5.12

FUEL SYSTEM

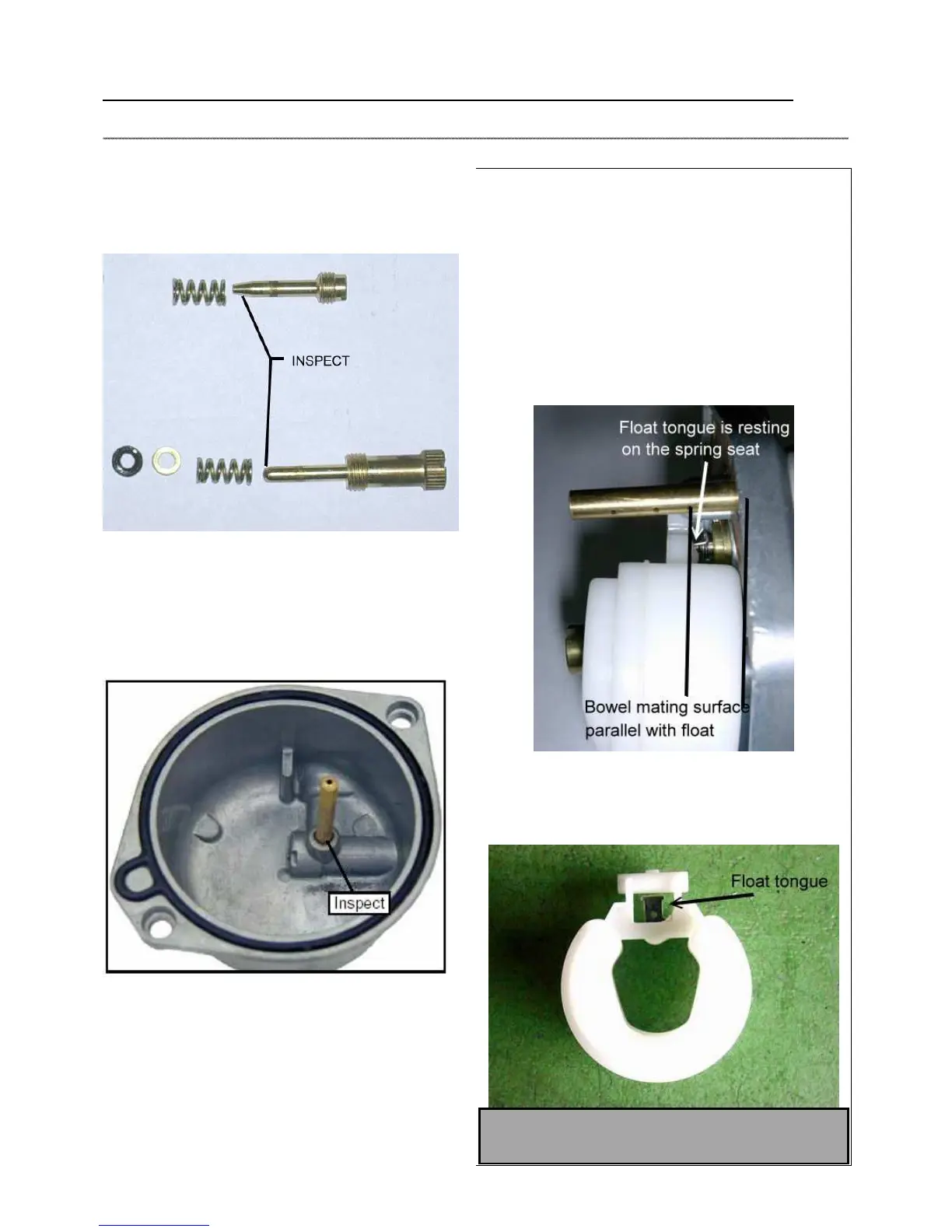

3. Inspect the idle speed adjust screw tip for flat spots and the

pilot mixture screw tip for damage. If any damage is

present on either screw, it must be replaced.

