FUEL SYSTEM

Air / Fuel Mixture Ratio

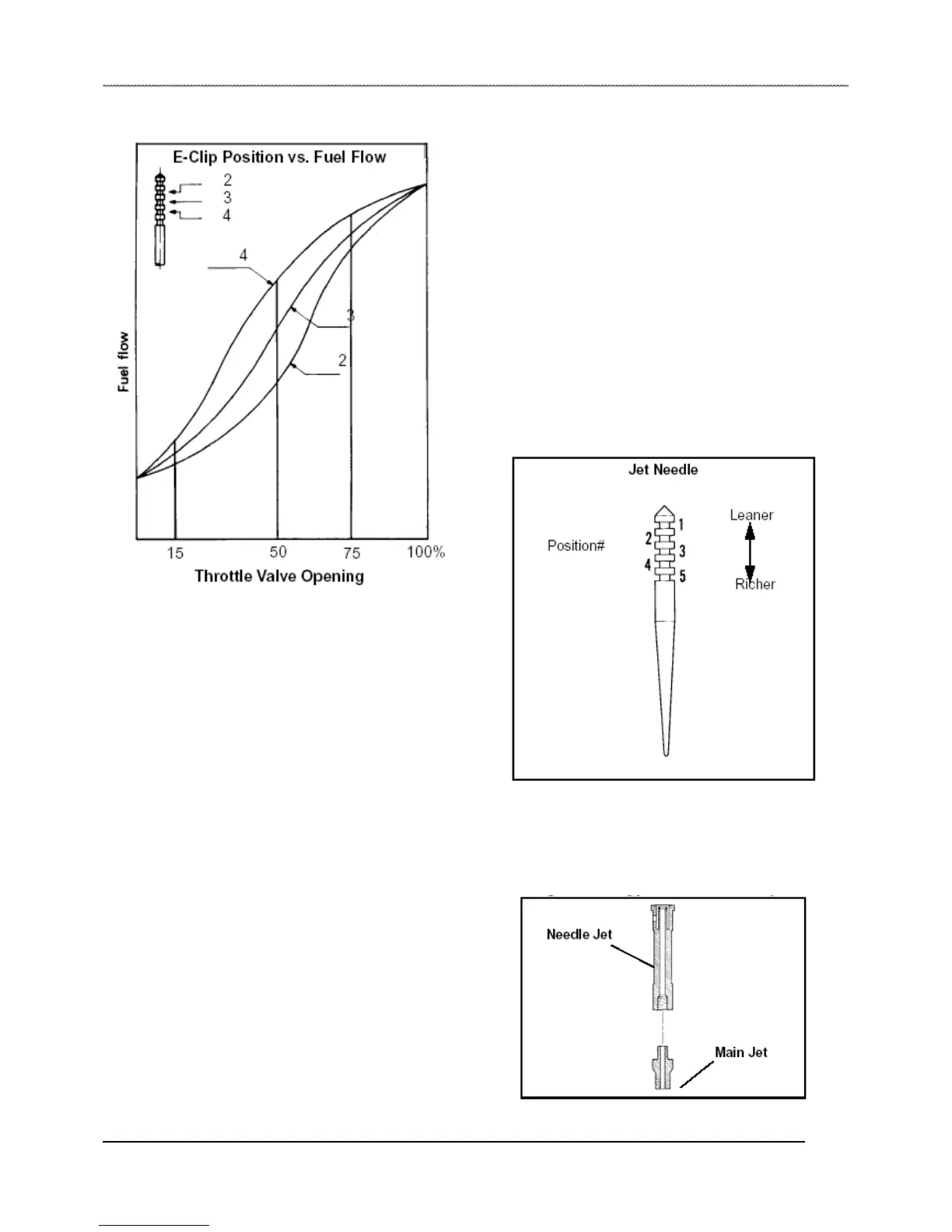

Jet Needle

The jet needle has five adjustment grooves cut into the upper

portion, and is tapered from approximately the middle of the

needle to the lower end. The top is fixed to the center of the

throttle valve by the needle clip, and the tapered end extends

into the needle jet. Fuel flows through the space between the

needle jet and jet needle. This space does not vary until the

throttle reaches the 1/4 open point. At that time the tapered

portion of the needle begins to move out of the jet, affecting

fuel flow as the opening enlarges. If the needle clip is changed

from the standard position to a lower groove, the needle taper

starts coming out of the jet sooner, resulting in a richer

mixture. Moving the clip higher produces a leaner mixture. If

the taper is worn due to vibration, fuel flow may be

significantly affected.

