Parameters 347

DIO1 Digital input/output DIO1 (11.02 DIO delayed status, bit 0). 10

DIO2 Digital input/output DIO2 (11.02 DIO delayed status, bit 1). 11

Other [bit] Source selection (see Terms and abbreviations on page 148). -

40.31 Set 1 deviation

inversion

Inverts the input of the process PID controller.

0 = Deviation not inverted (Deviation = Setpoint - Feedback)

1 = Deviation inverted (Deviation = Feedback - Setpoint)

See also section Sleep function for process PID control (page

104).

Not inverted

(Ref - Fbk)

Not inverted

(Ref - Fbk)

0. 0

Inverted (Fbk - Ref) 1. 1

Other [bit] Source selection (see Terms and abbreviations on page 148). -

40.32 Set 1 gain Defines the gain for the process PID controller. See

parameter 40.33 Set 1 integration time.

1.00

0.10 … 100.00 Gain for PID controller. 100 = 1

40.33 Set 1 integration

time

Defines the integration time for the process PID controller.

This time needs to be set to the same order of magnitude as

the reaction time of the process being controlled, otherwise

instability will result.

Note: Setting this value to 0 disables the “I” part, turning the

PID controller into a PD controller.

60.0 s

0.0 … 32767.0 s Integration time. 1 = 1 s

40.34 Set 1 derivation

time

Defines the derivation time of the process PID controller. The

derivative component at the controller output is calculated on

basis of two consecutive error values (E

K-1

and E

K

) according

to the following formula:

PID DERIV TIME × (E

K

- E

K-1

)/T

S

, in which

T

S

= 2 ms sample time

E = Error = Process reference - process feedback.

