ELECTRICAL

Battery Cleaning

Keep the battery terminals and connections free of corrosion.

If cleaning is necessary, remove the corrosion with a stiff wire

brush. Wash with a solution of one tablespoon baking soda and

one cup water. Rinse well with tap water and dry off with

clean shop towels. Coat the terminals with dielectric grease or

petroleum jelly.

Battery Installation

1. Place the fully charged battery in its holder.

2. Attach the hold-down strap(s).

3. Connect and tighten the red positive (+) cable first.

4. Connect and tighten the black negative (-) cable last.

5. Torque the battery terminal bolts to 3.5 ft. lbs. (4.7 Nm)

6. Verify that the cables are properly routed.

NOTE: When installing a new battery, make sure it's

fully charged prior to its initial use. Using a new

battery that has not been fully charged can damage

the battery and result in a shorter life. It can also

hinder vehicle performance. If charging is

use a .5 amp battery charger.

Battery Voltage Test

Battery voltage should be checked with a digital multi-tester.

Readings of 12.4 or less require further battery testing and

charging. See Load Test.

NOTE: Batteries should be kept at or near a full

charge as possible. If the battery is stored or used in

a partially charged condition, crystal sulfation will

form on the plates, reducing the efficiency and

service life of the battery.

Battery Load Test

CAUTION

Remove the spark plug high tension lead and connect

securely to engine ground before proceeding.

A battery may indicate a full charge condition in the battery

voltage test and the specific gravity test, but still may not have

the storage capacity necessary to properly function in the

electrical system.

For this reason, a battery capacity or load test should be

conducted whenever poor battery performance is suspected. To

perform this test:

1. Connect a multi-tester to the battery in the same manner as

was done in the battery voltage test. The reading should be

12.4 volts or greater.

2. Engage the electric starter and view the registered battery

voltage while cranking the engine. Continue the test for 15

seconds. During this cranking period, the observed voltage

should not drop below 9.5 volts.

3. If the beginning voltage is 12.6 or higher and the cranking

voltage drops below 9.5 volts during the test, replace the

battery.

Battery Charging Procedure

Charge the battery using a charger capable of producing

voltage

1/10th of the battery’s amp/hr rating. Example: COBRA 50

ATV batteries have an amp/hr rating of 4.85 amps. Do not

exceed .5 amps charging voltage or damage to the battery will

result.

Fully charged, the battery should read 12.8-13.0 Volts. After

charging is complete, let the battery stand 1-2 hours and re-test

the voltage. Do not overcharge the battery!

There is no need to remove the cell cap strip or add water for

the life of the battery.

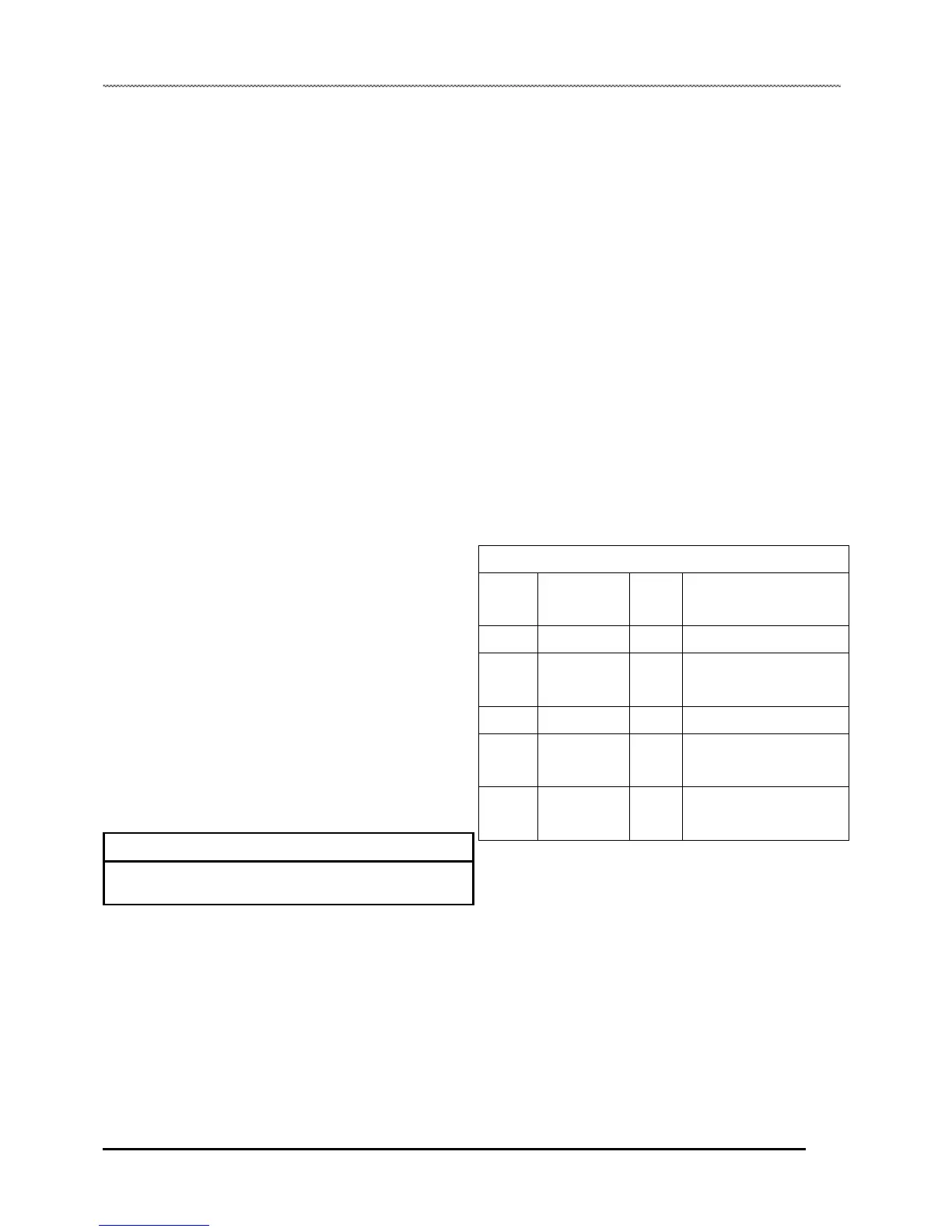

COBRA 50/100 ATV BATTERY CHARGING CHART

State of

Charge

CHARGE TIME

100% 12.8-13.0V None FULL None Required

75%

12.5-12.8V Slight

Charge

3-6 Hours @ 0.5 A

50% 12-12.5V Charge

5-11 Hours @ 0.5 A

25%

11.5-12.0V Charge

13+ Hours @ 0.5 A

Check Charging

0%

Less than

11.5v

Charge

20 Hours @ 0.5 A

Battery may be dead

Because of the characteristics of a sealed battery, overcharging

decreases the volume of electrolyte. The longer the overcharge

time, the greater the drop in electrolyte, and subsequently

starting power. Water cannot be added to a sealed battery. If a

sealed battery is overcharged, it will have to self-discharge

before it can be used. Overcharging can also warp plates,

making future charging difficult. Watch charging times

carefully, or use a charger with limited charging time/current

capabilities. Always stop charging if the battery becomes

warm to the touch. Let it cool sufficiently before resuming

charging.

8.14

Loading...

Loading...