5.11

FUEL SYSTEM

Carburetor Cleaning

Protect eyes from contact with cleaner. Take

safety measures during these procedures. Safety

glasses and chemical resistant gloves are required.

Should you get cleaner in your eyes or if you swallow

cleaner, seek medical attention immediately.

Carburetor cleaners can be extremely caustic.

Extended periods of soaking can loosen the adhesive

sealer on the passage drill-way plugs.

Do not soak rubber or plastic components or O-rings in

caustic cleaning solutions. Irreparable damage may

occur. Do not use agitator-type carburetor cleaning

equipment.

Rubber parts must be cleaned with mild detergent and

hot water only.

Carburetor Inspection

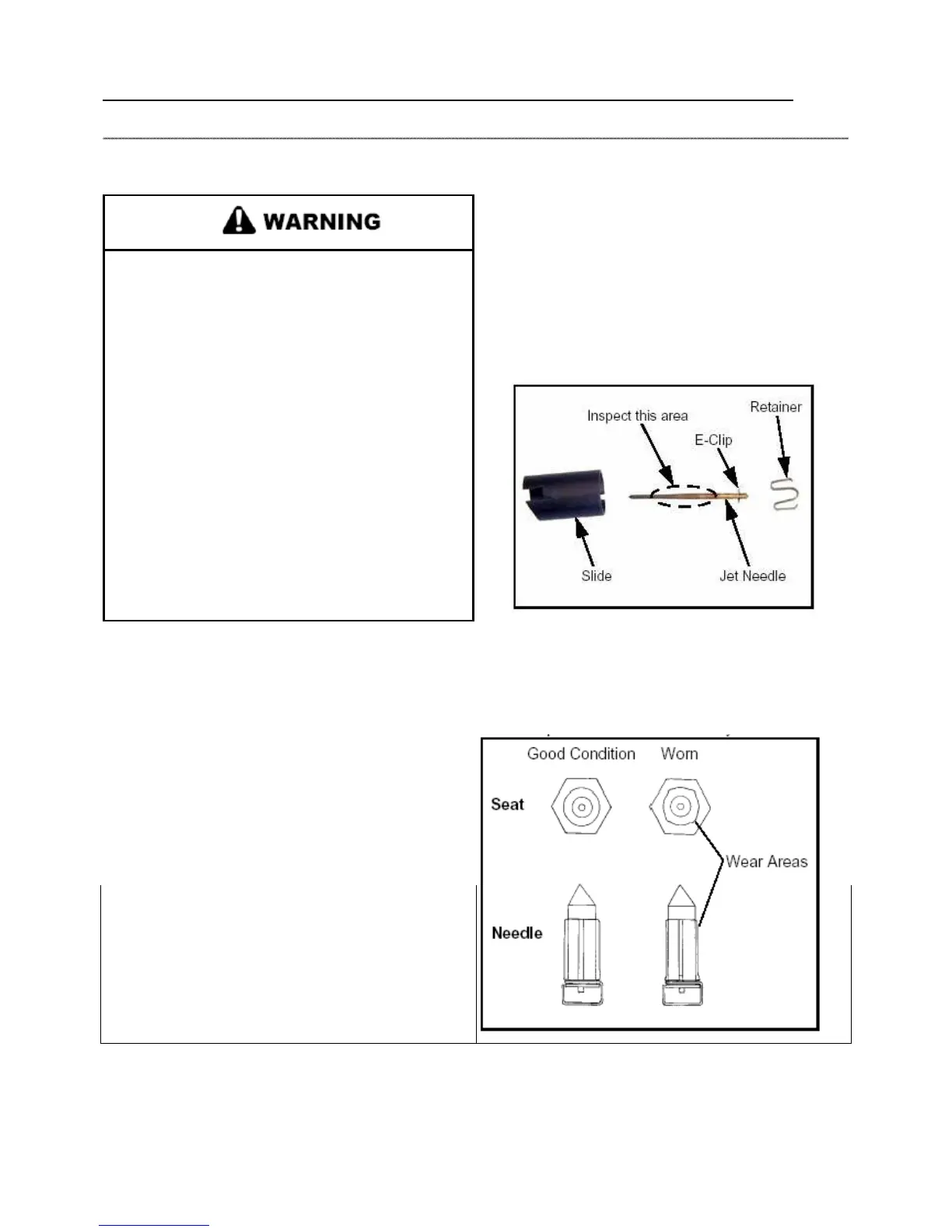

1. Remove the carburetor slide assembly. Disassemble the

components and inspect for wear. Inspect slide needle and

for discoloration, shiny spots, or an area that looks different

than the rest of the needle. The middle to upper portion of the

needle contacts the needle jet and is the most likely wear point.