A carburetor with a slide type throttle valve is also called a

variable venturi type carburetor. In this type of carburetor, the

needle jet and jet needle serve to control proper air/fuel

mixture ratio at the medium throttle valve opening (between

1/4 and 3/4 opening).

Having the proper needle jet and jet needle has a major impact

on engine performance at partial load. The jet needle tapers off

at one end and the clearance between the jet needle and the

needle jet increases as the throttle valve opening gets wider.

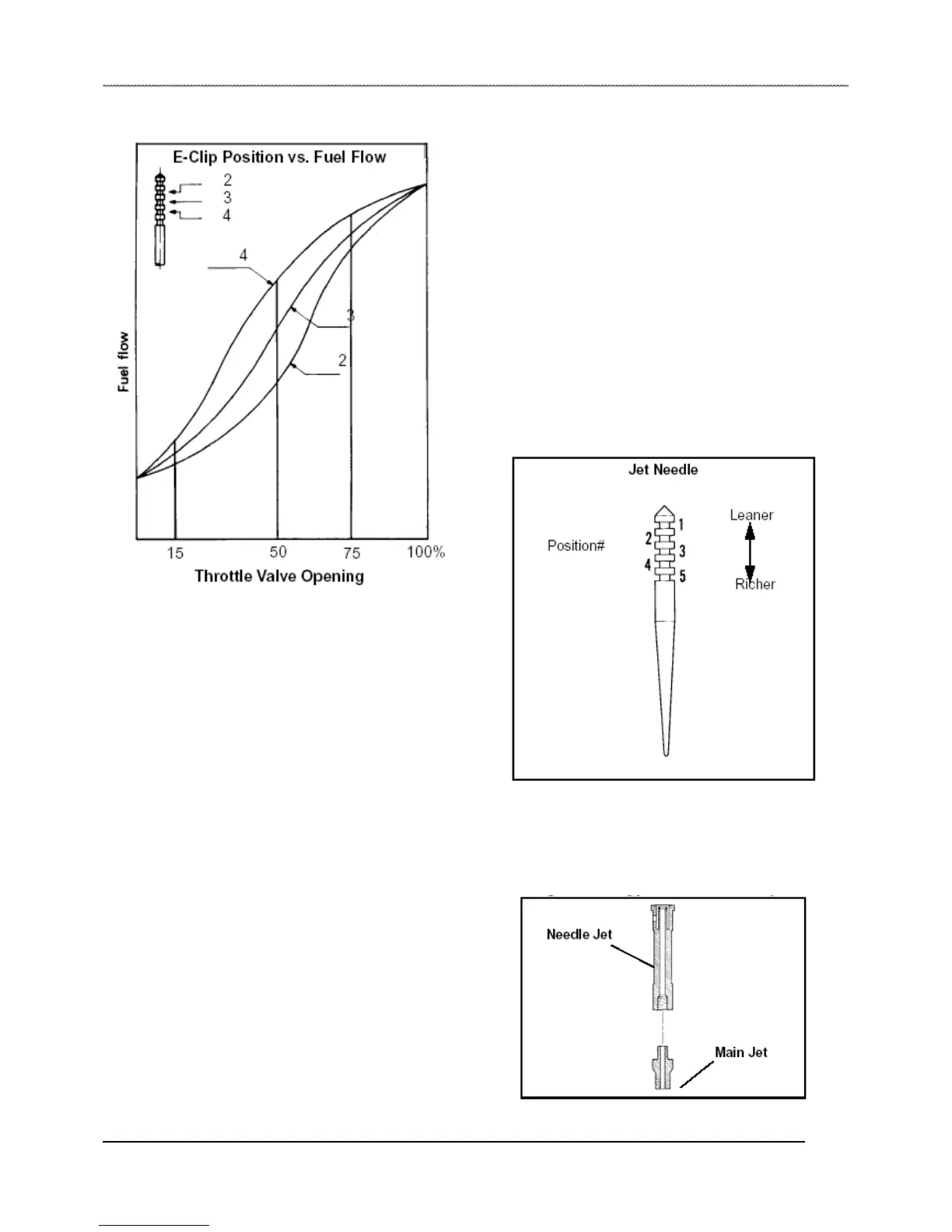

The air/fuel mixture ratio is controlled by the height of the “E”

clip inserted into one of the five slots provided in the head of

the jet needle. The previous chart shows the variation of fuel

flow based on the height of the “E” clip.

Needle Jet

The needle jet works in conjunction with the jet needle to

regulate fuel flow rate. An air bleed opening in the side of the

needle jet brings in air measured by the air jet. This air initiates

Loading...

Loading...