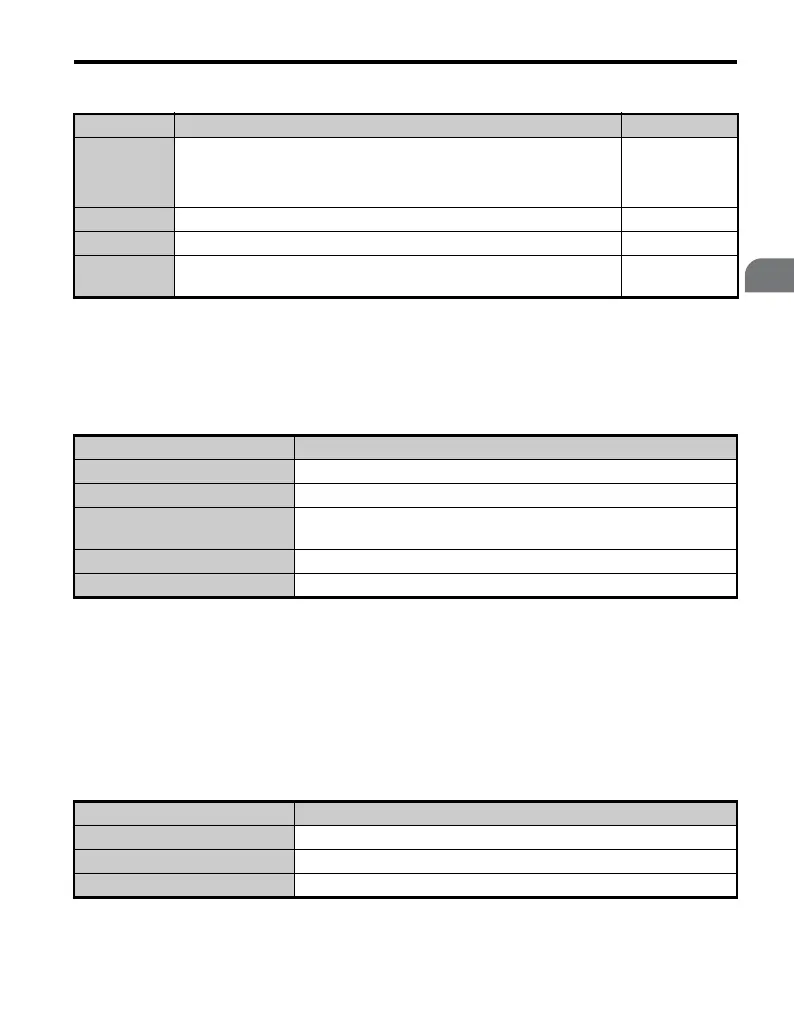

■ PID Feedback Input Methods

Either one feedback signal can be input for normal PID control or two feedback signals can

be input for controlling a differential process value.

Normal PID Feedback

The PID feedback can be input from one of the sources listed below.

Table 1.22 PID Feedback Sources

Application Description Sensors Used

Speed Control

Machinery speed is fed back and adjusted to meet the target value.

Synchronous control is performed using speed data from other

machinery as the target value

Tachometer

Pressure Maintains constant pressure using pressure feedback. Pressure sensor

Fluid Control Keeps flow at a constant level by feeding back flow data. Flow rate sensor

Temperature

Control

Maintains a constant temperature by controlling a fan with a

thermostat.

Thermocoupler,

Thermistor

PID Setpoint Source Settings

Analog Input A1 Set H3-02 = C

Analog Input A2 Set H3-10 = C

MEMOBUS/Modbus

Register 0006H

Set Bit 1 in register 000FH to 1 and input the setpoint to register

0006H

Pulse Input RP Set H6-01 = 2

Parameter b5-19 Set parameter B5-18 = 1 and input the PID setpoint to b5-19

PID Feedback Source Settings

Analog Input A1 Set H3-02 = B

Analog Input A2 Set H3-10 = B

Pulse Input RP Set H6-01 = 1

Loading...

Loading...