If slide needle shows signs of wear replace both the needle and

needle jet to prevent a rich condition.

1. Thoroughly clean the carburetor body, jets, and all passages

with carburetor cleaner or electrical contact cleaner.

2. If the carburetor is extremely dirty or contaminated with

residue and varnish, soak for short periods only in carburetor

cleaner, and rinse in hot water.

3. Replace the jets if they have a buildup of fuel residue or

bacterial growth that cannot be removed. Even a small amount

of residue will reduce the flow characteristics of the jet.

4. Verify all passages and jets are unobstructed by spraying

electrical contact cleaner through the passages.

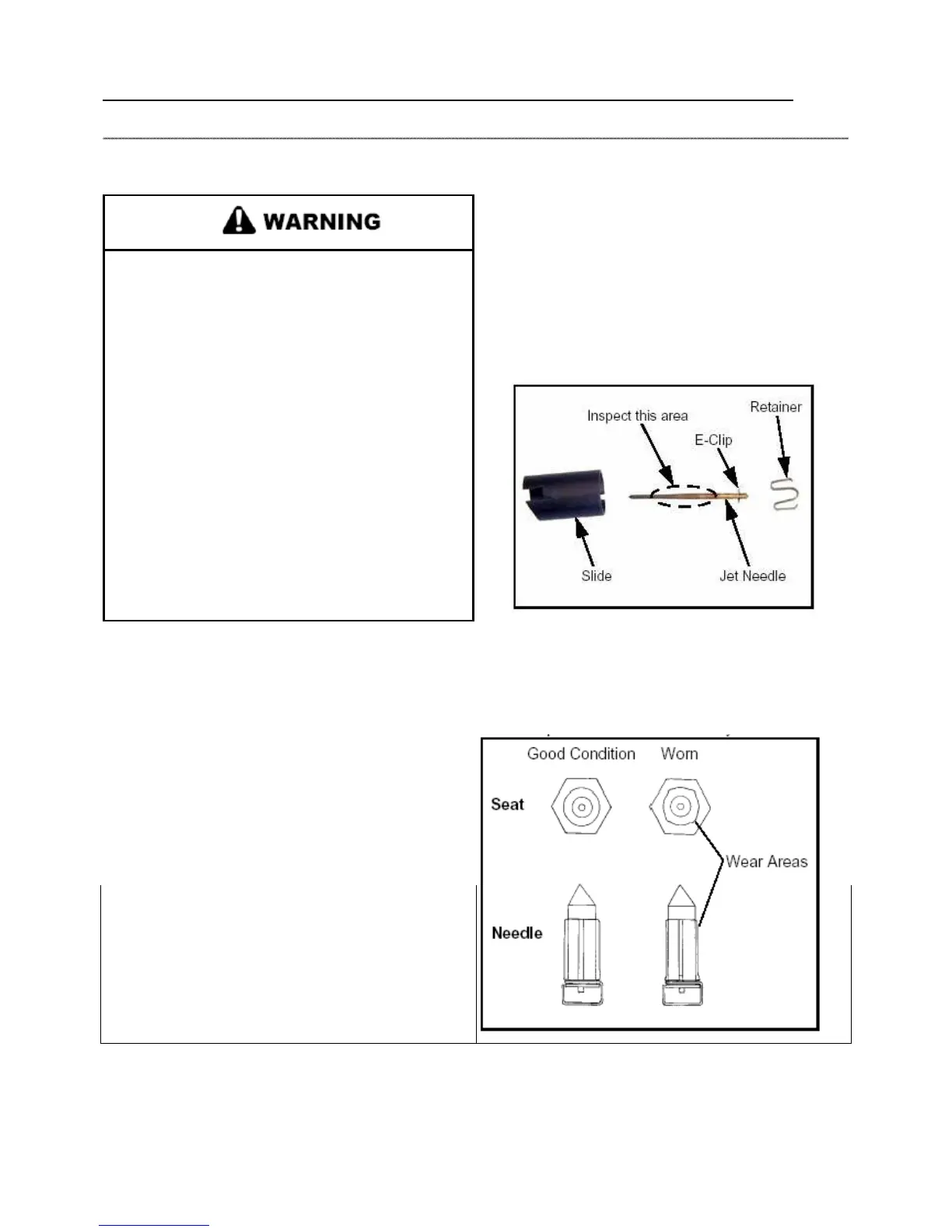

2. Inspect the inlet needle tapered surface for any sign of wear

or damage. Be sure the spring loaded pin is free moving and

returns freely when pushed. The inlet needle and seat should

be pressure tested after assembly.

IMPORTANT: Do not use wire or welding tip cleaners

as the orifice size may be altered.

5. Use low pressure air to dry carburetor body and all

components.

Loading...

Loading...