Float Height Adjustment

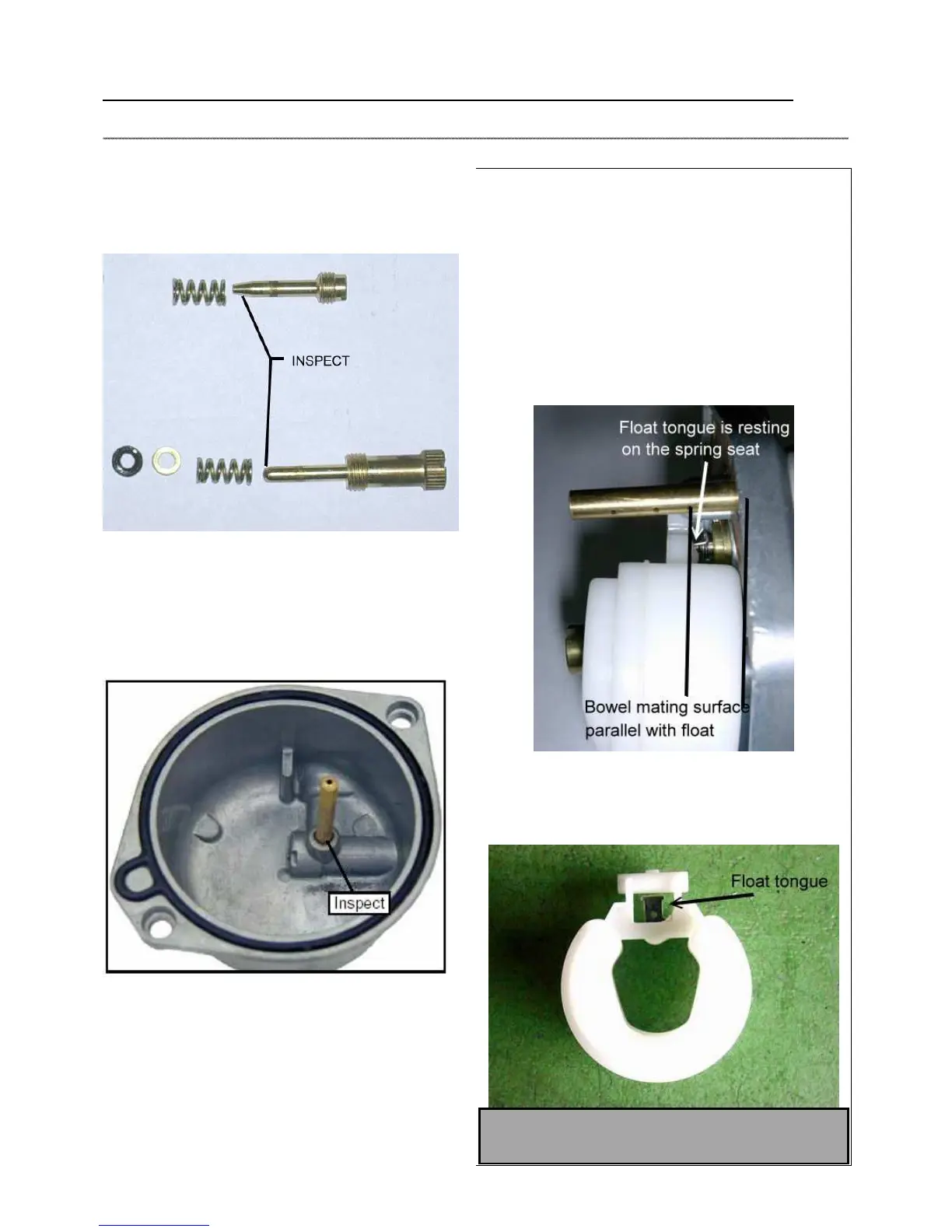

1. Place the carburetor at a level position to remove weight

from float arm. In this position, the float tongue will rest

slightly outward.

2. With the carburetor at rest and level, slightly tilt the

carburetor back. The float should fall into the correct position,

with the float tongue resting lightly on the inlet needle valve

pin without compressing the spring. The bottom of the float

should be parallel with the float bowl mating surface.

IMPORTANT: When measuring the height, verify the

inlet needle valve spring is not compressed.

NOTE: If the float is past parallel with the mating

surface, the carburetor has likely been tilted back

4. Inspect the float bowl vent tube for cracks near the bottom

of the tube.

NOTE: A continuous fuel leak from the carburetor

drain hose can be a result of a cracked bowl vent

tube.

Loading...

Loading...