ENGINE / TRANSMISSION

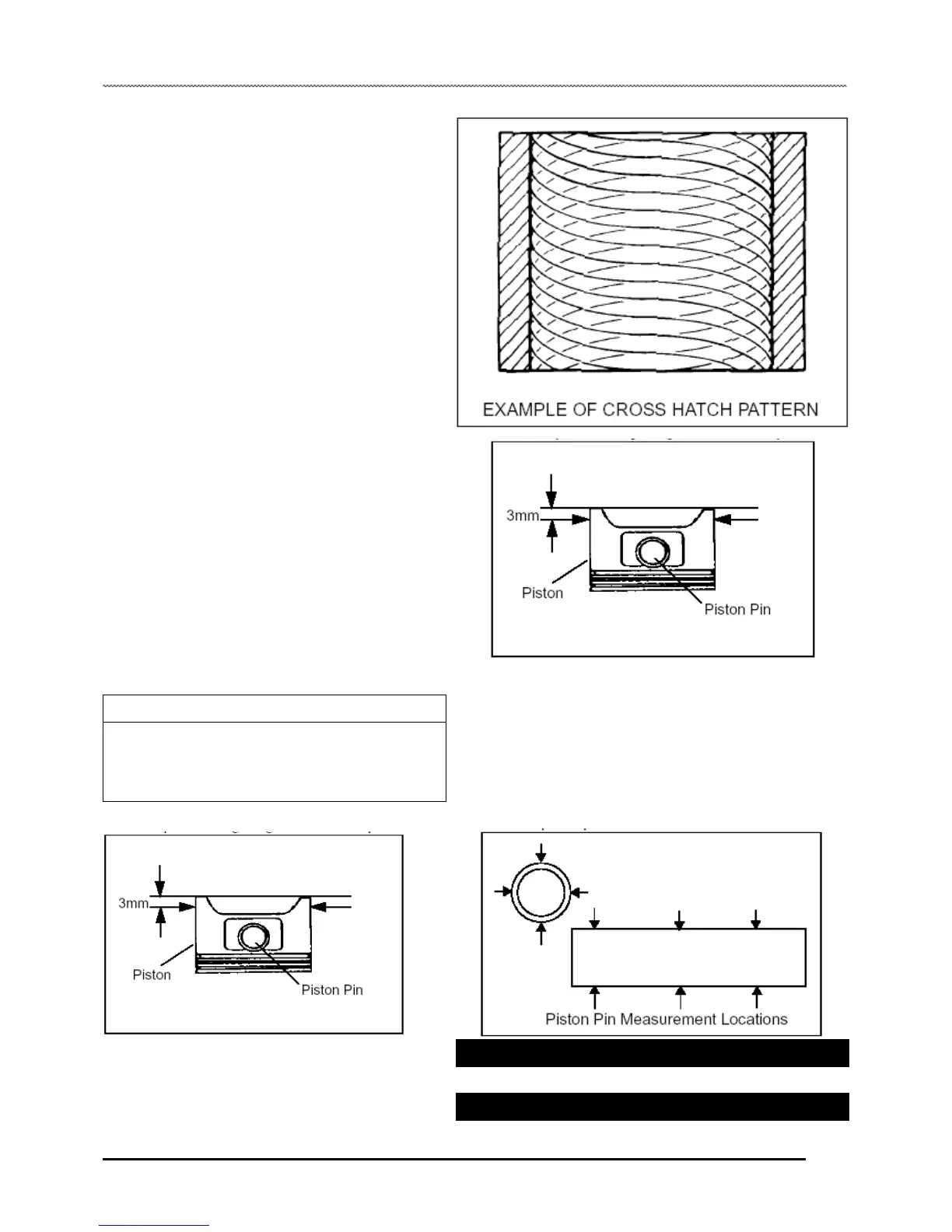

• Release the hone at regular intervals and inspect the bore

to determine if it has been sufficiently deglazed, and to

check for correct cross-hatch. NOTE: Do not allow

cylinder to heat up during honing.

IMPORTANT: Clean the Cylinder After Honing

Clean cylinder thoroughly after honing to remove all grit

material. Wash cylinder in solvent, then in hot, soapy

water. Rinse thoroughly and dry with compressed air. Oil

bore immediately with engine oil to prevent rust. If

cylinder wear or damage is excessive, replace cylinder.

Hone only enough to deglaze the cylinder bore.

