140 Application macros

Torque control macro

This macro is used in applications in which torque control of the motor is required.

These are typically tension applications, where a particular tension needs to be

maintained in the mechanical system.

Torque reference is given through analog input AI2, typically as a current signal in the

range of 0…20 mA (corresponding to 0…100% of rated motor torque).

The start/stop signal is connected to digital input DI1. The direction is determined by

DI2. Through digital input DI3, it is possible to select speed control (EXT1) instead of

torque control (EXT2). As with the PID control macro, speed control can be used for

commissioning the system and checking the motor direction.

It is also possible to change the control to local (control panel or PC tool) by pressing

the Loc/Rem key. By default, the local reference is speed; if a torque reference is

required, the value of parameter 19.16 Local control mode should be changed to

Torque.

A constant speed (by default, 300 rpm) can be activated through DI4. DI5 switches

between acceleration/deceleration time sets 1 and 2. The acceleration and

deceleration times, as well as ramp shapes, are defined by parameters

23.12…23.19.

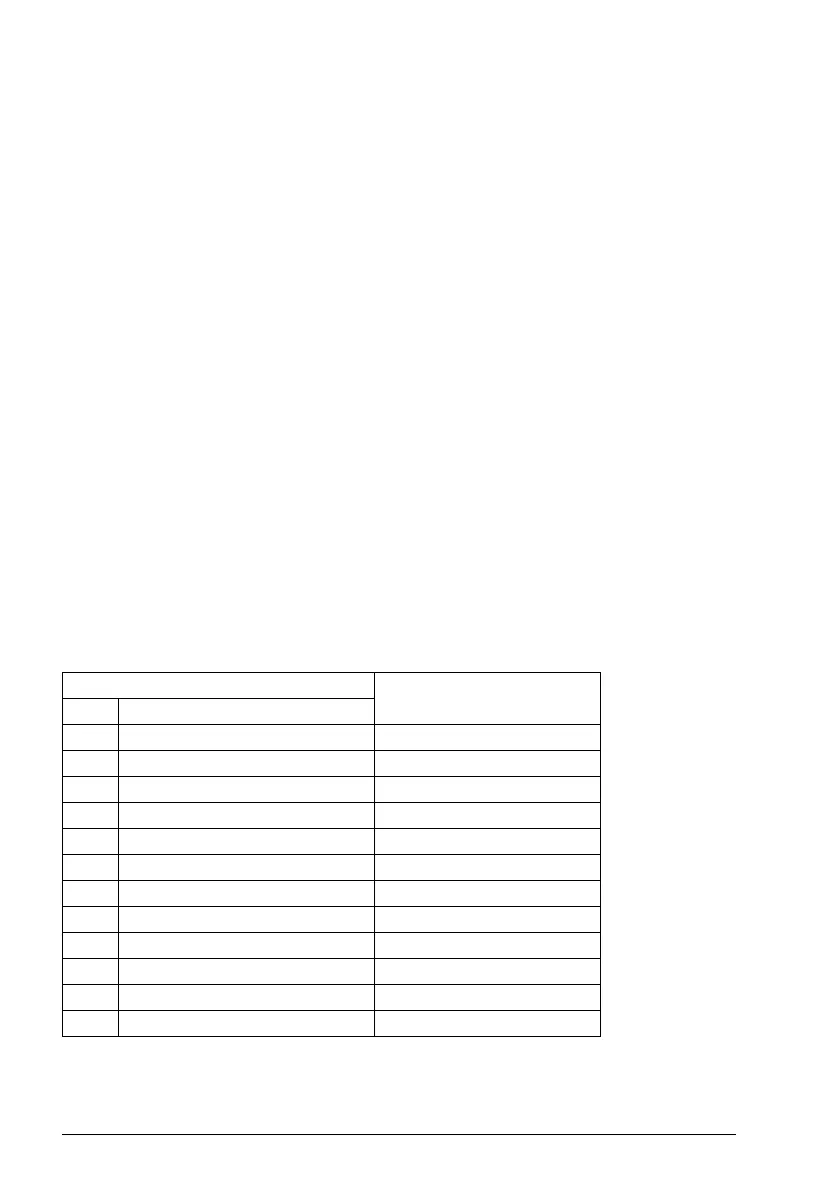

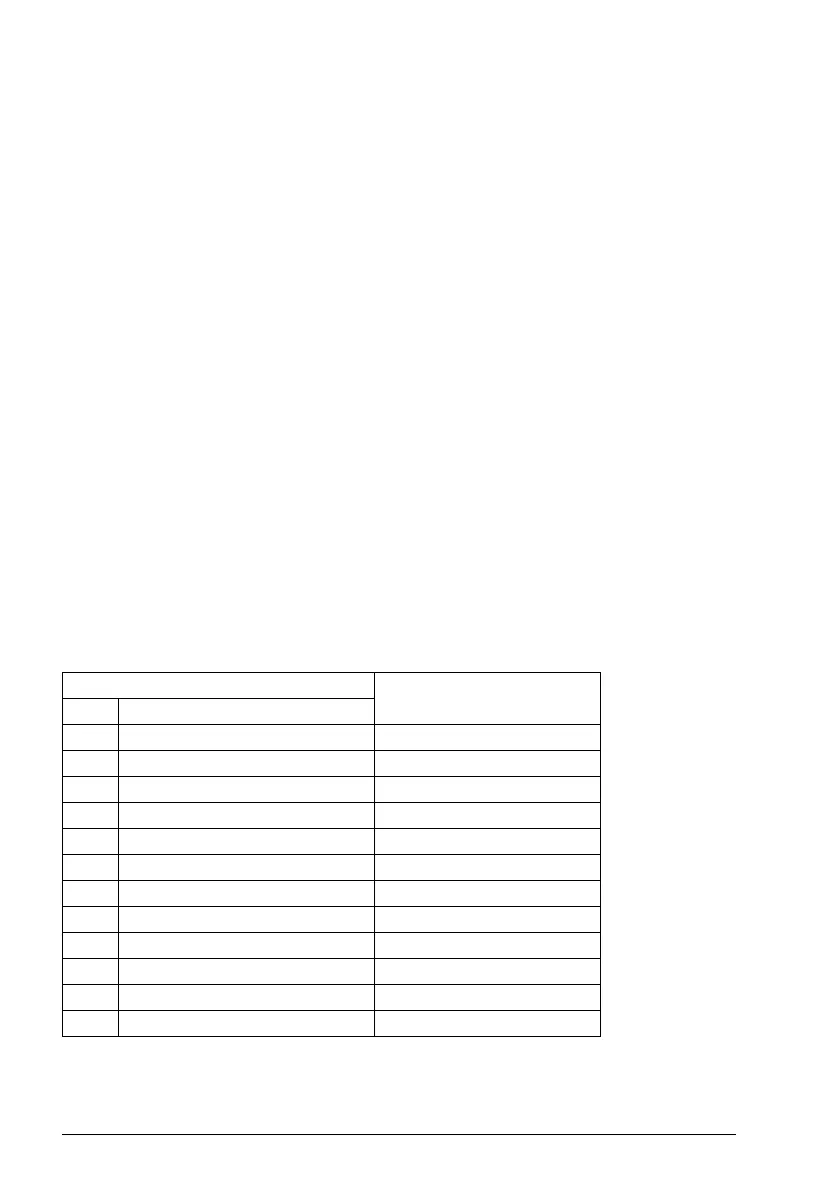

Default parameter settings for the Torque control macro

Below is a listing of default parameter values that differ from those listed for the

Factory macro in Parameter listing (page 152).

Parameter

Torque control macro

default

No. Name

19.11 Ext1/Ext2 selection DI3

19.14 Ext2 control mode Torque

20.02 Ext1 start trigger type Level

20.06 Ext2 commands In1 Start; In2 Dir

20.07 Ext2 start trigger type Level

20.08 Ext2 in1 source DI1

20.09 Ext2 in2 source DI2

20.12 Run enable 1 source DI6

22.22 Constant speed sel1 DI4

23.11 Ramp set selection DI5

26.11 Torque ref1 source AI2 scaled

31.11 Fault reset selection Not selected

Loading...

Loading...