0.000 s

0.000 … 10.000 s Derivation time. 1000 = 1 s

No. Name/Value Description Def/FbEq16

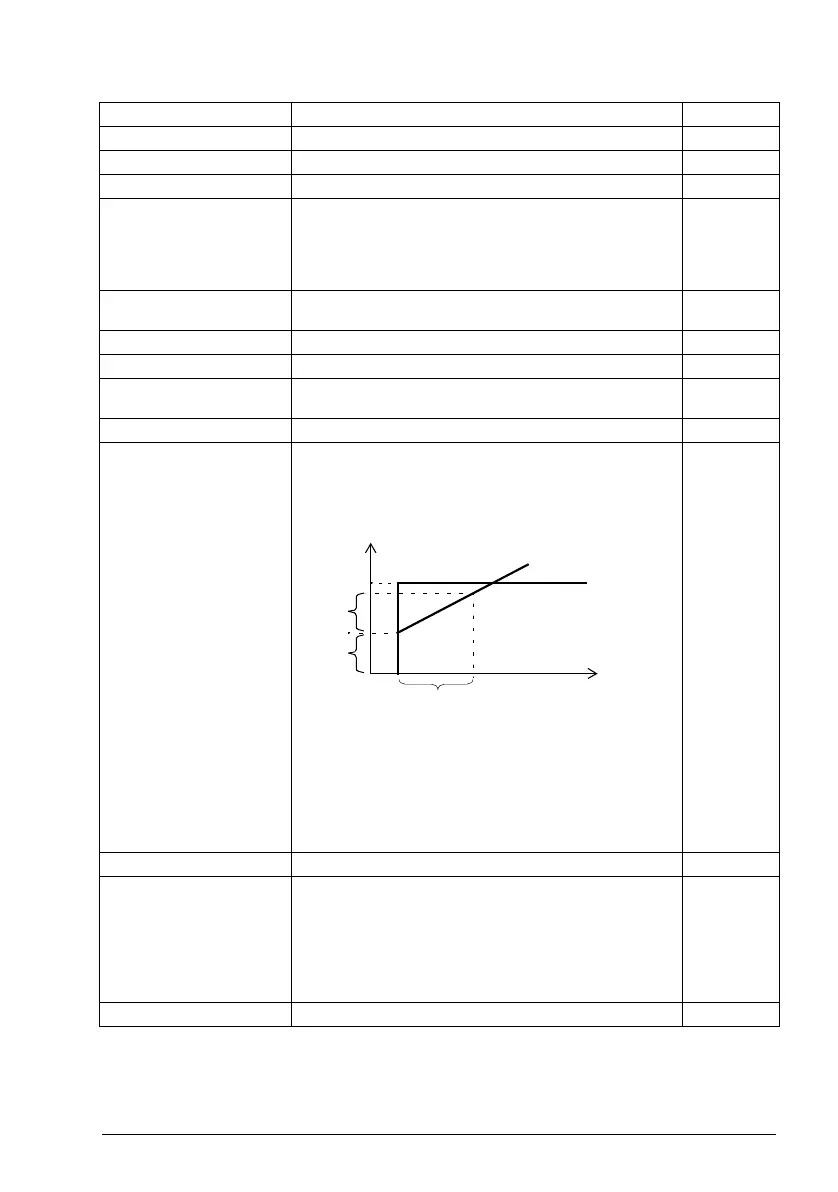

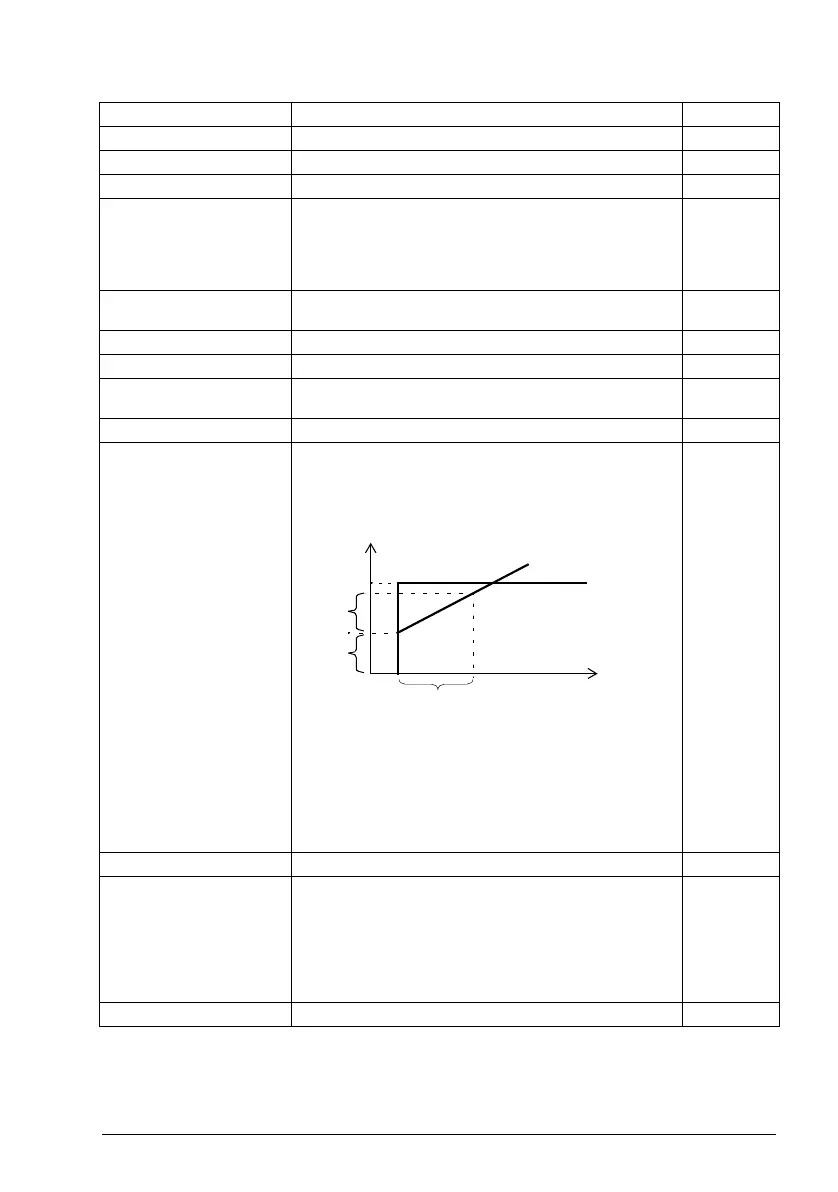

Ti

O

I

G × I

G × I

I = controller input (error)

O = controller output

G = gain

Ti = integration time

Time

Error/Controller output

Loading...

Loading...