325P350 Rev1

(4D35/3255/MK05 Service Manual)

Page 3 of 4

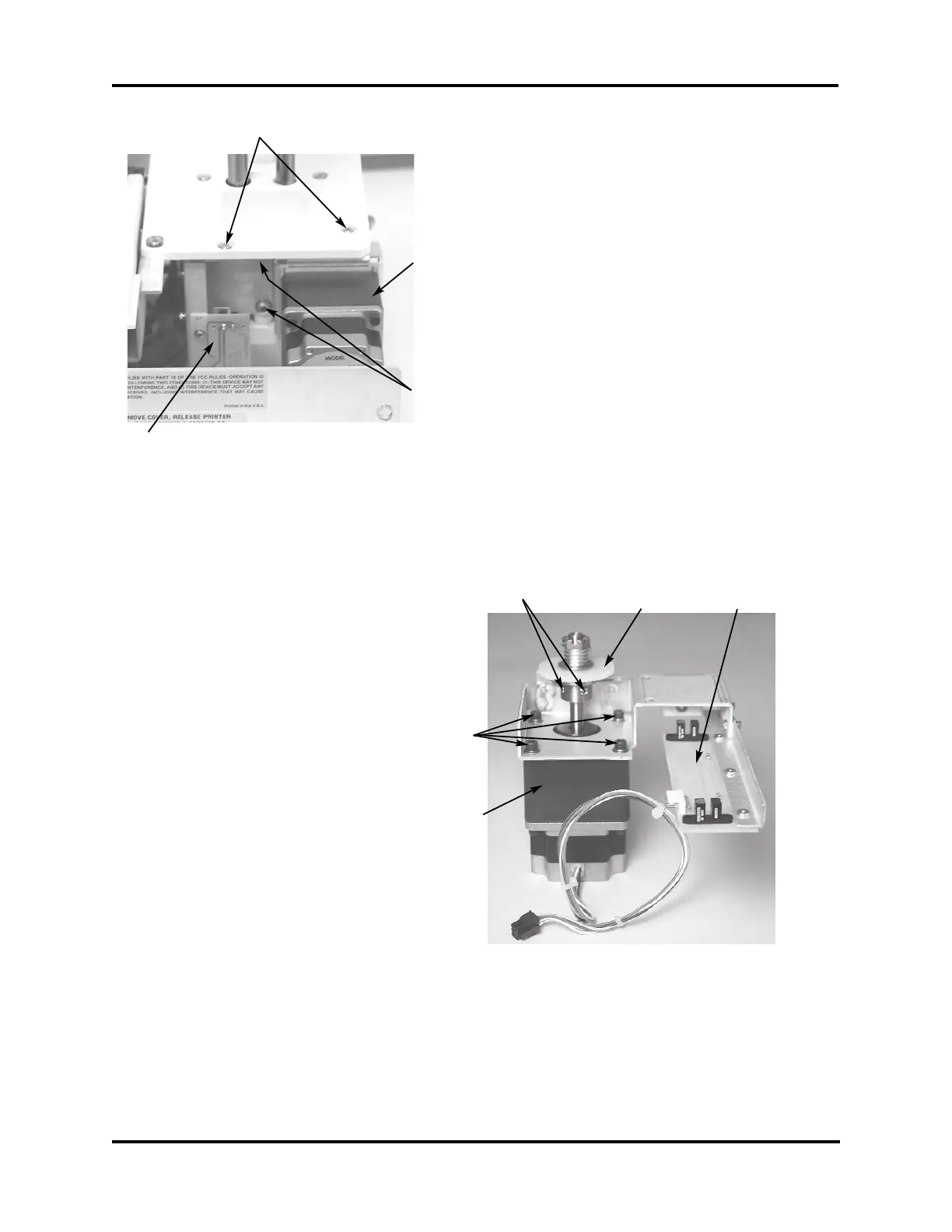

5. Disconnect the harness connected to the

bottom of the Head Up/Down PCB (not

shown).

6. Remove the motor assembly mounting

screws (H) below the deck. A short or

right-angle screwdriver may help to

access these screws.

7. Remove the motor assembly mounting

screws (I) through the top surface of the

deck, then lift the motor assembly out of

the instrument and place on a flat, clean

surface near the instrument.