Piston Inspection

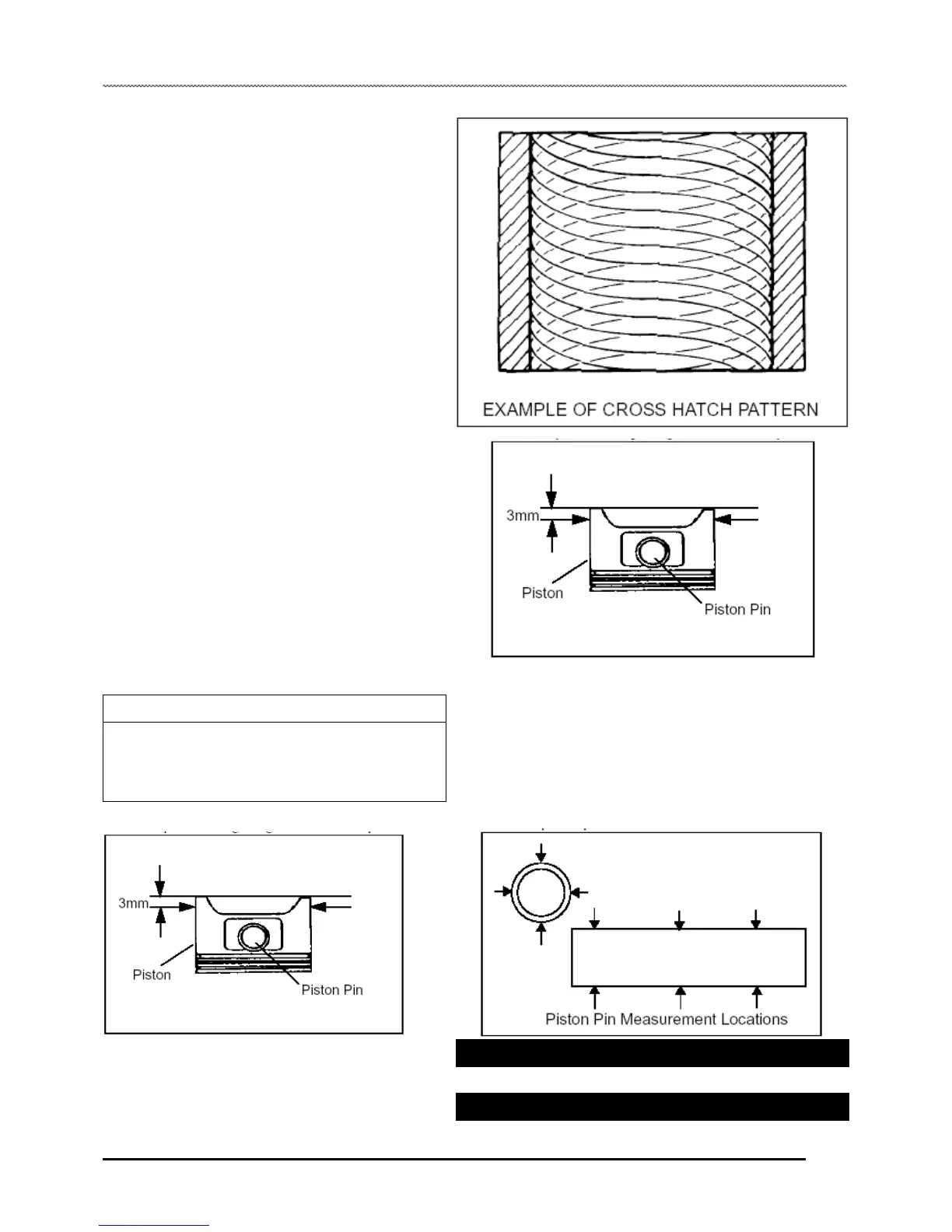

1. Measure piston outside diameter at a point 3mm up from

bottom of piston at a right angle to direction of piston pin.

2. Carefully inspect the pistons for damage or excessive

wear. Discard piston with cracked, broken or bent ring

lands.

3. Check the piston skirt for cracks, gouges, deep scratches

or heavy scoring.

4. Check the piston heas for evidence of burning, etching

or melting.

Piston OD.wearing limit: Less 40mm

Piston to Cylinder Clearance

Std: 0.01- 0.04 mm

Limit: 0.1 mm

5. Measure piston pin bore.

6. Measure piston pin O.D.

Pin OD. Limit: Less 9.994mm

Pin and Hole clearance limit: Over 0.01mm

Loading...

Loading...