ENGINE / TRANSMISSION

Transmission Inspection

NOTE: Always wear the appropriate protective gear and

use caution when operating a press.

1. With transmission components removed, inspect

all shaft bearings visually and by feel. Bearings

should roll smoothly, without excessive movement

or noise. Replace any bearing that is removed, as the

removal process destroys the bearing.

2. Bearings can be removed using a standard blind bearing

remover. Apply lithium grease to outer race of new bearings

and press into cover or case by the outer race. Do not press on

inner race or bearing will be damaged.

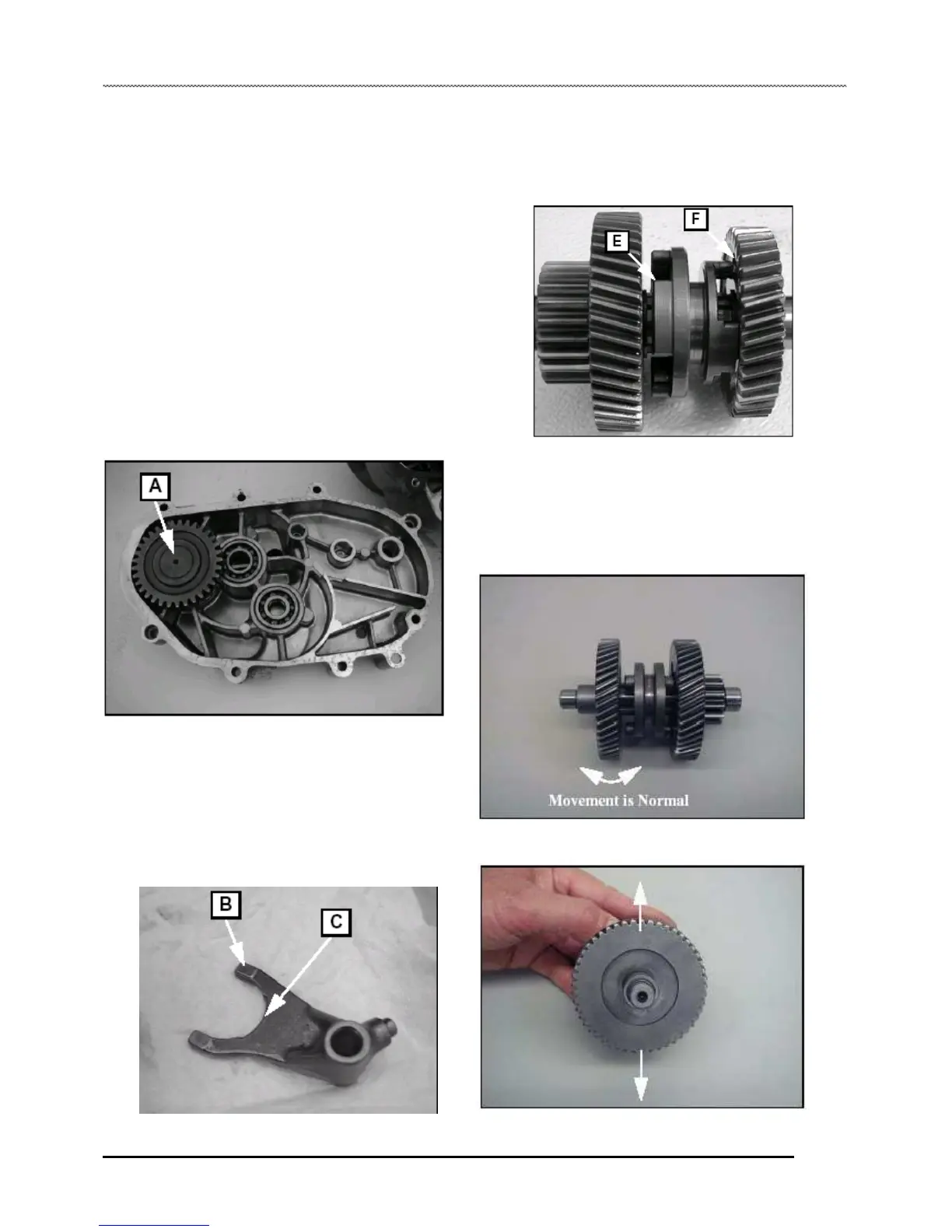

3. Press output shaft (A) out of cover with an arbor press or a

hydraulic press from outside to inside, while supporting cover

completely.

