n

Wire Size and Torque Specifications

Select appropriate wire type and size from Table 3.9. For simpler and more reliable wiring,

crimp ferrules to the wire ends. Refer to Table 3.10 for ferrule terminal types and sizes.

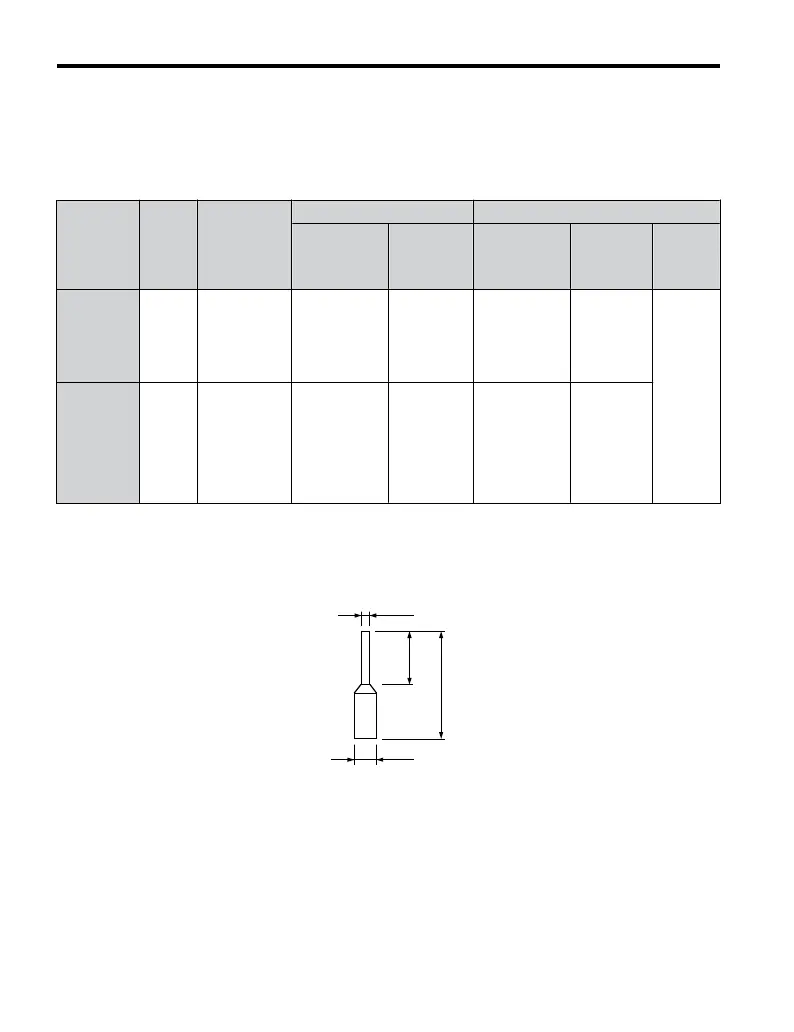

Table 3.9 Wire Size and Torque Specifications (Same for All Models)

Terminal

Screw

Size

Tightening

Torque

N•m

(in-lbs)

Bare Wire Terminal Ferrule-Type Terminal

Applic. wire

size

mm

2

(AWG)

Recomm.

mm

2

(AWG)

Applic. wire

size

mm

2

(AWG)

Recomm.

mm

2

(AWG)

Wire

Type

MA, MB,

MC

M3

0.5 to 0.6

(4.4 to 5.3)

Stranded: 0.25

to 1.5

(24 to 16)

Single: 0.25 to

1.5

(24 to 16)

0.75 (18)

0.25 to 1.0

(24 to 17)

0.5 (20)

Shielded

line, etc.

S1-S7, SC,

RP, +V, A1,

A2, AC, HC,

H1, P1, P2,

PC, MP,

AM, AC, S

+, S-, R+, R-,

IG

M2

0.22 to 0.25

(1.9 to 2.2)

Stranded: 0.25

to 1.0

(24 to 18)

Single: 0.25 to

1.5

(24 to 16)

0.75 (18)

0.25 to 0.5

(24 to 20)

0.5 (20)

n

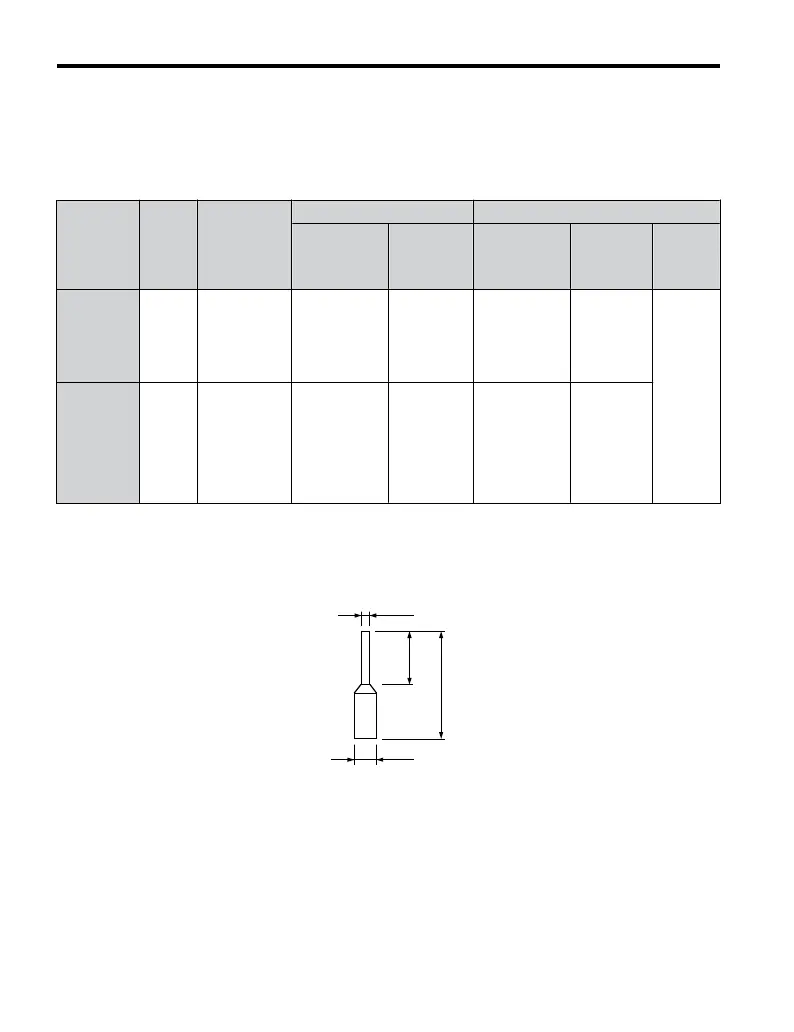

Ferrule-Type Wire Terminations

Crimp a ferrule to signal wiring to improve wiring simplicity and reliability. Use CRIMPFOX

ZA-3, a crimping tool manufactured by PHOENIX CONTACT.

d1

d2

6 mm

L

Figure 3.16 Ferrule Dimensions

3.5 Control Circuit Wiring

70

YASKAWA ELECTRIC TOEP C710606 47A YASKAWA AC Drive – V1000 Quick Start Guide

Loading...

Loading...