Routine Maintenance: Inlets

Maintaining a PTV

Released: March 2004 6850 Series II GC User Information page 155 of 256

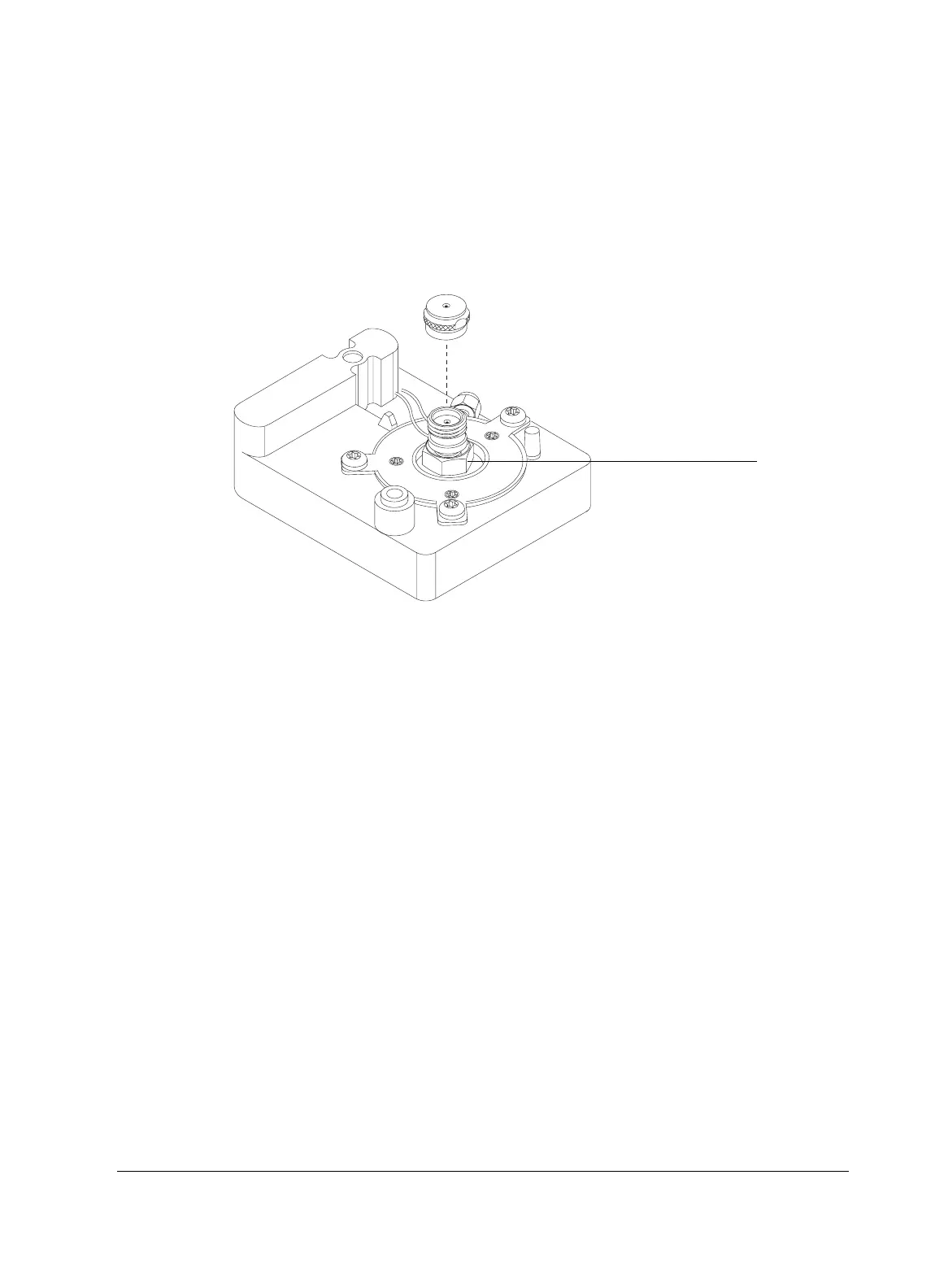

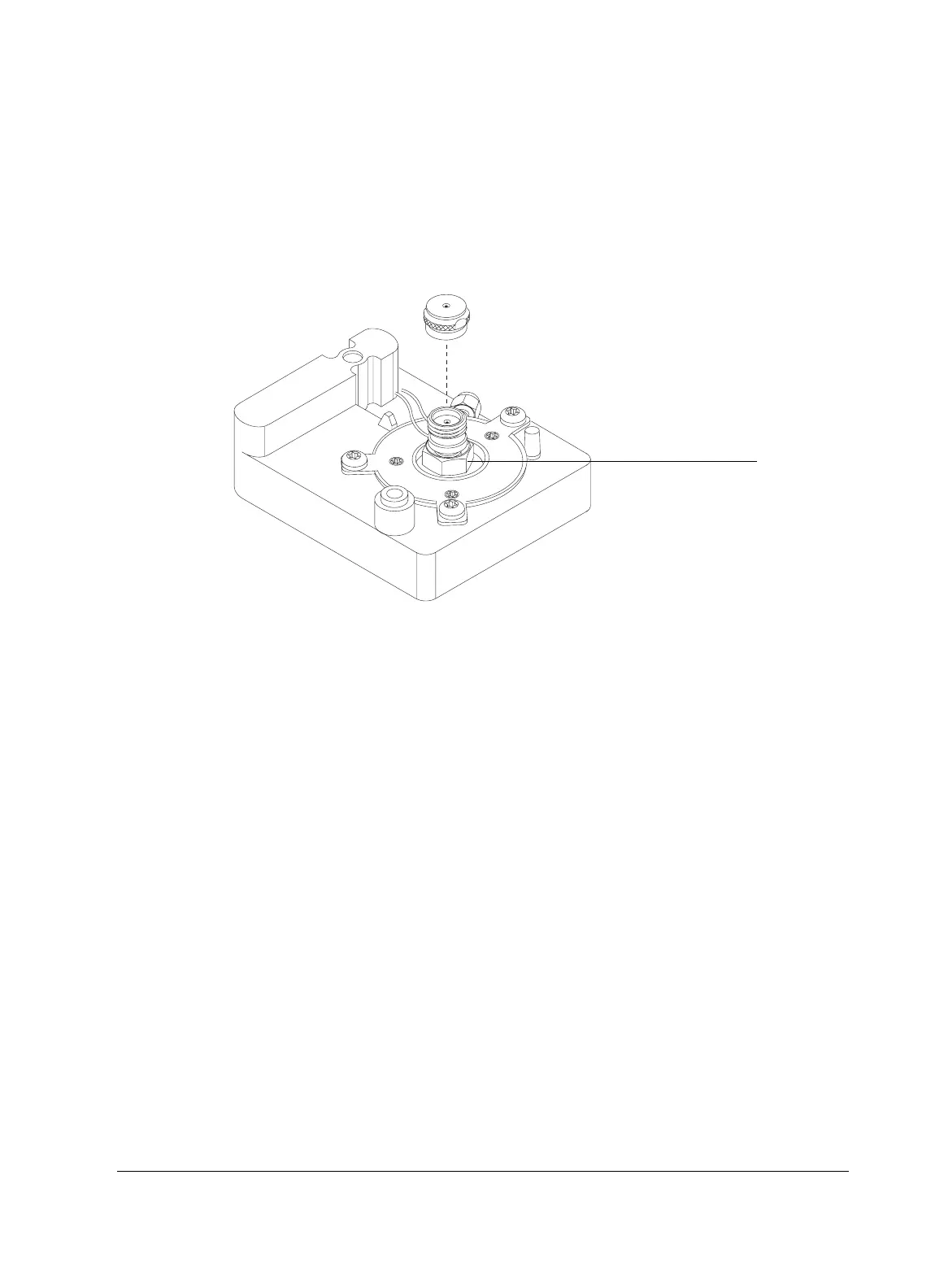

The septum head

The septum head uses either a regular septum or a Merlin Microseal to seal the

syringe passage. A stream of gas sweeps the inner side of the septum and exits

through the septum purge vent on the pneumatics module.

Removing the septum head

The septum head connects to the inlet via a free-spinning retaining nut.

1. Load the SERVICE method or reset the inlet and oven temperatures to

OFF or turn the main power switch off. Let the heated zones cool to room

temperature. Also, make sure that:

• If you have entered parameters that you do not want to lose, store

them as a method

• If the detector is on, turn it off.

2. Use a 5/8-inch wrench to loosen the retaining nut on the septum head.

3. Gently remove the septum head assembly from the inlet. Be careful not to

overly bend the 1/16-inch lines. For best results, lift the head to clear the inlet

and then push it to either side to allow access.

4. To reinstall the septum head, gently align the head with the inlet and

manually engage the free-spinning nut to the inlet.

5. The nut should easily turn on to the inlet. If resistance is felt, unscrew the

nut and retry. Excessive force can irreparably damage the inlet.

6. Tighten the retaining nut ½-turn past finger tight.

7. Check all connections for leaks. If necessary, the retaining nut can be

tightened an additional ¼-turn to eliminate leaks.

Retaining nut

Loading...

Loading...