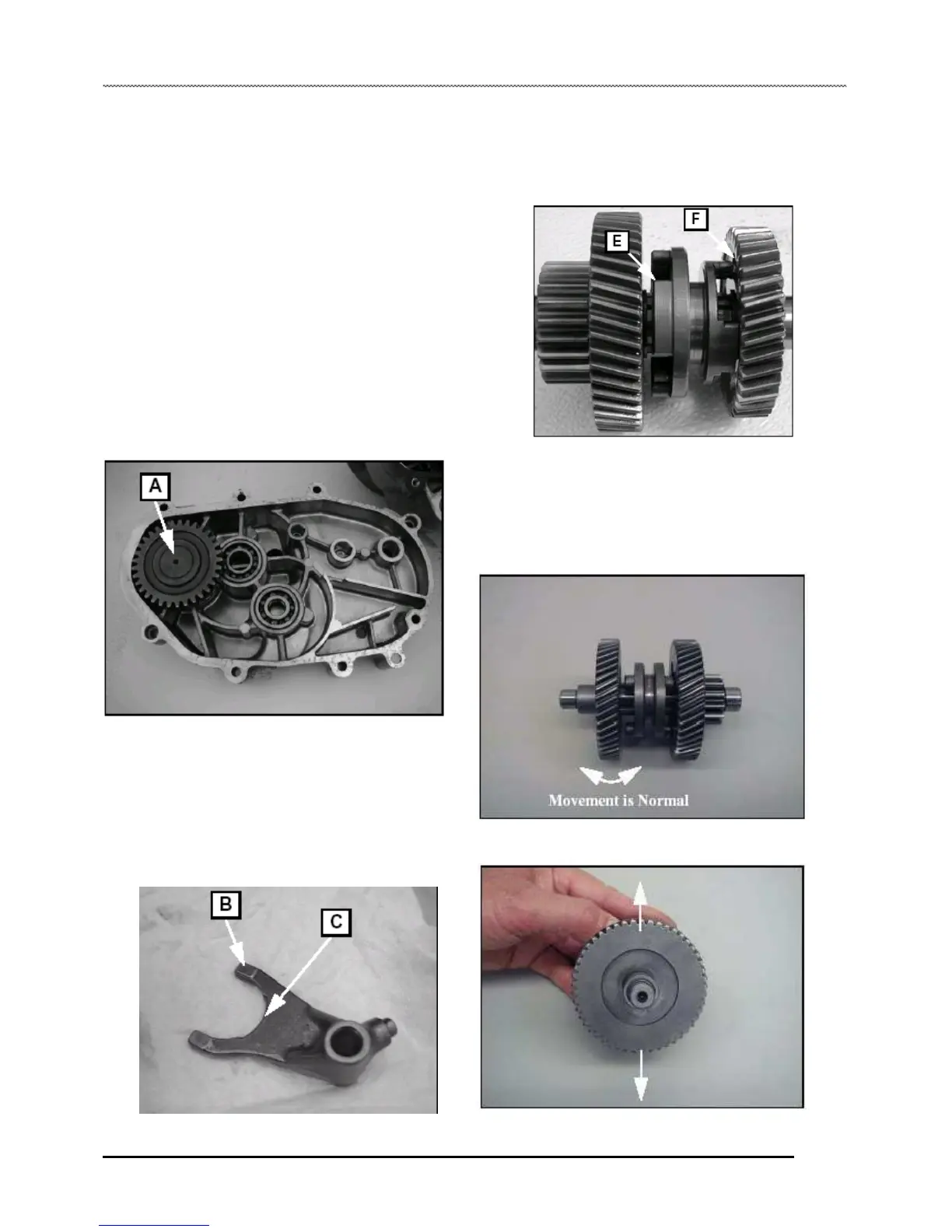

5. Inspect sliding gear dogs and dog slots in the mating gears

(F) for wear or damage. The edges of dogs and slots should

be square and not rounded. Replace both sliding gear and

mating gears if any edges are rounded or chipped.

NOTE: Inspect all shafts for wear in the bearing

contact areas. The sealed output shaft bearing (in

transmission cover) has a snap ring that must be

removed before output shaft bearing can be pressed

out of the cover.

6. Substantial axial movement in the forward drive gear is due

to liberal oil clearance for the bushing, and is a normal

condition. Gear replacement is not required due to axial

movement if radial movement (shown in Step 6) passes

inspection.

4. Inspect the shift fork ( B ) for scoring or signs of wear. Area

Loading...

Loading...