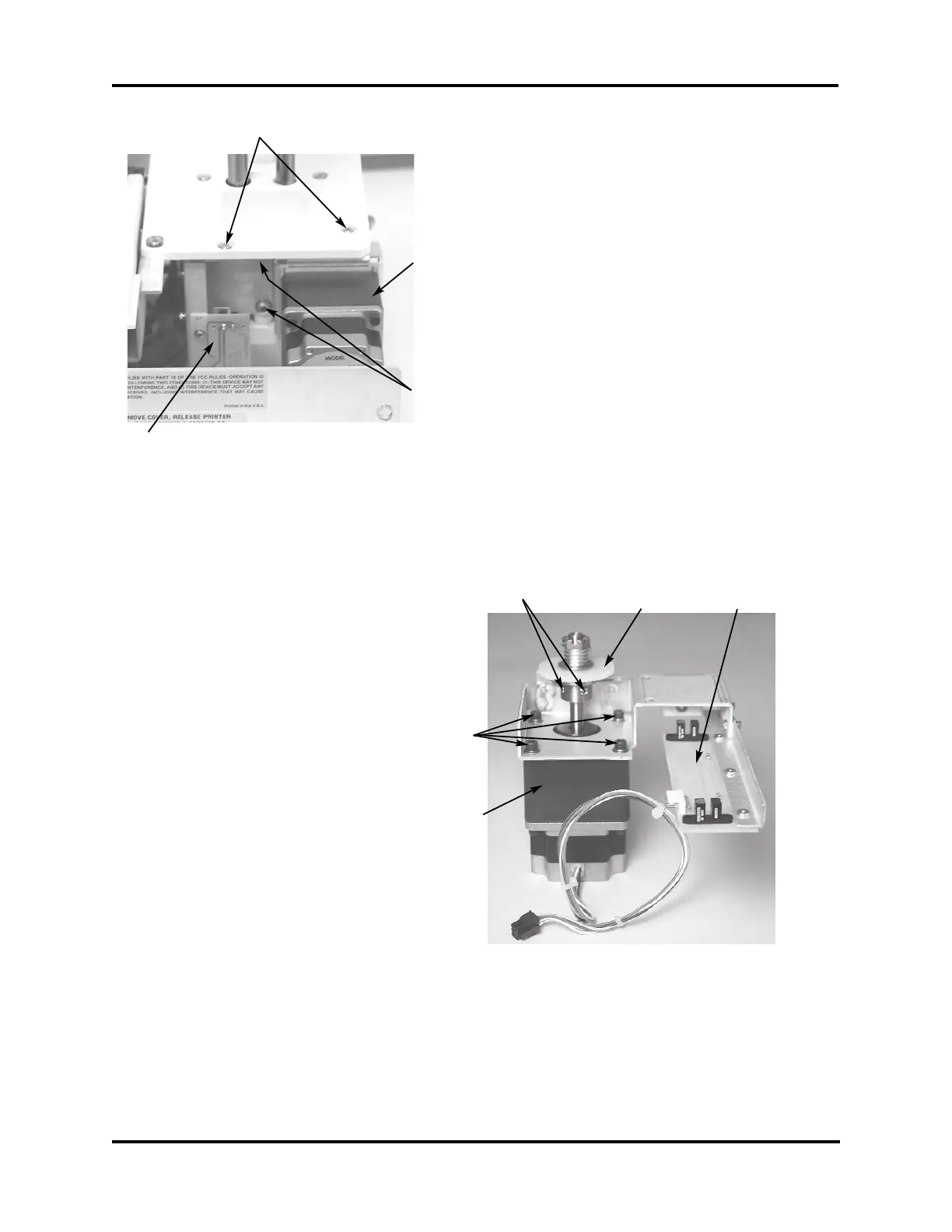

8. Measure the space between the plastic

gear on the clutch assembly to the surface

of the motor mounting bracket so that it

can be replaced in the same location on

the replacement motor. Using the 1/16”

Allen wrench, remove the two Allen

setscrews (J) that secure the clutch

assembly to the motor shaft, then remove

the clutch assembly. If necessary, use a

screwdriver to gently pry the clutch

assembly from the shaft.

9. Using the 9/64” Allen wrench, remove

the four screws (K) that secure the motor

to the bracket, and remove the motor.

10. Assemble the replacement motor to the

motor mounting bracket using the four

screws (K).

11. Slide the clutch assembly onto the

replacement motor shaft and tighten the

two Allen setscrews, making sure to

locate the clutch assembly per the meas-

urement taken in Step 8.

12. Install the motor assembly into the instru-

ment using the two screws (I) through the

surface of the deck. Make sure the teeth

of the plastic gear are properly meshed

with the gear rack on the sample head

shaft, and the motor mounting bracket is

pressed firmly against the lower back sur-

face of the deck casting. Tighten the two

screws.

Figure 4

Figure 5

I

Motor

H

Head Up/

Down PCB

Clutch

Assembly

J

Head Up/

Down PCB

Motor

K

Loading...

Loading...